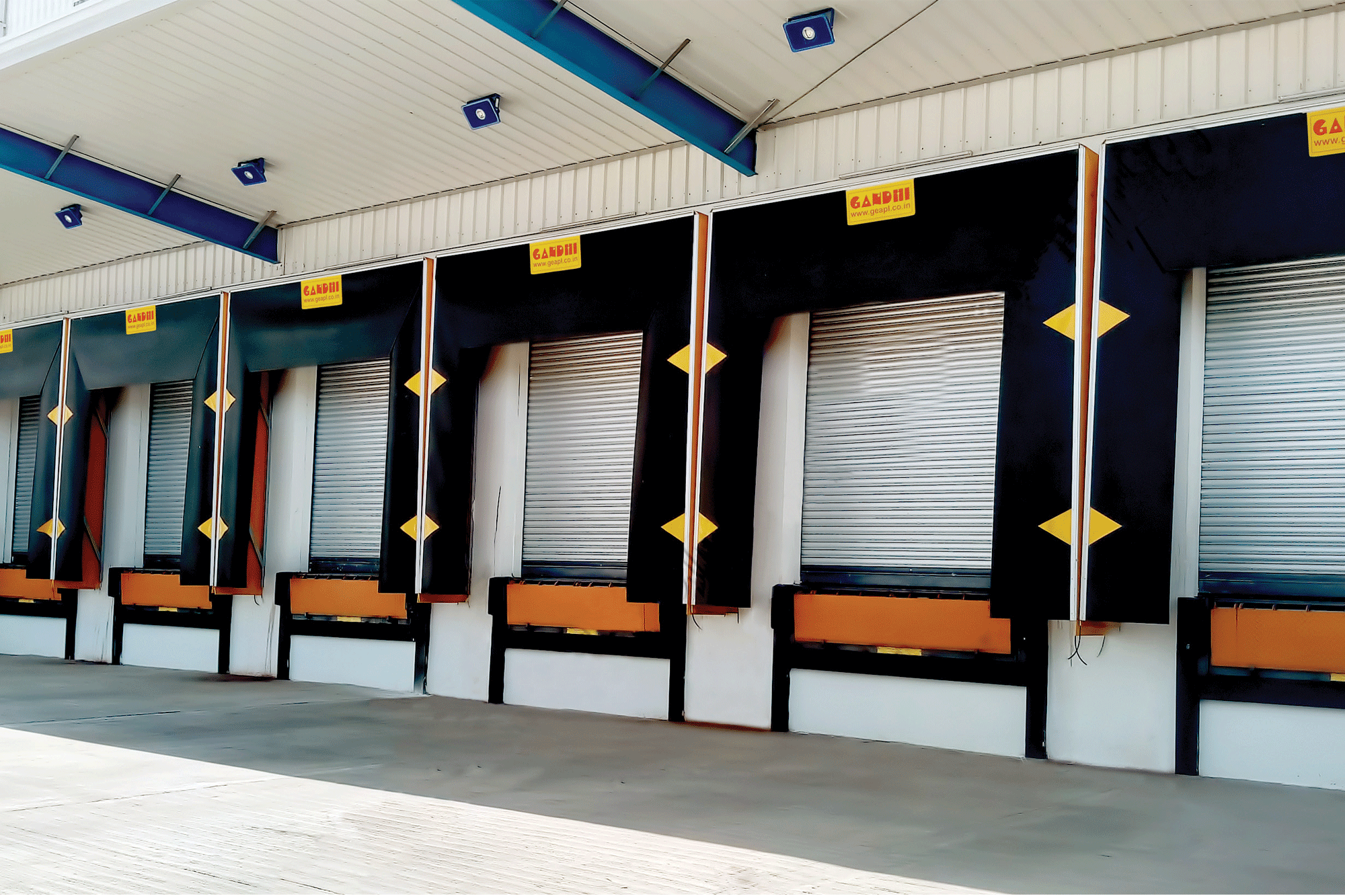

Dock shelters: Optimising the efficiency and safety of your loading bay

By Edit Team | September 27, 2019 6:08 am SHARE

Dock shelters help to increase the efficiency and safety of your loading bay the efficiency and safety of your loading bay

Dock shelters are incredibly effective products that form a vital part of any loading bay.

If you receive goods on a daily basis you should already be well aware of how difficult it can be to prevent sudden temperature fluctuations when a loading bay door is opened. However, did you know that selecting the right dock shelters for your operating environment can help reduce your utility bill by as much as 40%?

Why invest in dock shelters?

Dock shelters within loading dock systems are an integral part of any facility. Loading Dock Shelters reduces over sized doors to match truck opening. Providing protection for your products, they guard against outside conditions, including insects, pests, & other variables, solves your environmental control needs, and help to improve internal temperature and worker environment.

Our Dock Shelters will provide a safer dock environment and unrestricted access to the trailer. Dock Shelters help keep the elements out while providing full, unimpeded vehicle access for a safe and productive loading dock. Designed to withstand daily wear and tear, Gandhi Automations dock shelters provide a high-quality, effective solution to our customers’ unique environmental challenges.

Dock shelters are designed to withstand heavy impact from trailers and protect your commercial business from damage. The shelter also forms a ground level canopy to protect personnel and loads from the elements when loading and unloading.

Here at Gandhi Automations, our dock shelters are designed to provide an effective and durable seal between the internal and external environments of your loading bay. Our inflatable dock shelters can significantly reduce the amount of air that ingresses or egresses from your building during the loading-unloading process

Our dock shelters can be designed bespoke to create a tight fit around your fleet of vehicles which helps to protect your delicate goods from exposure to contaminants.

Gandhi Automations dock shelters are manufactured to the highest standards to cope with the demanding requirements of a 24/7 operating environment and can be designed to suit all types of vehicles.

The other benefits of our dock shelters

Our dock shelters do much more than simply reduce your energy consumption and make it safer and easier to load and unload goods.

By maintaining the temperature inside your building, you will be able to improve the working conditions for your employees, reduce the spread of illness and keep the number of absences to a minimum – meaning that you will also improve staff morale, achieve your deadlines and save money.

What types of dock shelters do we offer here at Gandhi Automations?

All of our dock shelters can be customized to cater to the needs of your existing loading bays and vehicles. We have three variations of dock shelter you can choose from:

Retractable dock shelters:

Our most popular shelter and one which is best suited to ambient temperature environments. Very flexible and accommodates a wide range of vehicle heights and widths. Collapsible dock shelters provide an effective weather seal and also prevent the risk of rain and vermin from entering into the building.

The retractable dock shelter is best suited for facilities with large doors and where the entire truck/trailer door opening must be unobstructed. This dock shelter retracts upon impact from off-center trucks without sustaining damage. retractable dock shelters with inclined roofs are formed by a perimeter structure that holds a series of canvases which adapt to the truck’s bodywork. This structure is retractable so that if any incorrect manoeuvre is performed by the truck, the shelter returns to its initial position.

The aim is to provide a perfect seal when loading and unloading to achieve considerable energy savings and the resulting protection of the goods.

Cushion dock shelters:

A cushion dock shelter from Gandhi Automations offers the best insulation when a dedicated vehicle fleet is used to ship goods. When swap-trailers and mobile containers are often loaded at your loading bay our cushion dock shelter is the best solution.The cushions are fixed on galvanized steel back plates and therefore suitable for use at locations with strict environmental requirements.

Cushion dock shelters are developed to work specifically for parcel distribution centers, where vans reverse up to the loading bay with their back doors open. They help facilitate an efficient, uninterrupted flow during loading and unloading and reduce the risk of damage to your loading bay and delivery fleet as vans can back up safely to the loading bay.

Once a van / truck is docked, cushion shelters create a tight seal between the open back doors of the van and the loading bay entrance, enhancing your facility’s security and indoor environment.

The cushion dock shelters ensure best draught seals and insulation is achieved. Even sealing of the smallest gaps between the vehicle and building is achieved.

Inflatable dock shelters:

Inflatable dock shelters are designed to always ensure an optimal seal during the loading and unloading process. The inflatable dock shelters are provided with an inflatable coupling system using an air turbine. They include a single phase low pressure fan and an elastic unit to bring the dock shelter back to its initial position.

The perfect adaptation of our inflatable dock shelters to the truck blocks provides considerable energy savings by thermally isolating the exterior and providing greater interior hygiene, always without affecting the comfort and flexibility of the manoeuvre.

Well suited to temperature-controlled environments or situations where preventing contamination of goods is important. Inflatable dock shelters provide the optimal seal between the internal and external environments and are the best solution for cold storage warehouses. An inflatable dock shelter provides a high level of flexibility and is able to interface with a much wider range of vehicle heights and widths.Inflatable dock shelters provide high sealing, which make them perfect for loading bays in the pharma, cold storage, food, agriculture or chemical industries, among others.

Isolating the warehouse environment from the outside, it is not only useful to the human working conditions, but also for avoids entry of dust and heat, therefore resulting in energy saving, ecological safeguard, guard of fragile goods and better working efficiency. Gandhi Automations offers a complete variety of Dock Shelters available for all kind of usage and situation from the outside cold conditions or the chilled ones from outside heat and also from shower, breeze, snow and dirt.

At Gandhi Automations we understand the importance of specifying the right products to suite your operational needs. Whether you need a standard or bespoke solution we are here to help you identify what is best for you.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.