Why Environ Energy Efficient Aerators (EEEA) for effluent/sewage treatment plants?

By Staff Report | October 25, 2024 8:21 pm SHARE

Environ Energy Efficient Aerators offer an innovative approach to aeration, combining energy efficiency with adequate mixing and oxygen transfer. With a unique dual impeller design, they promise reliable operation and reduced energy costs, making them an ideal choice for modern aeration systems.

Environ Energy Efficient Aerators are meticulously designed and manufactured, considering the key factors that experts, consultants, EHS managers, and industry leaders prioritise when evaluating aeration systems.

These aerators provide sufficient oxygen transfer to promote biological treatment, which is the fundamental requirement of any aeration system. They also ensure effective mixing to maintain the homogeneity of mixed liquor-suspended solids and prevent solids from settling. This aspect is critical in selecting an aeration system, as the aerator must transfer oxygen and function efficiently as a mixer. Improper mixing in the aeration tank can lead to sludge settling at the tank floor, which creates septic conditions and reduces dissolved oxygen (D.O.) levels, sometimes to zero. Environ Aerators are equipped with dual impellers: one at the top for oxygen transfer and another at the bottom for rigorous mixing, ensuring no sludge settlement.

These aerators are designed to adapt to varying process conditions, maximising energy efficiency while providing reliable service with minimal maintenance and downtime without sacrificing oxygen transfer capability.

The aerators are built with a unique design that minimises maintenance and downtime:

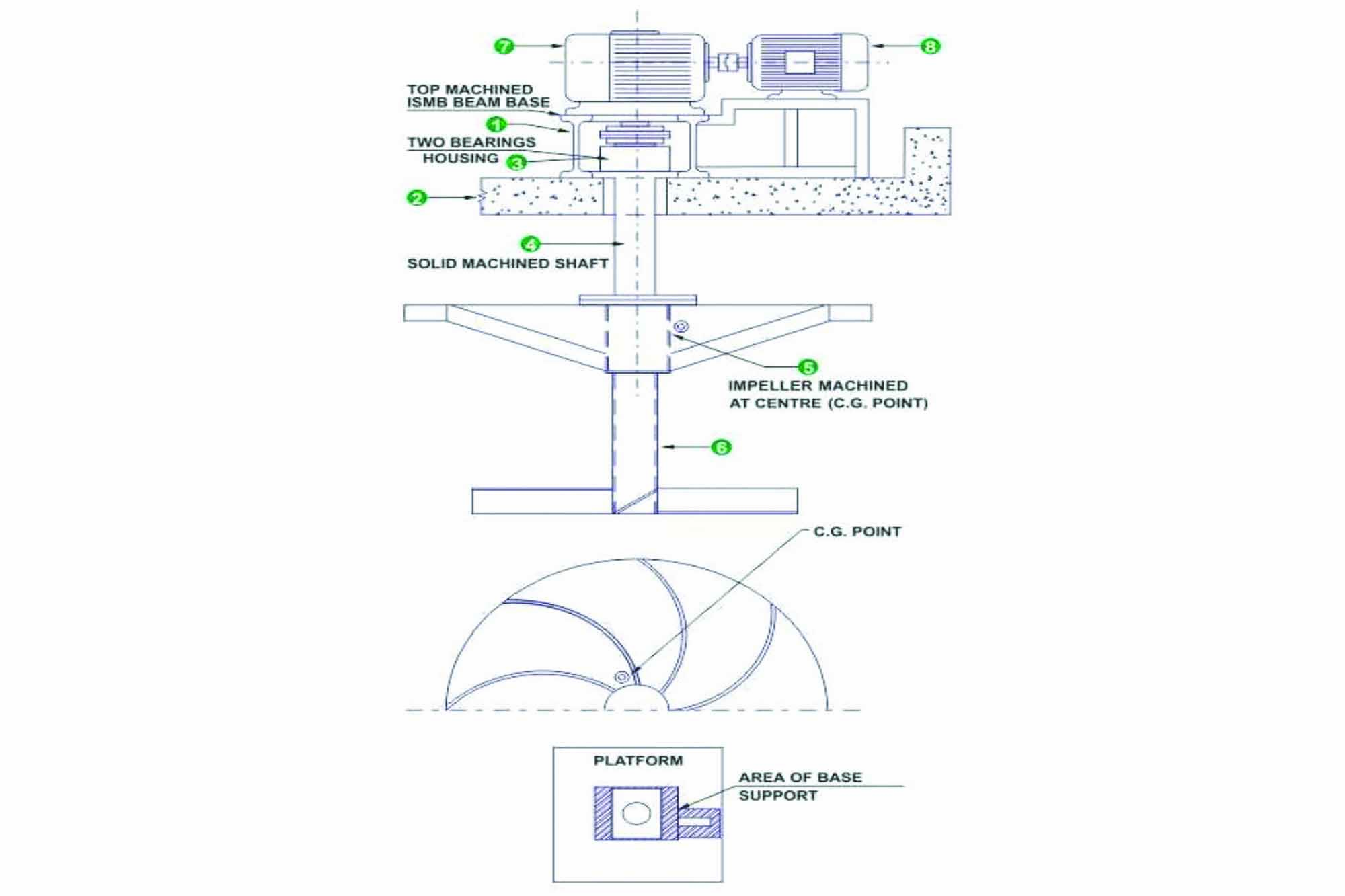

- For 5HP to 15HP ratings, a fabricated and machined base frame is used, and for 20HP and above, a heavy ISMB beam base is provided. This reduces vibrations, and the base is machined on the top surface to extend the life of the ENVIRON energy-efficient surface aerator gearbox.

- Additional bearing support is provided to the aerator shaft to prevent the transfer of unbalanced cantilevered loads to the gearbox output shaft.

- The aerators feature a fully machined MS solid shaft capable of handling torsional loads.

- The impeller is designed as a single-shrouded pump impeller, maximising oxygen transfer and mixing efficiency. It is also machined at the centre to ensure concentric running.

- The next-generation Environ Energy Efficient Aerator (EEEA) comes with an additional impeller at the bottom, enabling better mixing at the aeration tank floor, even in tanks with a water depth of up to 6 meters. This rigorous mixing increases oxygen solubility, enhancing the impeller’s oxygen transfer efficiency. As a result, less horsepower is required to achieve more oxygen transfer, leading to energy savings.

Environ Energy Efficient Aerators offer superior performance and take on the challenge of reducing energy consumption by 20 to 70 percent in any aeration system, with guaranteed results. The system’s compact design, accommodating water depths of up to 6 meters, also reduces the required area, lowering civil construction costs and making the solution highly economical.

Each & every aerator runs for 2 hours in the testing facility to check its manufacturing defects, if any.

Contact:

Jayraj C Thakore (Managing Director)

Environ Engineering Compnay

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)