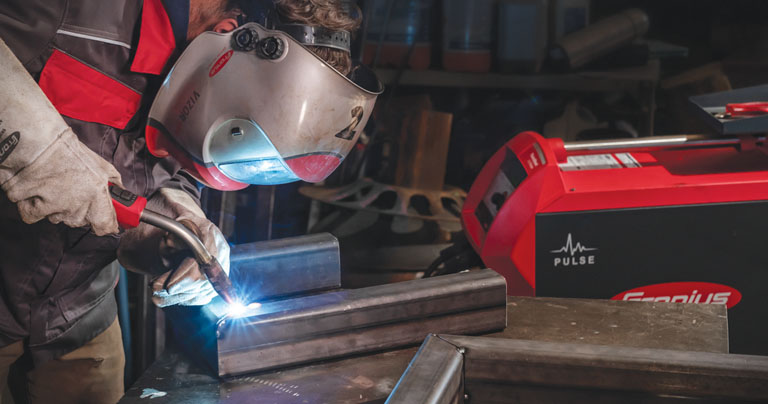

ALL-ROUNDER: faster welding speeds and less rework

By Admin | August 13, 2022 11:15 am SHARE

The extension to the Pulse function now makes our welding machines real all-rounders.

Fronius offers this with the TransSteel device series, in which the pulse function has been expanded. The pulsed arc enables more speed with greater material thicknesses. In addition, the rework is reduced because the pulsed arc results in minimal welding spatter.

The pulse mode allows the difficult-to-be-controlled and spatter-prone transitional arc to be avoided. The spatter

formation is thus reduced, leading to up to 70 per cent less rework. In addition, the pulsed arc achieves speeds up to 30 per cent faster. These advantages are offered according to factory specifications and are now also in the Fronius TransSteel 3000 compact and the TransSteel 4000 and 5000.

Stable with a pulse

The TransSteel devices were specially developed for use with steel. The extension to the Pulse function now makes the welding machines real all-rounders because many functions support the welder with different applications, according to the company. With the help of this tool, even spot welds can be set using the spotting function – ideal for tacking workpieces.

Interval welding not only ensures a rippled seam appearance. The lower heat input also reduces the possibility of material warpage for thin sheets. Unique curves provide the user with the ideal arc characteristics. It goes on to say that “steel” ‘s universal characteristics are particularly suitable for simple and fast welding applications.

“Steel Root” was developed for root welding and provided a soft and stable short arc for good gap bridging ability with wide gaps.

On the other hand, the “Steel Dynamic” welding program has a particularly hard and concentrated arc equipped and

achieves such high welding speeds and deep penetration. Minimal spatter and deeper penetration offer the TransSteel Pulse devices with “Pulse Controlled Spray Arc,” which are the ideal settings. With the “SynchroPuls”, the changes in welding power are up to five Hertz between two working points. The change between high and low currents makes welding easier in an ascending position. So, one can achieve pronounced seam ripple formation in aluminium alloys.

Three performance classes—one solution: As one emphasises, the intuitive operating concept of the TransSteel enables the device to be started immediately without prior knowledge. All the necessary parameters can be set on the front of the device. A simple option for documenting the welding data rounds off the device concept. A USB stick can be connected to the back of the power source to store all critical data – including time and device-related data, as well as the parameters used, such as current, voltage, and wire feed.

The company has recently equipped three devices with the pulse function: The TransSteel 3000 compact Pulse is a

multi-process device that masters all three welding processes (GMAW, GTAW, and MMAW) at the same high level. The compact device is ideal for a wide range of welding tasks on ferrous and non-ferrous alloys on the construction site, in the workshop or for repair work. Thus, this device can also be perfectly suitable for SME’s.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)