The Robust Factors

By Staff Report | October 23, 2024 6:19 pm SHARE

Insights from industry leaders on the technological advancements and innovative practices essential for enhancing the resilience of construction projects nationwide.

Any country’s economic growth relies heavily on the development of its infrastructure, and India is no exception. This essential foundation aims to create livable, climate-resilient, and inclusive cities that will improve quality of life and spur economic growth. The government has recognised this need, channelling a substantial 3.3 percent of the GDP into the infrastructure sector for the fiscal year 2024. From highways and railways to smart cities and sustainable buildings, the landscape is evolving to meet modern demands.

To spearhead this transformation, the Government of India has initiated several critical infrastructure projects, such as the Power for All initiative, the Smart Cities Mission, the National Infrastructure Pipeline (NIP), and the Swachh Bharat Mission, aiming to build world-class infrastructure. These projects are vital for boosting economic growth, creating jobs, and improving the quality of life for millions of citizens. However, this surge in activity also brings challenges related to efficiency, safety, and sustainability. As the industry navigates these complexities, focusing on modern techniques, innovative technologies, and sustainable practices has become essential.

In this context, the recent live procurement forum hosted by B2B Purchase, “The Robust Factors for Construction and Infrastructure Projects,” aimed to spotlight the technological advancements, durable materials, and innovative solutions shaping the future of infrastructure resilience. Below are key insights shared by the webinar panellists.

Strategic planning for smart cities and infrastructure development

In the wake of rapid urbanisation, India’s infrastructure sector increasingly focuses on developing smart cities prioritising sustainability and livability. Strategic planning is essential to ensure that these urban environments can accommodate growing populations while maintaining high standards of quality and efficiency. Companies like REPL oversee planning and infrastructure advisory services, providing critical insights and solutions for urban development.

Prabhakar Kumar, Head of urban sector at Rudrabhishek Enterprises Pvt Ltd (REPL) and an expert in planning and advisory services, highlights REPL’s significant role in smart city initiatives. “Our approach emphasises public participation and strategic planning to transform urban spaces into livable, sustainable environments,” he states. REPL’s work on detailed project reports and master plans underscores the importance of integrating smart technologies and sustainable methodologies in urban planning.

However, challenges remain, particularly in retrofitting existing urban areas and managing infrastructure under capacity strain. Kumar notes that REPL has implemented intelligent traffic management systems to enhance transportation efficiency and support economic growth. By leveraging technology and public participation, REPL aims to create urban spaces that foster connectivity and economic development. Strategic planning is vital for successfully developing India’s smart cities and infrastructure projects. By prioritising sustainability, public involvement, and technology integration, the industry can build resilient urban environments that meet the needs of future generations.

The essential role of scaffolding in construction safety

Pankaj S Sharma, CEO of AVANZA Steel Pvt Ltd, highlighted an often-overlooked aspect of construction: scaffolding. He described it as a critical catalyst for infrastructure development, underpinning railways, road construction, and rural development projects. “Although scaffolding may seem like a minor component, it is foundational to safety and efficiency in construction,” Sharma noted. Traditionally, bamboo has been the material of choice for scaffolding, but there has been a significant shift towards steel scaffolding in recent years, enhancing safety and durability.

Sharma raised important concerns regarding the safety standards surrounding scaffolding in India, pointing out that outdated British safety standards still prevail. “We need robust safety standards aligned with the Indian Bureau of Standards (BIS) to prevent accidents on construction sites,” he urged. Technological advancements, such as sensors to monitor load capacity, have begun to improve safety measures. Still, he highlighted that only about 20 percent of scaffolding in India is currently made from steel, despite its numerous advantages.

Due to its reusability, steel scaffolding is more sustainable and cost-effective. Sharma advocated for regulatory changes to enforce its use, particularly for taller buildings, while emphasising the need for education and support for contractors transitioning from bamboo to steel. By doing so, the construction industry can enhance safety and sustainability.

Embracing automation and sustainability in material handling

The construction industry increasingly recognises the importance of automation and sustainability in material handling processes. As projects scale in size and complexity, integrating modern technologies is essential for enhancing efficiency and ensuring safety. Electric hoists, EOT cranes, and ergonomic handling solutions are critical in facilitating the seamless movement of materials on construction sites.

Debi Prasad Padhy, Vice President of Sales at Bajaj Indef, emphasises the company’s commitment to innovation and sustainability in material handling. “Our products are designed with resilience in mind, ensuring that they not only meet current demands but also adapt to future challenges,” he explains. Bajaj Indef’s focus on automation and IoT integration supports data-driven decision-making, enhancing safety and productivity on construction sites.

The company’s extensive product range, which includes advanced hoists and cranes, is tailored to meet rigorous standards and support sustainable practices. The integration of smart technologies not only improves operational efficiency but also fosters a culture of safety and sustainability within the industry.

As the construction sector grows, the importance of adopting automated and sustainable practices in material handling cannot be overstated. Companies that embrace these advancements will be better positioned to meet the market’s demands while contributing to environmental sustainability.

The Role of steel Steel-cutting Technologies in Infrastructure Projects

As construction projects in India become increasingly complex, the importance of advanced steel-cutting technologies cannot be overstated. Efficient cutting systems are essential for processing steel in various infrastructure projects, such as airports, bridges, and buildings. Integrating technologies like CNC machines with plasma and oxyfuel cutting capabilities streamlines production, reduces handling time, and enhances precision.

Messer Cutting Systems, a pioneer in thermal cutting, has recognised the critical need for innovation in this area. According to Karthik Murugesan, Manager of Product Management, Messer Cutting Systems, the company’s advancements in steel processing technologies are designed to support the ongoing infrastructure boom in India. “Our latest CNC machines feature user-friendly controls and IoT compatibility, which significantly improve productivity and minimise manual intervention,” he explains.

Incorporating smart software solutions for digitisation allows for seamless integration with enterprise resource planning (ERP) systems, enhancing overall operational efficiency. As the demand for quick, durable, and efficient structures rises, the steel industry must leverage these technologies to maintain competitiveness. Advanced cutting technologies are essential for meeting the high demands of India’s infrastructure projects. By embracing innovation, the industry can ensure its operations’ precision, efficiency, and sustainability.

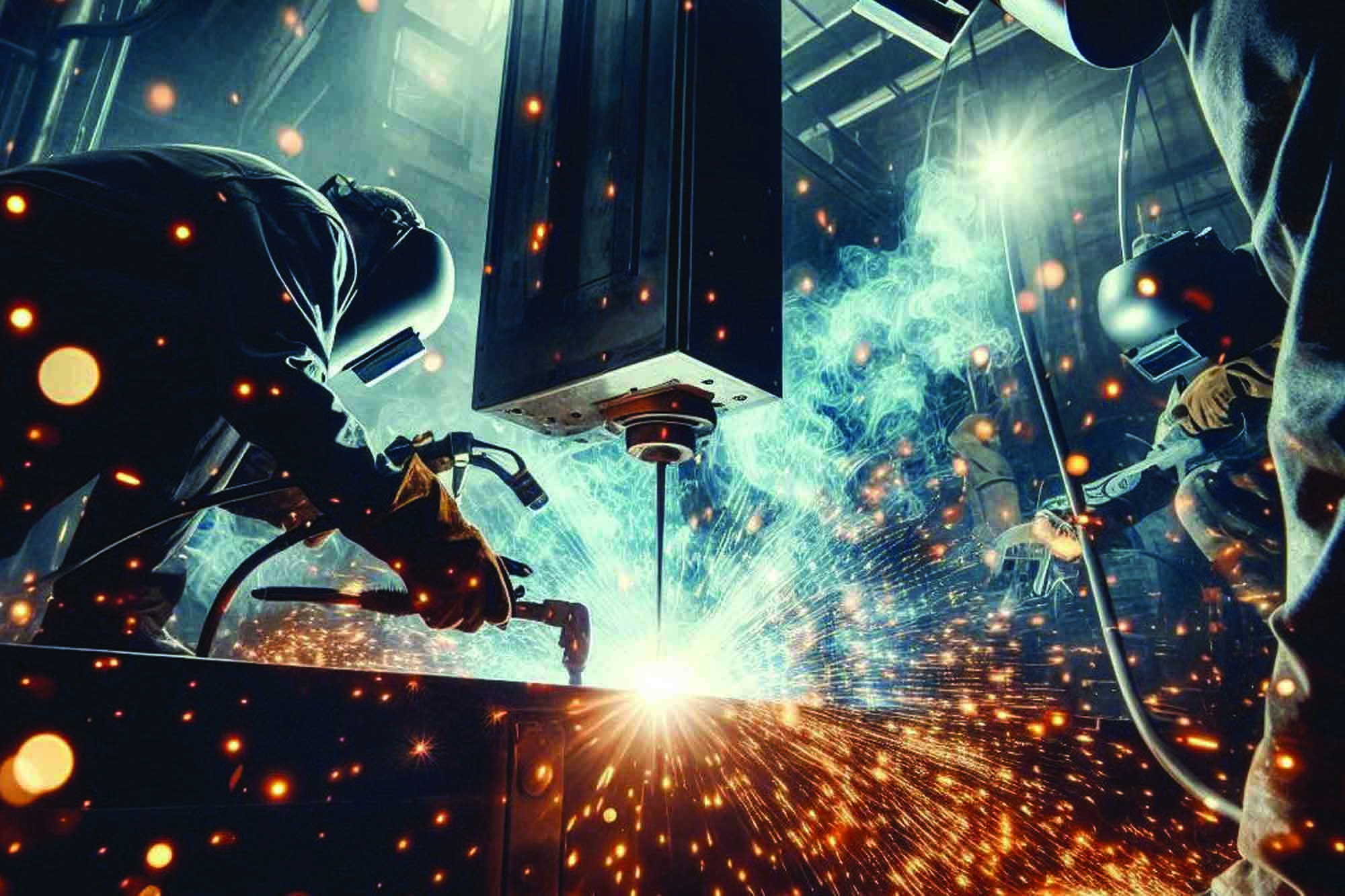

Efficiency and productivity in modern welding processes

Nimesh S. Chinoy, Marketing Director, Electronics Devices Worldwide Pvt Ltd, a prominent voice in the welding sector, outlined the evolving landscape of welding processes in construction. He noted a marked shift from traditional arc welding methods to more efficient techniques that are increasingly necessary in the age of rapid construction and modular building designs. As Chinoy articulated, “The productivity advantages of modern welding methods are undeniable. For instance, while traditional arc welding has a deposit rate of only 0.4 to 5.5 kg/hour, MIG welding can achieve up to 12 kg/hour, and flux-cored arc welding can even reach 16 kg/hour.”

This productivity boost is critical as construction demands accelerate, especially with the rise of pre-engineered and modular buildings that require swift on-site assembly. He highlighted that mechanising the welding process—through tools like trolleys and advanced equipment—enhances productivity while reducing material waste. For example, by adopting thin wire submerged arc welding, productivity can increase by up to 7.5 times for heavy fabrication tasks.

Moreover, Chinoy pointed out the significant benefits of transitioning to inverter-based power sources, which have been shown to improve energy efficiency and output in welding operations. “To fully harness the potential of MIG and flux-cored welding, it’s essential to invest in retraining our workforce. This transition allows welders to operate at speeds 2.5 times faster, leading to greater metal recovery and minimising losses,” he stated. The commitment to upgrading welding techniques is not merely about efficiency but also enhancing the overall quality of construction projects.

Fostering resilience in India’s construction and infrastructure sector

India’s construction and infrastructure sector is at a critical juncture, with immense opportunities for growth and development. As the industry faces efficiency, safety, and sustainability challenges, embracing modern techniques and technologies is essential for fostering resilience.

From the adoption of advanced welding and cutting technologies to the critical role of scaffolding and material handling solutions, each aspect of the industry must evolve to meet the demands of a rapidly changing environment. Additionally, strategic planning for smart cities will ensure that urban development aligns with sustainability goals and enhances quality of life.

The collective insights of industry leaders underscore the importance of collaboration, innovation, and a commitment to sustainable practices. As India continues to build its infrastructure, the focus must remain on creating robust systems that can withstand the test of time, ultimately benefiting society. By prioritising resilience and adaptability, the construction and infrastructure sector can thrive in the face of future challenges.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)