Aluminium extrusions – Taking defence manufacturing sector to the next level

By Edit Team | April 30, 2021 2:31 pm SHARE

In opening up the space for private sector participation in the indigenous manufacturing of defence equipment, India has simplified procedures that promote the procurement of design, development, and manufacturing of capital equipment in the country.

By providing an impetus and a nudge to the private defence business, Government of India has notified a model of creating long-term strategic partnerships that offer opportunities for more significant private participation in the defence sector.

The government has also formulated a policy for the indigenisation of components and spares used across different defence platforms. This policy, paving the way for more extensive domestic private manufacturing in the defence sector, was notified in March 2019 to create an industry ecosystem that can indigenise the imported components, including alloys, unique materials, and sub-assemblies for defence equipment manufactured in India.

Role of aluminium extrusions

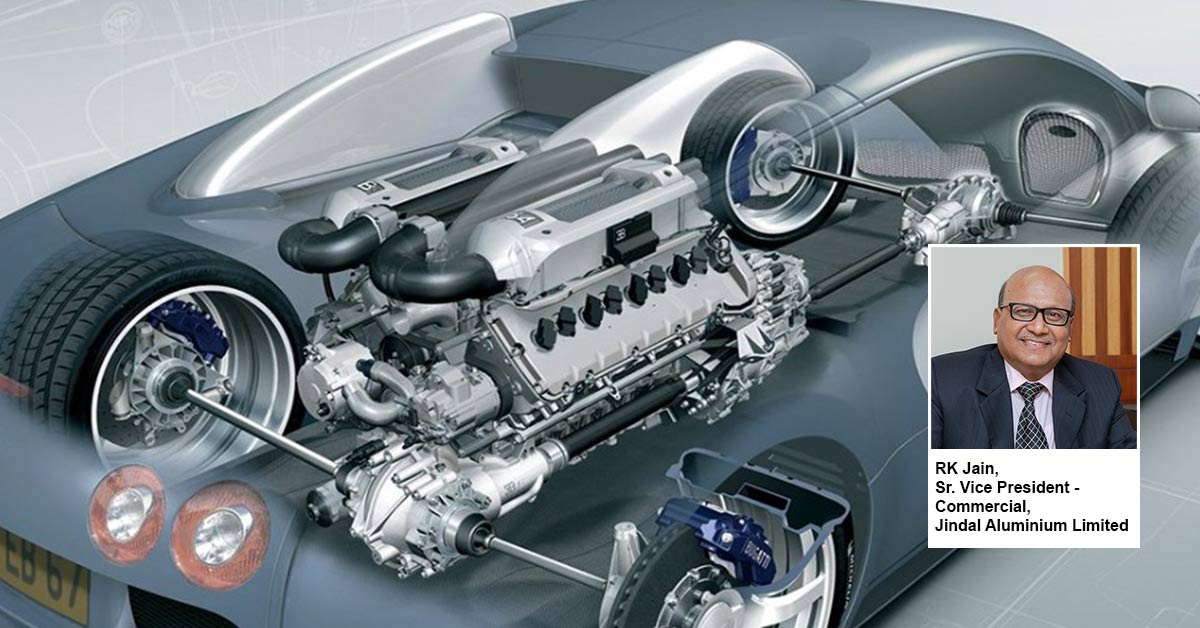

Blessed with a high strength-to-weight ratio, excellent fatigue strength, fracture toughness, corrosion resistance, and good workability; aluminium extrusions make for being the ideal material for defence applications.

Aluminium sheets, forgings, extrusions, and various forms of aluminium alloys used in defence equipment manufacturing are imported. Of these, high-strength aluminium extrusions and sheets are the most widely used in defence equipment production.

The above spelled out policy changes of the Government of India will see an important development of high-grade specialty aluminium alloy extrusions being produced in the country for our defence sector. These particular grade aluminium extrusions and sheets capable of catering to different critical defence applications include missiles, military bridging systems, naval warships, various ammunition, and armaments; futuristic infantry combat vehicles etc.

Classified into seven series based on the addition of copper and zinc to achieve high strength, aluminium offers some of the best alloys for the defence sector to meet its stringent requirements. The defence sector has an extensive need for such aluminium alloys in manufacturing critical hardware for ammunition, missiles, rockets and rocket launchers, military bridges or airdrop platforms, cartridge cases, and military aircraft.

Being majorly imported to date, the switch to domestically manufactured aluminium extrusions which is ready to cater to such requirements, will ensure substantial cost savings on import and, in the process, benefit India’s indigenisation program or being ‘Atmanirbhar’ in need of our defence sector.

Building on know-how

Having scientific know-how and expertise to produce aluminium alloys for defence equipment using the right technology is highly demanding compared to the production of commercial aluminium alloys domestically, as they tend to crack.

Indian companies in commercial aluminium alloy manufacturing are champions in that space. They have been working hard by investing in research and development to produce new alloys in India, offering a successful performance of the end-product matching international standards.

To get the best strong aluminium alloy from domestic producers, they have been allowed to partner with foreign companies. These collaborations are expected to ensure that local production of high-strength aluminium alloys for defence is possible domestically.

Over the next five years, India has set a target of Rs 1.75 lakh crore worth of domestic defence manufacturing, including Rs 35,000 crore worth of military hardware for exports. As mentioned above, aluminium downstream companies in India need technology up-gradation and import of technical know-how by collaborating with other countries to penetrate the fast-rising local defence sector.

Various industry reports quoted in the media show that in 2018-19, our total defence production was valued at Rs 80,558 crore and exports Rs 8,320 crore. India is now looking at doubling this domestic production in defence and quadruple exports by 2025. The Indian downstream aluminium sector is already taking steps in partnering this growth in our indigenous defence equipment manufacturing by stepping up to play its role in both the domestic market and exports.

For more details, contact:

Deepak Mathur,

Sr. Vice President – Global Marketing and Sales,

Jindal Aluminium Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)