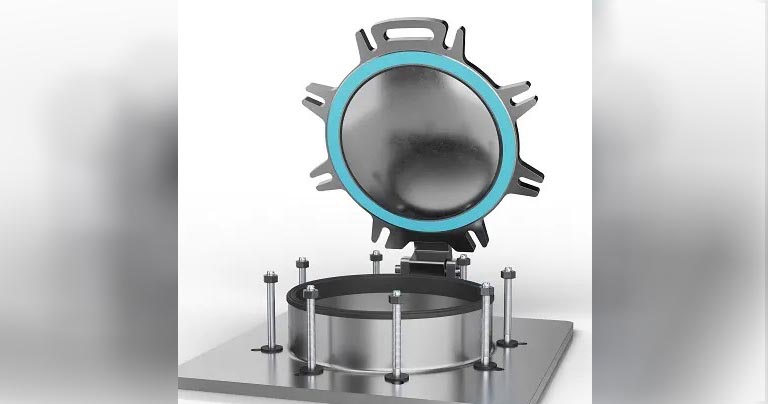

Trelleborg launch new Turcon® Tran-SECURE™ PTFE manway lid gasket

By Edit Team | December 15, 2022 3:36 pm SHARE

The new manway lid gasket offers customers an enhanced sealing solution with an improved design featuring Trelleborg’s proprietary, high-performance Turcon® PTFE material. The glass-reinforced polytetrafluoroethylene (PTFE) delivers improved compressive and tensile strength while minimising creep relaxation to ensure a tight seal over an extended period of time. The chevron-based design of the gasket uses the PTFE’s inherent elasticity to create its own sealing pressure, which helps it resist the deformation common to other manway gasket materials without sacrificing sealing force or surface pressure.

Thijs Menzel, Segment Director, Chemical Transportation, Trelleborg Sealing Solutions, says: “The chemical industry faces many challenges, both in the processing of materials and in the transportation of these materials to customers. According to the Association of American Railroads, the manway is the leading cause of non-accident releases (NARs), meaning it is critical that the industry has a readily available and reliable source for high-quality gaskets.

“For decades, shippers, tank car manufacturers, and railcar repair shops have relied on Trelleborg to provide high-performance seals and repair kits, material testing, and root cause analysis support. To fulfil their need for a single-source supplier for all of their sealing requirements, we developed the new Turcon® PTFE manway lid gasket. “Our materials engineers specially selected the proprietary Turcon® PTFE compound because of its superior sealing qualities when transporting a broad range of chemicals and other liquid commodities.”

For more details visit www.trelleborg.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.