Unlocking Screening Efficiency for Blinding and Wire Breakage Prevention

By Edit Team | July 17, 2023 1:40 pm SHARE

The Self-Cleaning Screen’s unique design distinguishes it from traditional woven wire screen mesh. Its flexible and independently vibrating wires prevent wet material from sticking to the mesh surface, ensuring effective screening.

Screen blinding occurs when wet materials or dust accumulate on the screen surface, leading to fines and dirt particles buildup, eventually covering the entire screening area. The severity of blinding depends on the stickiness of the screened material. Smaller aperture sizes, typically ranging from less than 8mm to 10mm, are more prone to blinding as they allow fines and sticky materials to get trapped and adhere to the screen surface, reducing screening effectiveness. This has been a prevalent issue among our customers in the UAE and Oman.

To address this challenge, Ashar Locker introduced the Poly Ripple Screen, also known as the Self Cleaning screen, which has proven to be a revolutionary breakthrough. This innovative solution successfully resolves the blinding problem by an impressive 95 percent. The Self-Cleaning Screen’s unique design sets it apart from traditional woven wire screen mesh. Its flexible and independently vibrating wires prevent wet material from sticking to the mesh surface, ensuring effective screening. Maintenance: The Unsung Hero in Screen Longevity

To address this challenge, Ashar Locker introduced the Poly Ripple Screen, also known as the Self Cleaning screen, which has proven to be a revolutionary breakthrough. This innovative solution successfully resolves the blinding problem by an impressive 95 percent. The Self-Cleaning Screen’s unique design distinguishes it from traditional woven wire screen mesh. Its flexible and independently vibrating wires prevent wet material from sticking to the mesh surface, ensuring effective screening.

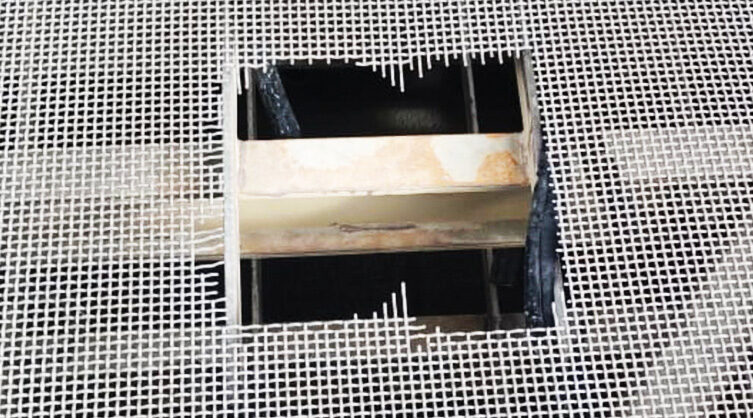

A common grievance voiced by our esteemed customers pertains to wire breakage and premature screen damage. An in-depth analysis has revealed that a major contributing factor to these issues lies in the direct contact between the screen meshes and the stringer bar.

Upon closer examination, we discovered that the metal-to-metal contact between the screen mesh and the stringer bar often results in straight-line cuts on the screens, leading to premature wire breakage. This occurrence directly results from wires within the screen mesh coming into contact.

To mitigate wire breakage caused by damaged rubber capping on the stringer bar, a high-quality rubber cap is imperative. It acts as a protective layer, effectively preventing direct contact and reducing friction between the wires of the screen mesh. Employing durable and resilient rubber binding minimises wire-to-metal contact, decreasing the risk of wire breakage and extending the screen mesh’s lifespan.

Wire breakage issues can be effectively resolved by recommending our esteemed customers invest in high-quality rubber capping from https://asharlocker.com/rubber-capping.html. Superior rubber capping is a protective shield, preventing direct wire-to-wire contact within the screen mesh. This reduction in friction significantly reduces the chances of wire breakage. Embracing durable and reliable rubber capping preserves the screen mesh’s integrity, leading to prolonged longevity and optimal screening performance.

By prioritising maintenance and taking preventive measures such as inspecting for metal-to-metal contact, implementing protective liners, and following a regular maintenance schedule, you can mitigate wire-breaking issues, prevent screen damage, and ensure the longevity of your screening media.

Client Testimony –

Mr. Bohara expressed his satisfaction with Ashar Locker’s Self-Cleaning screen and woven wire screen media, stating that they had the pleasure of utilizing these products for their screening processes. He confidently attested to the exceptional quality offered by Ashar Locker.

Mr. Bohara expressed his satisfaction with Ashar Locker’s Self-Cleaning screen and woven wire screen media, stating that they had the pleasure of utilizing these products for their screening processes. He confidently attested to the exceptional quality offered by Ashar Locker.

We are highly impressed with the superior performance and reliability of Ashar Locker’s screening media, which has exceeded our expectations. The high-quality products have greatly enhanced our screening operations by ensuring durability, efficiency, and optimized performance. Ashar Locker’s exceptional after-sales service has also been a source of great satisfaction, as they have promptly addressed any concerns or inquiries. Furthermore, their competitive pricing has made their screening media solutions a cost-effective choice for our organization. Overall, the combination of outstanding product quality, responsive customer service, and reasonable pricing has established Ashar Locker as a trusted partner in our screening processes. We extend our appreciation to the entire Ashar Locker team for their dedication to delivering top-quality products and innovative solutions.

The article has been authored by Santosh Singh, Business Development – Middle East, Ashar Locker India Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.