The Art of Scaffolding: Layher Event Systems Ideal for Big Events

By Edit Team | October 30, 2019 11:46 am SHARE

The brand promise made by Layher (the name of German Company) is the expression of a brand philosophy that we’ve been living by for over 70 years. More speed, more safety, more proximity, more simplicity and more future: values with which we strengthen our customers’ competitiveness in the long term. With our innovative systems and solutions, we’re working all the time on making scaffolding construction even simpler, even more economical and, above all, even safer.

The Layher Event system is a construction kit which can use to erect a wide variety of stages and stands. With the Layher Event systems can choose between different sizes, where the systems differ from each other in terms of the ground plan (layout) and in particular in the design of the stands. Thanks to the removable plastic corners on the Event decks, you can construct practically all variants of desired stages and stands.

Layher stages

The width of the stage decks is a practical distinguishing feature and the basis for identification of the modules. The event decks up to 2.07 m and 2.57 m in length are designed to bear load of 5 KN/m². The removable Plastic corners ensure that the vertical tubes can pass through platform level if required. The coated plywood board is braced with aluminium rungs.

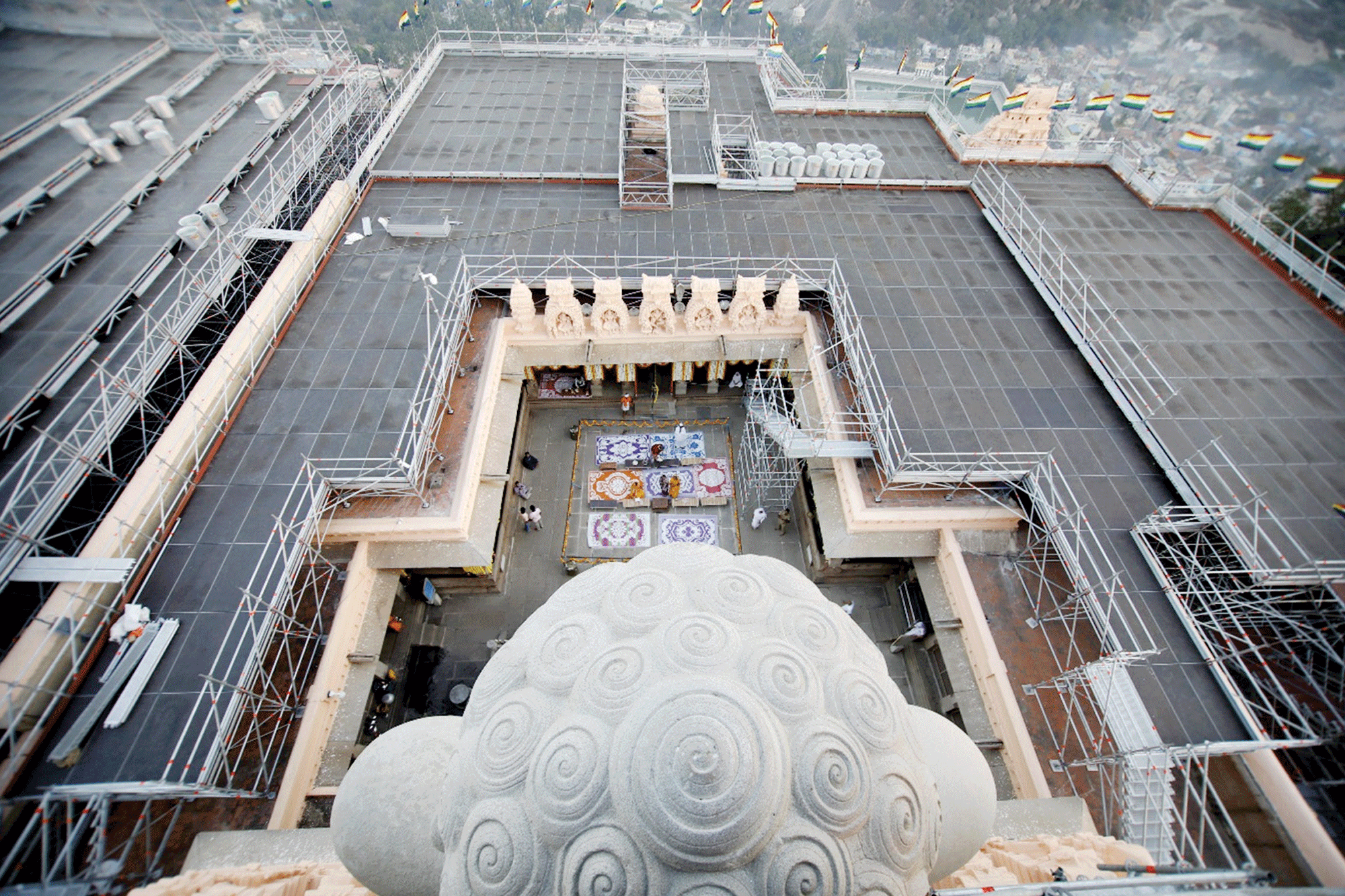

Application Layher Allround and Event Stage for Mahamastakabhisheka

Scope of the work: Installation of scaffolding and temporary platform for Mahamastakabhisheka at Shravanabelagola, Hassan District. Mahamastakabhisheka, the head anointing ceremony is performed once in 12 years to the 57 feet tall monolithic statue of Lord Bahubali at Shravanabelagola. It was built circa 981 A.D. and is one of the largest free-standing statues in the world.

Shravanabelagola, nestled by the Vindhyagiri and Chandragiri Hills, protected by the monolith Bhagwan Bahubali, and home to over 2,300 years of Jain heritage, is a veritable picture postcard of our history and heritage spanning the centuries. In the town of Shravanabelagola, stands a colossal rock-cut statue of Lord Gommateshwar Shri Bahubali.

Allround Scaffolding Structure behind Bahubali for Mahabhisheka

The main Structure for Mahamastakabhisheka is constructed just behind Lord Bahubali on top of Vindhyagiri Hill. The main Scaffolding structures are used by devotees/Pilgrims for Mahabhisheka. The Approx. 400 Sq. Mtr area considered for construction of Scaffolding structure with two platform at shoulder level and Head level. The Shoulder levels have connected with two cantilever left and right side of Statue to make Mahabhisheka from both the sides. The Head levels have cantilever just above the head levels to Mahabhisheka from head levels. Maximum number of devotees/Pilgrims have made Mahabhisheka from Head level. Design of heavy duty cantilever has been considered to bear heavy load during Mahabhisheka. The existing floor area available double story monolithic structure supported with stone Beam, and slab resting on column. The bottom main existing monolithic structure is also supported with scaffolding to provide additional stability of the existing structure during Mahabhisheka. The total height of Scaffold Structure is Approx. 21.2 mtr from Ground level. It was unsupported with existing structure.

Façade of main structure made out of Aluminium with beautiful symbols of with different colours increase beauty of statue.

The main structure behind statue is well design to bear load bearing capacity of umbrella resting on the top of scaffold, devotees/Pilgrims and other live and dead weight coming on structure. Additional load against horizontal force and wind force considered in design.

Lift: Layher Scaffolding is used for construction of lift for devotees/Pilgrims to reach up to top shoulder and head level. Additional scaffold structure is constructed for support of two lift, thanks to Allround Scaffold for supporting lift against wind force and horizontal force coming on structure at top of the hill. The capacity of lift is 1 tons. Which are used to transport materials used for Mahabhisheka and devotees/Pilgrims up to top of Head levels.

Stair Tower 500: The main structure connected with two number of 16-standard/leg stair towers 500 for access to main scaffold structure for Mahabhisheka. The Width of both the stair tower was 1.57 mtr with landing at every 2.0 mtr height with proper fall preventing systems. One stair tower is used for entrance and another one for exit devotees/Pilgrims during Mahabhisheka. The Load bearing capacity of Stair tower is also designed to bear 5 KN/m².

Event Stage/Deck (Event Platform)

Event deck is used for construction of Platform at shoulder level and Head level. It has been well designed to bear are designed to bear 5 KN/m² for devotees/Pilgrims and storage of materials for Mahabhisheka. The special design of cantilever on both the levels are able to bear more than 5 KN/m². The substructure of the Layher Event systems is created from Layher Allround scaffolding. Event transom of aluminium section with connecting wedge heads of galvanised steel holds the event decks. Clamping lock of spring steel connects the Event deck to the Event transom and acts as a lock against lift-off. All safety measures are considered for fall protection of devotees/Pilgrims during Mahabhisheka. Thanks to the structure designed for heavy load bearing capacity and successfully supported against heavy crowed gathered during Mahabhisheka – 2018.

The Approx Area cover for Mahabhisheka was 2660 Square meter. The Entire area was divided into three part I.e. backside of statue approx. 360 Square meter, VIP Gallery: Approx 650 Square meter and infront of statue: 1650 Square meter. The Layher Event system is a construction kit which you can use to erect a wide variety of stages and stands. Event deck is available in different sizes which can help to fulfil requirement.

The width of the stage decks (in cm) is a practical distinguishing feature and the basis for identification of the modules. The Event decks up to 2.07 m in length are designed for a load of 7.5 kN/m². The Event deck 2.57 m without transom support can bear 5 kN/m². The removable Plastic corners ensure that the vertical tubes can pass through. The coated plywood board is braced with aluminium rungs. n

Authored by

Mithilesh Kumar Director Layher Scaffolding Systems Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)