Technology Goes On The Road

By Edit Team | July 8, 2017 7:58 am SHARE

Featuring technologies used for building the advanced roads

Roads and Highways sector has been and continues to be one of the key drivers for growth for the infrastructure sector in India. India needs roads and highways, both in rural and urban areas to progress. The government also realises the importance of world-class road network and thus, has given significant focus to the sector by way of announcing substantial budget outlay in successive National Budgets. Investments that have been earmarked for this sector present a great opportunity for the OEMs. Here we discuss how the industry is gearing up to leverage this opportunity in the area of road construction highlighting advanced road making technologies.

Soil Compactor with German Vibration Technology

JCB is fully geared up to leverage the increasing opportunity in Indian market with its world-class product range. The company has made a new and innovative addition in its Compactor portfolio in 2016 with the launch of JCB 116 Soil Compactor. “The JCB116 Soil Compactor is equipped with proven German Vibration Technology and is designed to give more compaction per litre. It guarantees desired compaction density in a minimum number of passes,” says Jasmeet Singh, Head – Corporate Communications and External Relations, JCB India Ltd.

In-built Compaction Meter

JCB India claims to be the first manufacturer in the industry to offer an in-built Compaction meter in its range of compactors. Designed and developed in India, the Compaction meter ensures uniform compaction as the operator exactly knows where to stop and the number of passes that are required to achieve the desired density. This leads to a uniform compaction density and savings in Fuel as well as time. It helps in reducing the number of passes and also avoids over compaction.

Telematics

Telematics technology has transformed the construction equipment industry by enabling real-time access on the performance and operation of construction equipment. “All our compactors come with a revolutionary telematics technology – the JCB Livelink,” informs Jasmeet.

Livelink technology in JCB machines would benefit the customers in better management of their machines which would lead to better expense management and timely completion of work. This state-of-the-art technology enables users to get SMS alerts on their mobile phones or smart devices regarding service alerts, operations and security of their machines.

The information is available in real time regarding the health of the machine including engines and gives vital information to the customer in terms of no. of hours the machine has been operational, service intervals, fuel levels, malfunctions if any, etc.

Kobelco’s Generation 10 series Excavators

Excavators are very versatile machines which find several applications in the road building activity. It starts with site clearing and cutting as well as excavation depending upon the terrain. In rocky areas, they are used with Rock Breaker attachments.

Hydraulic excavators manufacturing major Kobelco has recently launched its latest model under the Generation 10 series with even higher productivity and durability for much higher Return on Investment (RoI) for the owners, informs Vikram Sharma, Advisor, India & South Asia, Kobelco Construction Equipment India Pvt Ltd.

Kobelco’s advanced features like low emissions, very low sound levels, and low fuel consumption help in faster execution of work at lower operating cost and with minimal impact on the surroundings, which are usually close to human habitations, Sharma claims.

New generation concrete batching plants

Universal Construction Machinery and Equipment Ltd offers advanced technology batching plants which are specially designed to meet requirement for road sector. The new generation concrete batching plants can be customised as per requirement. Three different types of mixing technology like twin shaft mixer, planetary mixer and pan mixer along with four different type of feeding system like inline, cross bin, rover, mobile and universal type. The company is also providing three different types of fully automatic SCADA, USB or HMI control panels. Their control panels designed in such a way one can control multiple batching plants from central locations and different type of report can be generate. Explaining the USP of Universal Batching Plant, the company’s Vice President – Sales & Marketing Sunil Bhamare, “Main USP of Universal Batching plant is faster and easy erection / dismantle at site. It has all frame structure assembled from factory in parts. It can be installed at site with pick and carry crane available locally and can be setup quickly.”

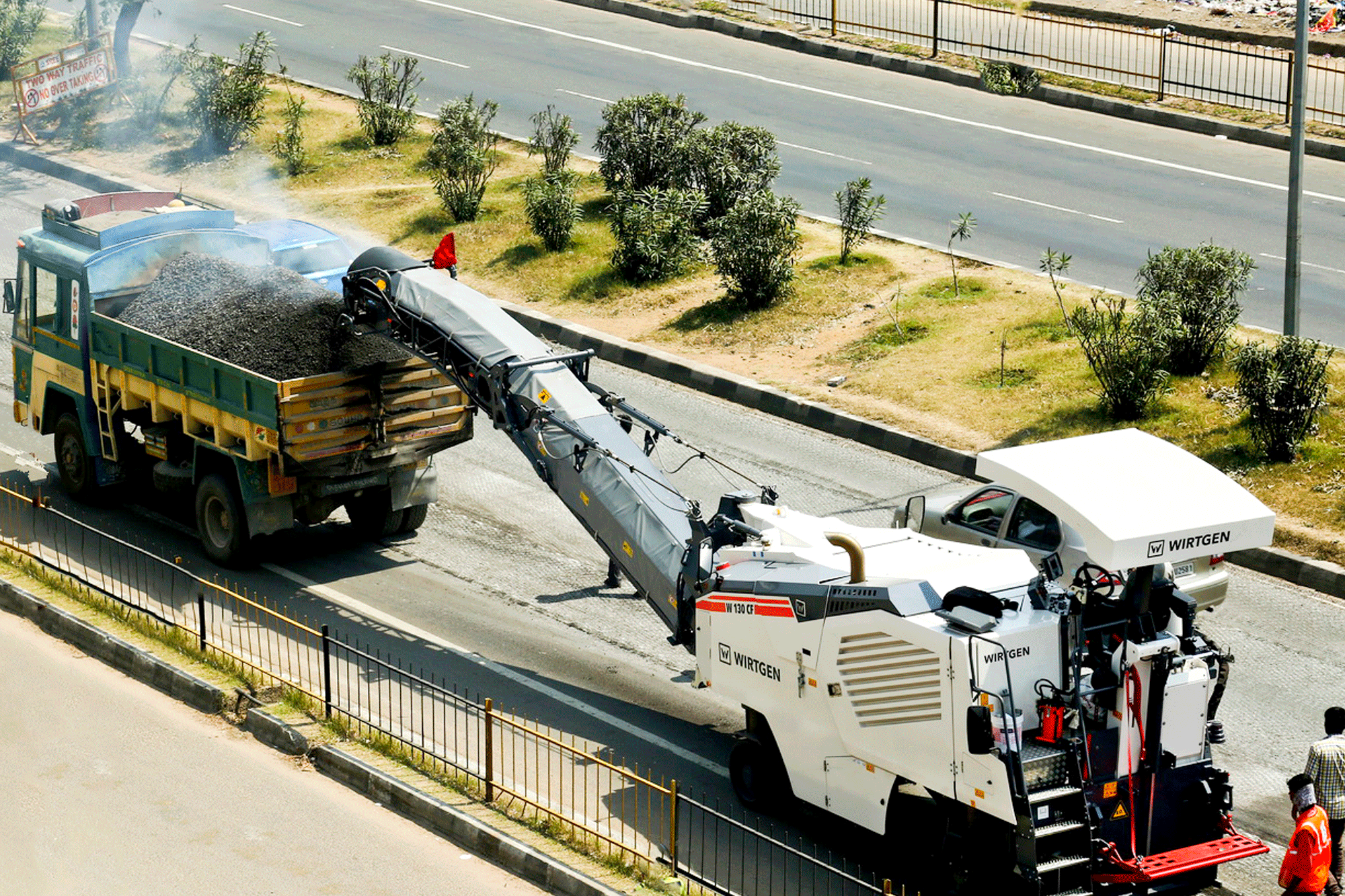

New Gen Slipform Paving, Cold Milling & Cold Recycling

Wirtgen Group introduced Concrete Slipform Paving machines at least a decade back where the prestigious Mumbai-Pune Expressway was built using Wirtgen Slipform Pavers. Most of the concrete roads of the Golden Quadrilateral are built by using the Wirtgen Slipform Paving technology.

Cold milling technology is another innovative and cost effective technology that was introduced to the Indian market around 5 years back and is more popular and has received more acceptances in the Indian market. Cold recycling is another latest technology we have introduced to the Indian market where we initiated some projects with big BOT operators like L&T, IDPL and ITNL for National Highways.

Wirtgen has been consistently trying to develop products which offer better efficiency in terms of fuel consumption and this helps in sustainable development and less carbon emissions. “Our machines contribute towards reduction of use of aggregates and also in the reuse of existing bitumen with our cold milling and cold recycling technologies,” Ramesh Palagiri, Managing Director and CEO, Wirtgen India.

“The average age of any of the Wirtgen Group products in the market is around 2 years which means that most of our products are from the new generation and in most cases the Wirtgen Group products are atleast a generation ahead of competition,” Palagiri claims.

Wirtgen Cold Milling machines, Wirtgen Soil Stabilisers and Cold Recyclers, Surface Miners, the new Dash 3 series of Vogele Pavers, the EVO series of Kleemann crushing and screening plants are all new generation products which are technically ahead of competition. “We are introducing New Gen products to help our customers to improve productivity and reduce their operating costs,” he said.

Intelligent Compaction System

Intelligent Compaction System (ICS) is one of the recent technological innovations with several advantages over conventional compaction technologies. However, it being still at a nascent stage suffers from lack of adequate knowledge among engineers and is costlier than conventional compactors. The equipment used in small scale projects are selected by contractors. Hence the recommendation and acceptance of ICS has to come from the contractor fraternity, who has to educate themselves and get to understand the advantages this technology offers. ICS automatically generate reports on temperature of the strata and the number of passes. CASE India offers these systems as an optional attachment along with its equipment, says Shalabh Chaturvedi, Head of Marketing, CASE India.

Recently upgraded CASE 1107EX soil compactor ensures powerful, fuel-efficient performance. It features a new FPT Industrial S8000 3.9-litre engine that delivers 100 HP at 2,200 RPM and torque of 435 Nm at 1,300 RPM. The turbo after cooled engine with internal Exhaust Gas Recirculation ensures best-in-class fuel economy. The more than 2 million S8000 engines at work across the world are testament to the reliability of this proven power plant. The maximum applied force in the range of 34 tonnes is among the best in the industry. The hydrostatic variable speed control ensures the CASE 1107EX travels at the perfect speed for every type of soil, resulting in a uniform compaction.

This high productivity comes with high reliability and serviceability. The easy to open engine hood provides excellent access to service points. The pump group located at the rear of the machine is extremely easy to service. The operator station provides excellent comfort and safety. The outstanding all round visibility, together with the 90-degree rotating seat, makes it easy for the operator to control the rear wheel and front drum, operating productively and safely. The CASE 1107EX is also available with advanced features such as the compaction meter and Eagle Eye Telematic System, a real-time vehicle tracking and communication based on GPS technology that helps deliver better value for money.

ABA UniBatch

Reducing costs and boosting profit are always at the forefront of Ammann plant designs. The ABA UniBatch utilises an exceptionally efficient drying and heating process that conserves energy. The burner control regulates the mix process to ensure reduced consumption – and low emissions. “Plant operators also can choose the most cost-effective fuel, with options including natural gas, light fuel oil, heavy fuel oil and liquefied gas,” says Sunil Sapru, Region Director- India, Ammann Apollo India Pvt Ltd.

The ABA UniBatch is ‘future optimised’ – the plant can be easily retrofitted with the latest, most technologically advanced and profitable options.

AP800 and AP1000

Apollo Tracked pavers AP800 and AP1000 offer high technology that includes the MOBA dashboard, at affordable prices. The AP 800 which was introduced at bC India in 2016, features a high traction track system with the Apollo TV4900 screed for paving up to 7 metre width. The screed heating is with environmentally friendly LPG .The dashboard for the main operator and the screed operator platform allows a simple operation of the machine.

According to Sapru, “The AP 1000 for paving widths up to 9.56 metres is well established in Indian market for all type of surfaces. AP1000 is known for its reliability and output.”

Ammann ARS121 and ARS122 Soil Compactors

The USP of Ammann Compactors is to achieve compaction with the lowest number of passes. This can be easily verified in the machines that are operating in India. Ammann ARS121 and ARS122 Soil Compactors are products of this advanced technology, claims Sapru.

ARS121 and ARS122 offer a wide range of innovation for operator comfort and compaction performance. Conveniently located, intuitive controls provide ease of operation. Reduced vibration to the cab means lower operator fatigue. The machines are productive in multiple types of materials which is a hallmark for a soil compactor.

“Ammann soil and asphalt compactors provide needed efficiency through industry-leading technology and an ability to direct more force toward the target and away from the machine. The rollers provide quality results in fewer passes and a more productive and profitable jobsite,” assures Sapru.

Next Generation Wheel Loader

LiuGong has recently launched 856H Wheel Loader – the next generation machine powered with Cummins QSL 9.3 engine. It has variable hydraulic system, three operating modes – Economy, Neutral and Power. The wheel loader is equipped with 3 cu.m. bucket capacity and wide range of attachments for multiple working conditions, new ZF power train of 4WG208(F4/R3) gearbox and wet axles ideally matched to perform the perfect harmony and ensure optimised performance.

It has operating weight of 17,100 kg. Rear view camera, like an extra eye outside machine, creating a safer working environment as you concentrate on the work at hand. 856 H is equipped with Trimble which provides geo location and vehicle status (moving/stalled/stopped), real-time individual vehicle alerts and diagnostics, fuel consumption, preventative maintenance schedules, geo fencing and more, informs Nischal Mehrotra, Sales and Marketing, LiuGong India.

Indigenised, smart machines

According to Sachin Nijhawan, Vice President and Business Head, Mahindra Construction Equipment, “Current road making machineries are dominated by imports and foreign manufacturer where the products are being made keeping in mind the needs of the developed worlds. Whilst in the developed world 60 per cent of roads fall in our category of the multilane express and state and national highway, they constitute only 6 per cent of overall roads when it comes to India. The equipment currently available are too large and expensive hence grossly unutilised and non-viable for most village and unsurfaced road projects which constitute 58 per cent of total roads in developing countries like India. This also results in very low sales volume of equipment in spite of the large quantum of road work. Absence of tailor-made equipment suitable for our needs lead to sub-optimal methods with limited mechanisation and large labour force deployment. This leads to issues such as bad quality of roads and speed of road making apart from availability and control of labour force in large numbers.”

“You would soon hear from us about our range of category creating products in the road equipment category suitable for our market laced with the most modern technology as RemoteCare, DigiSense, Connected Machine etc. offering exactly what our customers requires i.e. higher profits and RoI with lesser investment,” Nijhawan announces.

Jasmeet Singh, Head – Corporate Communications and External Relations, JCB India Limited

JCB116 Soil Compactor is equipped with proven German Vibration Technology and is designed to give more compaction per litre.

Vikram Sharma, Advisor, India & South Asia, Kobelco Construction Equipment India Pvt. Ltd

Kobelco has recently launched its latest model under the Generation 10 series with even higher productivity and durability for much higher RoI for the owners.

Sunil Bhamare, Vice President – Sales & Marketing, Universal Construction Machinery and Equipment Limited

Universal is an ISO certified company that is striving since last 3 decades to provide a large spectrum of superlative products, keeping in mind the specific needs of the construction business.

Ramesh Palagiri – Managing Director and CEO – Wirtgen India

We are introducing New Gen products to help our customers to improve productivity and reduce their operating costs.

Shalabh Chaturvedi, Head of Marketing, CASE India

Intelligent Compaction System (ICS) is one of the recent technological innovations with several advantages over conventional compaction technologies.

Sunil Sapru, Region Director- India, Ammann Apollo India Pvt Ltd

Ammann soil and asphalt compactors provide needed efficiency through industry-leading technology and an ability to direct more force toward the target and away from the machine.

Nischal Mehrotra, Sales and Marketing, LiuGong

We have recently launched 856H Wheel Loader, 856 H is next generation machine powered with Cummins QSL 9.3 engine specially developed for LiuGong.

Sachin Nijhawan, Vice President and Business Head, Mahindra Construction Equipment

Absence of tailor-made equipment suitable for our needs lead to sub-optimal methods with limited mechanisation and large labour force deployment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.