GETO aluminium formwork system for ease of handling

By Edit Team | January 29, 2016 6:16 am SHARE

With normative design in greater recyclable value, the aluminium formwork system of GETO can be handled and operated easily by the workers.

GETO system can control flatness and verticality in less than 5 mm, free of plastering both inner and external walls. It selects the most outstanding suppliers to assure materials quality (aluminium alloy 6061-T5, prop pipe, tubes). According to Samit K Patil, Managing Director, Oxygreen Constructions Pvt Ltd, “GETO products are not only guaranteed safe and qualified, but also with a feature of high overall value that could refurbish repeatedly.” From the prophase design to production, mock-up assembling, skill training, site technical guidance, quick response, centralised storage, renovating, old panels recycling and refurbished, formwork redesign, GETO can offer a one-stop service. With normative design in greater recyclable value, the aluminium formwork system of GETO can be handled and operated easily by the workers.

Positive impacts

With the advanced concept of quality, excellent design team, and years of rich practical experience, GETO formed four systems, including – Tie rod system, timber and aluminium formwork system, aluminium formwork with precast concrete system and flat-tie system.

• Tie rod system: GETO system made from the high yield strength aluminium alloy, which can be used repeatedly, strong but light and it is simple, flexible for assembly and dismantling.

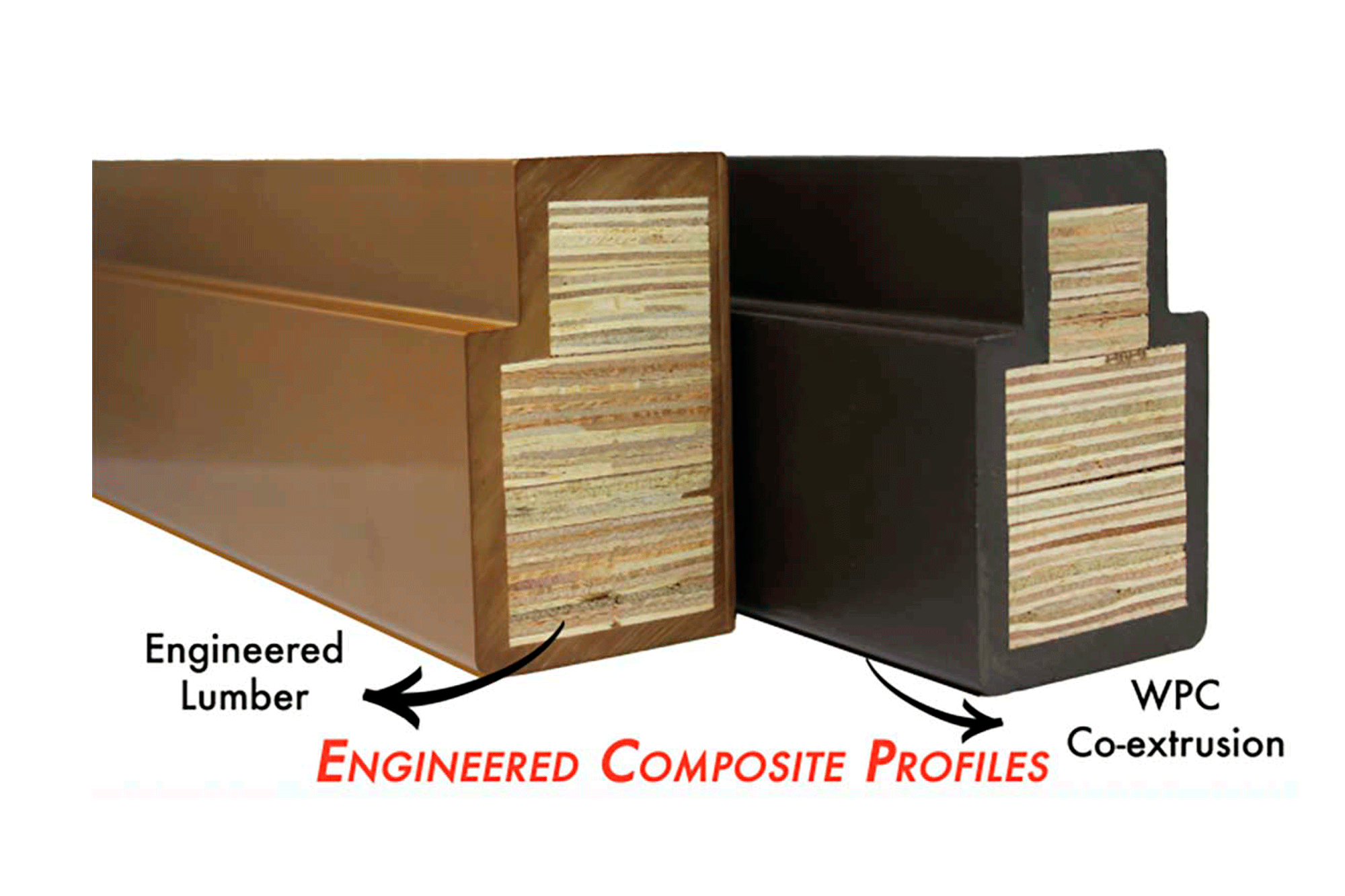

• Timber and aluminium formwork system: GETO use angle steel, bolt and special components to fix and reinforce, with optimisation, to save time and cost, thinking innovative to create the maximum value for client.

• Aluminium formwork with precast concrete system: Through repeated research and practice, GETO and Vanke had developed a brand-new product of aluminium formwork for precast concrete system, successfully in efficiency and precision. And the application of this technique will be widely used in the field of industrialised building.

• Flat-tie system: With the advantages of rich experiences, GETO adopted flat-tie system based on overseas market demands of 600 mm standard panels and flat-tie. All construction processes had been simplified by these fastening equipment.

Technology innovation

Talking about the technology innovation, Patil says, “Leading technology is the source power for us, in order to meet the high demands of domestic and foreign clients for product performance, GETO use BIM automation design systems, introduce big CNC cutting machine, a single row of holes hydraulic punching machine with two-cylinder, formwork refurbishment, developing automatic punching machine, welding robots and other automated production equipment, building a large-scale argon station.”

GETO R&D centre cooperates with Nanchang Hang Kong University, has established aluminium formwork system mechanics lab, material research lab, surface treatment lab, robot application lab and welding technology lab. Five major professional research labs are hold together to develop and optimise GETO formwork system, to enhance study in new materials, structural mechanics and welding technology.

formwork system, to enhance study in new materials, structural mechanics and welding technology.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.