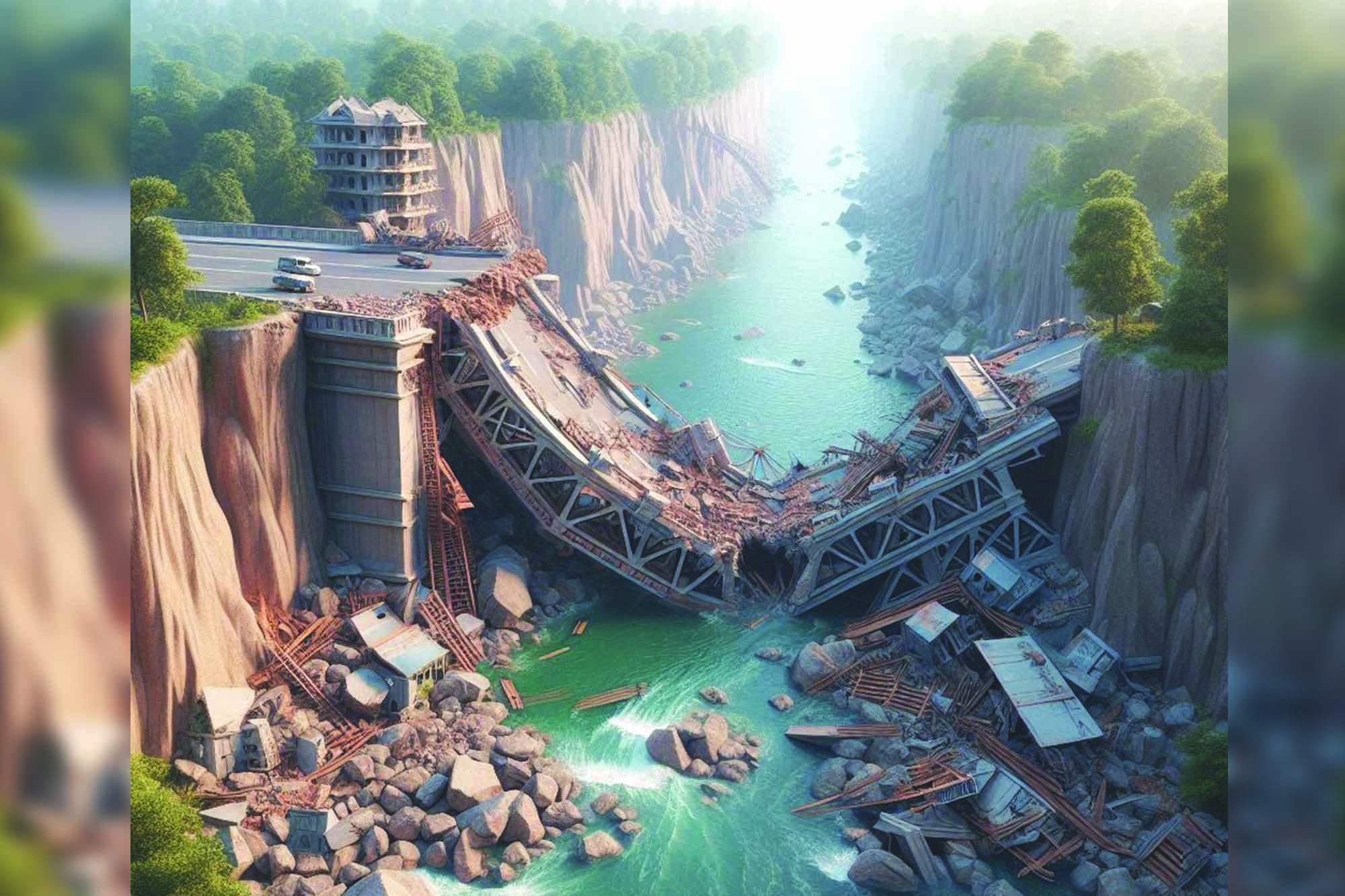

Fall of bridges

By Edit Team | July 12, 2024 3:13 pm SHARE

In June, over a span of 16 days, ten bridges collapsed in Bihar. This was a shocking blow to India’s infrastructure community as the nation strives for higher growth in road and bridge connectivity.

This situation underscores the urgent need to explore the transformative potential of technological innovation and strategic policy frameworks to fortify bridges and guide the industry towards safer, more resilient infrastructure solutions.

In recent months, Bihar experienced unprecedented bridge collapses across various districts, including Saran, Siwan, Madhubani, Araria, East Champaran, and Kishanganj. These incidents have severely disrupted transportation, affecting over 50 villages and endangering countless lives. The alarming frequency of these collapses, ten in just 15 days, has prompted state officials to scrutinise the quality of construction and the materials used.

The recent spate of bridge collapses in Bihar has brought critical issues in infrastructure management and construction practices to light. Within just a fortnight, ten bridges have failed, primarily due to poor construction, unscientific maintenance practices, and inadequate policies. These events underscore the urgent need for advancements in construction, structural engineering, and policy to prevent such disasters and ensure the safety and resilience of bridges.

Root causes of the Bihar collapses

Many of the collapsed bridges were constructed using substandard materials and techniques. Poor quality control during construction has resulted in strong structures that cannot withstand environmental stresses.

Improper dredging and desilting operations around bridge pillars have removed the necessary support bases, leading to structural failures. The increased water flow during the monsoon season further exacerbated these weaknesses. Many bridges in Bihar are old and must be designed to handle the current traffic load and environmental conditions. The lack of regular maintenance and updates to these structures has made them vulnerable to collapse.

Preventing bridge collapses

Bridge collapses can result from various factors, including natural disasters like earthquakes, design flaws, poor maintenance, and human errors during construction. In India, where climatic conditions vary widely and infrastructure is under constant pressure due to population growth and heavy usage, these factors become even more critical. Each collapse is a stark reminder of the importance of proactive measures in construction and ongoing monitoring to prevent catastrophic failures.

Innovations in structural engineering

Integral abutment bridges are gaining traction due to the durability issues associated with traditional bearings and expansion joints. This design eliminates the need for expansion joints, prone to failure and high maintenance costs. Integrative abutment bridges enhance overall structural integrity and reduce long-term maintenance needs by creating a continuous connection between the bridge deck and abutments or piers.

High-strength steel alloys represent a significant advancement in bridge construction due to their superior durability and resistance to corrosion. These materials are crucial for maintaining the structural integrity of bridges, particularly in regions with harsh environmental conditions.

Fibre-reinforced polymers (FRP) are becoming increasingly popular in bridge construction thanks to their high strength-to-weight ratio, corrosion resistance, and durability. These materials are particularly effective in strengthening existing structures and extending their lifespan.

Multi-beam steel-concrete composite decks with hot-rolled girders offer economical and effective solutions for short—and medium-span bridges. This design leverages the strengths of both steel and concrete, providing enhanced flexibility and strength while reducing construction time.

Innovative beam-to-pier joint designs simplify construction and assembly procedures while ensuring the effective transmission of forces at supports in continuous beams. This method employs traditional shear studs at the interface between steel beams and concrete slabs, improving the structural behaviour of the joints.

Using prefabricated and precast concrete elements in bridge construction allows for faster construction times while maintaining high quality. This approach reduces on-site construction risks and ensures uniformity in structural components, enhancing overall safety.

Advanced preventive measures in steel and concrete

Steel structures rely heavily on corrosion protection to maintain integrity. Techniques like applying protective coatings such as galvanisation and using corrosion-resistant alloys significantly extend their lifespan. Regular maintenance and inspections are crucial to detecting and addressing corrosion early and preventing structural degradation.

Cathodic protection is another effective method for steel. It involves applying a direct electrical current to inhibit the oxidation process that leads to corrosion. This technique is particularly beneficial in environments like marine settings or high-humidity areas where steel is more susceptible to corrosion.

Using High-Performance Concrete (HPC) formulations in cement and concrete construction is pivotal. These mixes incorporate additives like fly ash, silica fume, and other pozzolanic materials to enhance durability, strength, and resistance to environmental factors. Strict adherence to mixing designs, curing processes, and quality standards during production is essential to mitigate structural deficiencies, emphasising rigorous testing and inspection of materials.

Supplementary Cementitious Materials (SCMs) such as fly ash and slag are increasingly used in concrete mixes to improve durability and sustainability. These materials bolster concrete’s resistance to chemical attacks and reduce the environmental impact associated with cement production.

Migrating Corrosion Inhibitor (MCI) technology is critical in safeguarding reinforcing metal within concrete from corrosion. By delaying corrosion initiation and extending the structure lifecycle, MCI technology enhances durability and sustainability. Its application during construction and as part of maintenance and repair systems for existing structures proves highly effective in ensuring long-term structural integrity.

MCI technology in action

Migrating Corrosion Inhibitor (MCI) technology protects reinforcing metal within concrete structures from corrosion, significantly extending their lifecycle. By delaying corrosion initiation, MCI technology helps maintain structural integrity and reduces the need for frequent repairs and replacements.

In addition to their protective benefits, many MCIs are manufactured using renewable raw materials, making them conducive to earning LEED credits and promoting sustainable construction practices. This aspect aligns with global efforts to enhance environmental stewardship in infrastructure projects by minimising resource consumption and reducing environmental impact.

The Maslenica Bridge in Croatia exemplifies the practical application of MCI technology in a corrosive environment. During its restoration, the bridge underwent a process that included water-blasting to remove spalling concrete. Subsequently, CorrVerter MCI Rust Primer was applied to exposed rebar, followed by a coating of MCI-2020 across the entire concrete structure. These measures were implemented to prevent future corrosion, ensuring the bridge’s longevity and structural reliability.

Similarly, at Prince Mohammed Bin Abdulaziz Medical City in Riyadh, Saudi Arabia, exposed rebars faced potential corrosion due to construction delays and harsh environmental conditions. Utilising CorrVerter MCI Rust Primer and MCI CorShield provided effective protection against corrosion, safeguarding the structural integrity of the medical facility. This application underscores the critical role of MCI technology in preserving infrastructure durability and performance under challenging circumstances.

Policy and government initiatives

Ensuring resilience in infrastructure begins with enforcing stringent building codes and standards. These regulations are essential to guarantee that bridges are designed and constructed to withstand anticipated loads and environmental conditions. Regular updates to these codes, incorporating the latest advancements in materials and construction techniques, are crucial to address evolving challenges and ensure long-term durability effectively.

Implementing comprehensive inspection protocols and conducting periodic structural audits are critical components of resilience-building efforts. These audits, performed by independent, certified engineers, objectively assess bridge conditions. They help prioritise maintenance activities, ensuring timely repairs and interventions to maintain structural integrity over time.

Policies aimed at extending the lifespan of bridges play a vital role in infrastructure resilience. While engineering regulations typically design structures with a lifespan of around 50 years, regular maintenance can significantly prolong this period. Policies mandating scheduled maintenance and providing adequate funding for upkeep are essential to maximise the longevity of bridges and avoid premature replacement.

Public-Private Partnerships (PPP) offer a sustainable funding model for infrastructure projects, including bridges. These partnerships enable timely repairs, upgrades, and modernisation efforts by leveraging private sector efficiency and innovation. Collaborating with the public sector ensures oversight and support, enhancing overall infrastructure resilience through combined expertise and resources.

Effective risk management is another benefit of PPP models in infrastructure development. By fostering collaboration between government agencies and private stakeholders, these partnerships enhance risk assessment capabilities and facilitate proactive maintenance planning. Sharing knowledge and best practices between sectors fosters innovative solutions, ensuring infrastructure remains resilient and capable of meeting future challenges effectively.

Case studies and success stories

The Signature Bridge in Delhi exemplifies modern bridge engineering with its innovative design featuring a steel pylon and cable-stayed structure. Advanced corrosion protection measures and high-strength concrete were crucial in ensuring the bridge’s durability amidst heavy traffic and pollution.

The Mumbai Trans Harbour Link, currently under construction, employs state-of-the-art pre-stressed concrete segments and corrosion-resistant steel reinforcements. The project showcases India’s commitment to adopting cutting-edge technologies for sustainable bridge development.

Addressing the challenges of bridge collapses in India necessitates a proactive approach integrating technological innovation, advanced materials, and robust construction practices. By leveraging integral abutment bridges, steel-concrete composites, and advanced corrosion protection techniques, India can enhance the durability and safety of its bridge infrastructure. Moreover, strict adherence to quality standards, regular maintenance protocols, and continuous research and development will be pivotal in preventing future bridge failures and ensuring sustainable infrastructure development across the country.

As India invests in its infrastructure, bridging the gap between technological advancements and practical implementation will be crucial in building resilient bridges that can withstand the rigours of time and nature.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)