We are authentic OEMs, not just integrators

By Admin | August 16, 2022 2:19 pm SHARE

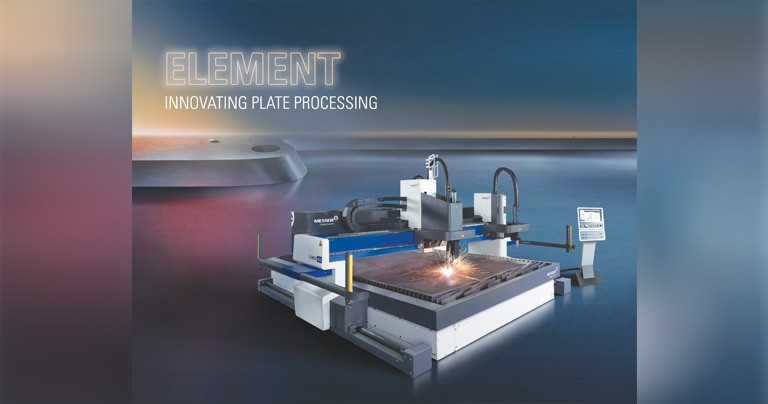

The demand for laser cutting machines has been consistently growing, and we have come up with gantry and unitised laser machines, says Prashant Chaturvedi, GM – Marketing, Messer Cutting Systems.

Messer is a Pioneer in the Thermal Cutting Machine Industry. What is the latest in your offering, and how do you handle the market dynamics?

Yes, Messer is a pioneer in the Thermal Cutting Machine industry. What started as a very humble oxytorch business in 1898 has grown into a multi-billion-dollar business conglomerate worldwide in 123 years. We always strive to be ahead of the market by seeing the world through our customers’ eyes. We balance and master the two worlds of contradictions. This motivates us to remain leaders in any emerging technology in the metalcutting industry. It’s all about blending excellence and innovation in every part of the business. Hence, we are committed to being a pioneer in the future and bringing out the latest in this industry to our customers.

Constant and consistent collaboration with the customers and an evergrowing hunger for excellence ensure that Messer dynamics sync well with the market dynamics. Being a consultant and solution provider for the customer’s complex needs is the hallmark of Messer that no other company can claim today. We nurture value-driven relationships with our customers. Others can copy or snatch the design or technology from us, but not our company’s culture. Our val system is so strong that it enables us to reinvent ourselves constantly to meet the market dynamics with vigour and courage.

The company started with oxyfuel cutting and was the first to launch plasma cutting machines. It has the best machines in these ranges in both oxyfuel and plasma cutting.

The demand for laser cutting machines has been consistently growing in the last few years, and we have developed gantry and unitised laser machines. That made us the only international company to have complete thermal cutting solutions with all three technologies-Oxyfuel, Plasma and Laser.

We have also diversified into valueadded products like the Plate Processing Machine, where we offer the cutting process combined with machining processes like drilling, milling, tapping, etc., to make a complete component on the machine.

What are the significant expectations of clients from the players in your industry? How do you meet their

expectations?

Customers universally expect the highest product quality, fastest delivery, best service, and lowest price. In the prevailing highly volatile and uncertain market and economic scenario, the customer’s preferences and priorities change rapidly. We must be fully prepared to meet the challenges headon. As explained previously, our close collaboration and rapport with the customers make it simple for us to foresee and prepare to face it.

In our country, cost plays a significant role in decisionmaking. But in our experience, customers are ready to pay the premium if you justify your cost with the value you offer. We have also been successful in acquiring a decent market

share because the running cost of our products is lower over their life cycle.

Most competitors try to innovate their products and technology, but their service networks are not robust. In particular, most of the imported machines have barely or no after-sales support. We have a significant edge over the competition with a well-positioned and well-trained country-wide service network.

Similarly, most clients are looking to increase the productivity of their plant while keeping the cost to a bare minimum. Apart from our superior product quality, our after-sales support, including visual, virtual, and IoT-based solutions, plays a vital role in achieving higher productivity, which, as mentioned above, most players currently lack.

How did the company become a global supplier of cutting-edge solutions for the metalworking industry and a technology leader in manufacturing CNC Plasma and Laser Cutting machines in India?

We believe in creating backend support. It has always been a challenge to be continuously successful worldwide as a global solution provider. Our focus has been on creating the backend support system and constantly upgrading it, which includes R&D, Application Engineering, Product Management, and Solutions Management.

We have a dedicated team in our R&D working on Industry 4.0 and IoT solutions that helps us to stay ahead of the curve. We are the technology and market leader in plasma and oxyfuel cutting machines worldwide. Our machine quality is the same whether we produce in India, America, or China. We do not make machines without the proper infrastructure to produce quality products.

But we do not claim ourselves to be a technology leader in laser cutting machines, though we were the pioneers there

also-Messer was the first company to make a laser cutting machine way back in 1970. Since we felt that the world was still not ready for that, we focused on plasma and Oxyfuel technology.

We decided to enter the laser business in 2011, and now we have laser products that can compete with the current industry leaders.

What are the various features and benefits of your products that your clients can reap? Tell us concerning your Oxyfuel, Plasma, and Laser Cutting machines.

Our machine comes with our aggregates, which means, other than the Laser and Plasma resonators and the motors, all the aggregates on our machine are our products. That makes us the authentic OEM – not integrators.

Regarding Plasma/Oxyfuel, we have many technological advantages compared to our competitors, and our machines are highly productive, more reliable, and cost-effective.

Apart from this, we have strong application experience in sectors like windmills, yellow goods, shipbuilding, transmission towers, beveling, and many others. Our machines will produce quality and accurate parts at a minimum cost. This makes us provide optimum solutions to our clients, which can be more productive.

As far as laser machines are concerned, our laser products are offered in different formats, like unitised and gantry type machines, along with bevel solutions depending on customer needs.

We also produce laser machines in combination with plasma processes. And, our laser machines are cost-effective compared to the industry leaders, with comparable features and benefits. They can be integrated with automated solutions like auto sheet loading, unloading, and sorting and storing finished parts.

What is the future roadmap for Messer Cutting Systems? How is the company gearing up for the same?

We will continue to strive to:

• Stay as the technology leader and market leader in plasma and oxyfuel cutting.

• We will continue to be the market leader in the plasma and oxyfuel cutting business.

• We continuously increase our market share.

• to be a significant player in the laser business as well.

• To be the best solution provider for automation and IoT in the thermal cutting industry.

• To constantly innovate and upgrade products that fill customers’ needs is our clear guiding philosophy, giving the best support to clients at the minimum possible cost to make them more competitive.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.