Why OEMs need Service Life-cycle Management

By Edit Team | March 25, 2015 12:46 pm SHARE

According to Quest Informatics, for OEMs, on an average after-sales service constitutes 34 per cent of their total revenue and it generates an astounding 25 to 55 per cent of profit. The parts business account for 10 to 15 per cent of sales and averages 25 to 50 per cent of profits. Additionally, profit margins on service contracts are around 25 to 50 per cent, with strong impact on customer loyalty. Warranty costs can impact up to 3 per cent (or more) of yearly net revenues. So, it is evident that the success or the failure of an OEM is dependent on its quality of after-sales service delivery. OEMs are dependent on service because of various reasons, including the following:

• Stiff competition has reduced the margins from new product sale

• Equipment or product buyers are looking for performance commitments than just owning them.

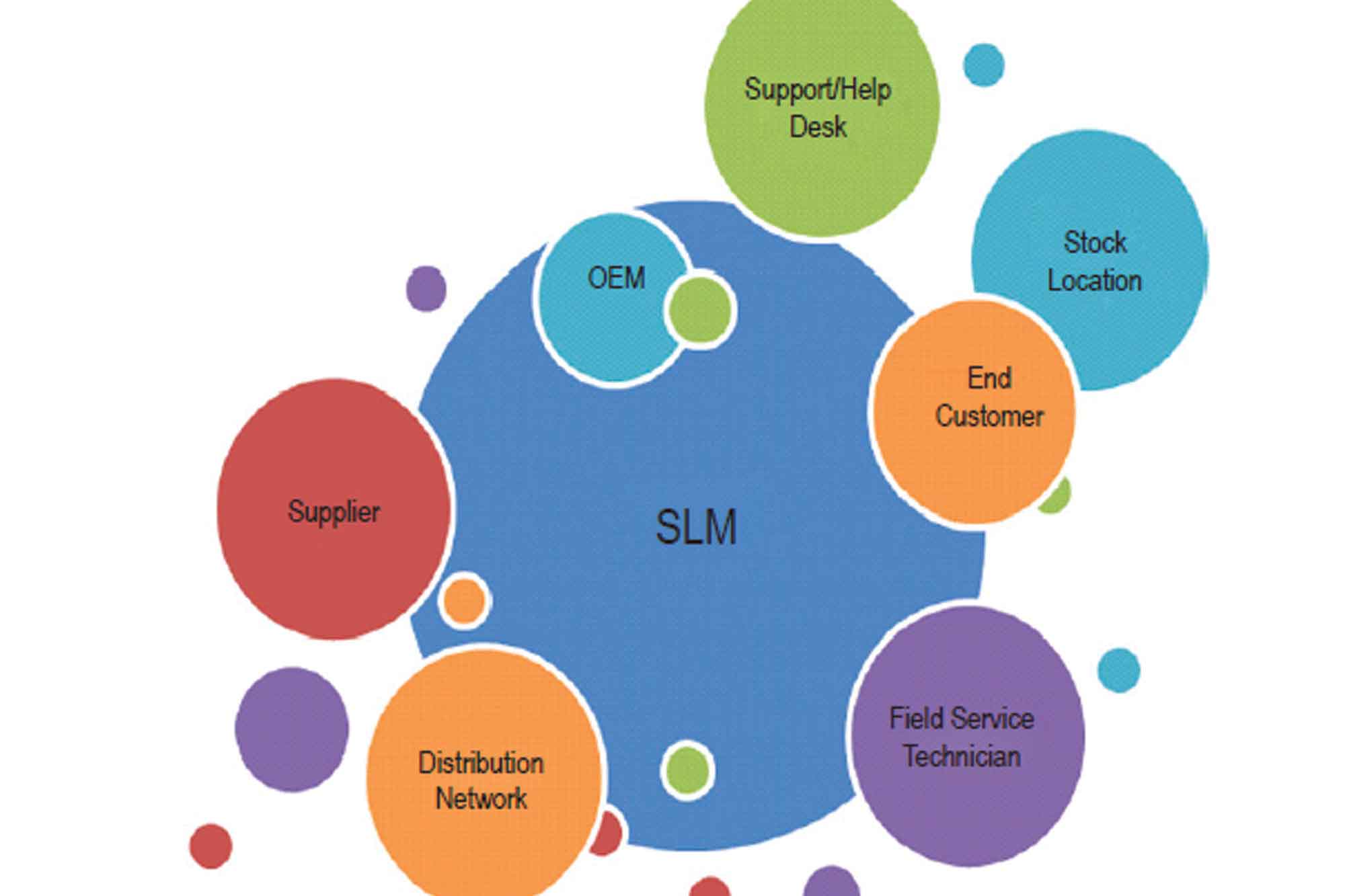

To ensure efficient service delivery, OEMs have brought all service processes under one roof called Service Life-cycle Management (SLM).

What is SLM?

Service Life-cycle Management (SLM) is the profit-driven optimisation of the gamut of processes employed by manufacturers and their service partners ensuring the products perform as promised. SLM is a key value differentiator in durable goods, product, or equipment industry.

SLM includes following service processes:

• Complaint/call registration and management

• Technical support

• Spare parts management

• Warranty management

• Knowledge base and feedback management

• Proactive service suggestion based on historical data

• Right resource allocation

• Returns management

• Resource travel management

• Escalation

• Workshop management

• Reports and analytics like KPI, ageing analysis, mean time to respond, mean resolution time, First Contact Resolution (FCR) etc.

For effective SLM operations, OEMs must deploy comprehensive IT and process systems that facilitate seamless integration of activities across various actors at different stages. World-class SLM solutions require integration of explicit and implicit knowledge management routines, effective allocation and comprehensive service management. Many SLM solutions available in the market are point solutions, that they have a deep dive of a particular stage or group of stages. They can’t smoothly integrate with other enterprise solutions including parts, sales, and vendor management. OEMs deploying these solutions may need to invest in high customisation and API development.

Quest Informatics is an aftermarket specialist company, which has developed a comprehensive collaborative SLM solution. Quest SLM solution is based on industry best-practices across different verticals. Quest SLM development is a culmination of its more than two decades of solution development expertise for Fortune 500 companies across the world. Quest SLM is a highly scalable, outsourcing enabling, enterprise class solution that can be deployed in couple of weeks.

Apart from SLM, Quest Informatics, has developed and deployed basket of aftermarket products including Aftermarket ERP, Field Service Management (FSM), Support Desk System (SDS), Remanufacturing Management (REMAN with detailed core and periphery estimations) and Rental Management System (RMS). These products are available for in-situ license purchase, Cloud subscription, Outcome based managed service and other models.

Quest also provides aftermarket services like maintenance and integration of illustrated parts catalogues, parts planning, parts information management, 3D animated technical publication (service/owners/repair manuals), CAD services, parts helpdesk, service desk, product helpdesk.

Quest does aftermarket consulting projects on areas like dealer audit, process improvement, revenue leakages, operations improvement, warranty costs management and parts and service benchmarking.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.