Allround shoring TG 60 ideal for construction work

By Edit Team | March 13, 2024 12:57 pm SHARE

Discover how Layher’s innovative concepts and global reach are redefining the construction landscapes and offering unparalleled versatility across industries globally.

Layher, a renowned German company, is a leading producer of top-notch scaffolding systems. Since its inception, Layher has consistently injected crucial innovation into scaffolding construction, significantly shaping industry developments with its groundbreaking ideas. With a global footprint, Layher boasts over 40 sales subsidiaries. Its products find application across various industries, including construction, cement plants, chemical plants, power plants, shipyards, and offshore operations.

More possibilities – Layher products and services

Layher’s present product characteristics and services help customers achieve long-term success and increase the profitability of their companies. Layher Allround Scaffolding has been established as a synonym for modular scaffolds on the market. Allround Scaffolding offers unsurpassed versatility for construction sites, the chemical industry, power plants, aircraft, shipyards, the event sector, theatres, and arenas.

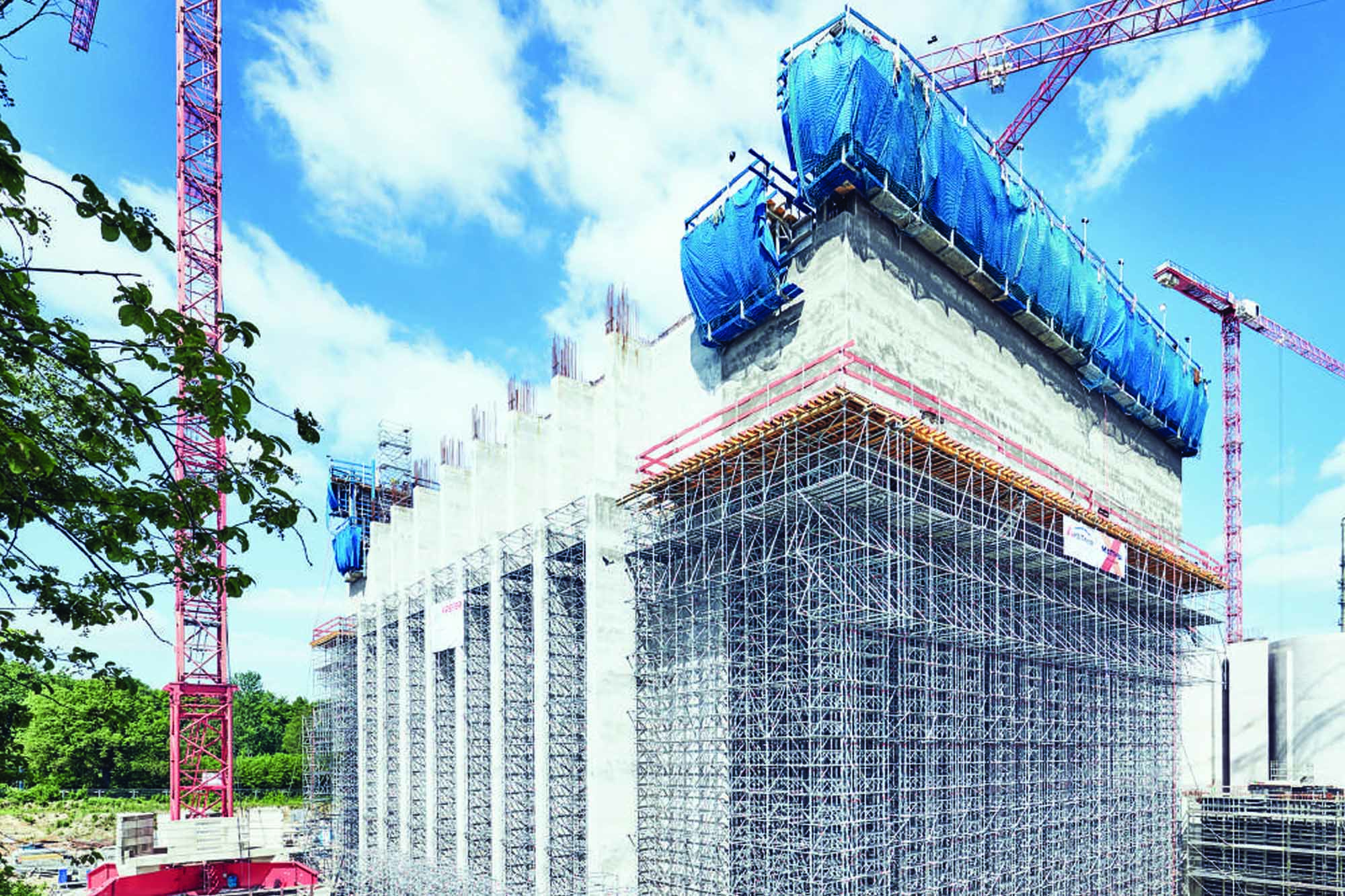

Application of Layher Allround Shoring TG 60 with access

Layher Allround shoring TG 60, (The False work frame – even more possibilities) Allround scaffolding uses a simple, unique, and bolt-free connection technology. Sliding the wedge head over the rosette and inserting the wedge into the opening immediately secures the component. There is still sufficient play to secure the other end of the ledger. A hammer blow to the wedge transforms the loose connection into a superbly strong, structurally rigid one. The face of the wedge head is now precisely positioned against the standard.

During the upgrading of the airport’s terminal and its access roads, flexible support was needed for concreting work on a roadway. Layher has provided the solution for the building company, which is flexible Allround Shoring TG 60 from Layher. This allowed the erectors to provide without any problems a vehicle access with a clear width of more than four metres, and also to match the shoring structure precisely to the existing binding beams, despite restricted spaces – and all that in a completely safe way thanks to Allround side protection.

To maintain its high-quality standards in the future and to ensure the continued functioning of its infrastructure, the airport is regularly upgraded and expanded. Refurbishing the access roads for departures and arrivals are also some of its current construction projects. In this case, the concreting work for a roadway proved to be a particular challenge for the construction company. The necessary shoring firstly had to include vehicle access with a clear width of more than four metres, and secondly adapt optimally to the shape of the already existing binding beams – and all this both quickly and efficiently to keep within a tight schedule.

After a very positive previous experience, the project engineers consciously chose Allround Shoring TG 60 from Layher for this project too. The modular-designed and hence extremely flexible system consists of high-strength shoring frames that combine with standard parts from the proven Allround range, such as ledgers and diagonal braces, to create shoring towers with bay lengths between 1.09 and 3.07 metres. That gives construction companies a huge benefit. Firstly, rapid assembly considerably improves efficiency at construction sites. This is assured by the reduced number of components in the prefabricated shoring frame in comparison with individual parts, by the low component weight of max. 18 kilogrammes, and by bolt-free wedge-head connectors – but also by optimum use of material, since the TG 60 system can be flexibly adapted to the load in question and to the predefined geometry. Assembly time is minimised.

On the other hand, every requirement on a construction site can be economically implemented using the comprehensive range of Allround components. It doesn’t matter if it’s for geometry adaptations or for adding working levels and stairway towers: compatibility with the Allround system and its wedge-head connection ensures highly flexible shoring construction. In this project, the scaffolding erectors from Marti were not only able to optimally match the shoring structure, about seven metres high, to the shape of the already present binding beams, but also to provide the required vehicle access in an economical way using a lattice made from Allround Shoring Frames TG 60, instead of steel beams or lattice beams. The loads were transmitted directly into the adjacent shoring towers. Adjustment at the edge area was achieved in a material-saving way using a bracket – likewise using Allround components.

During the assembly of the structure of some 250 square metres in size, Allround Shoring TG 60 proved to be not only very fast to build but also very safe. Due to the use of Allround standard material, time-consuming bracing using tubes and couplers, or measurement of individual towers to ensure they meet planning requirements, for example, was no longer needed. After the assembly of a single tower, the distance to the next tower results automatically from the positioning of Allround ledgers on the ground. Rectangularity is also assured. The safe assembly sequence for Allround Shoring TG 60 also provides scaffolding erectors with all-around side protection, even without additional components. This allows valid safety regulations to be met in full during shoring construction.

By this method, the scaffolding erectors created, with this material-saving and flexible support, and in a very short time, the optimum conditions for concreting the roadway for access to Switzerland’s largest airport.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.