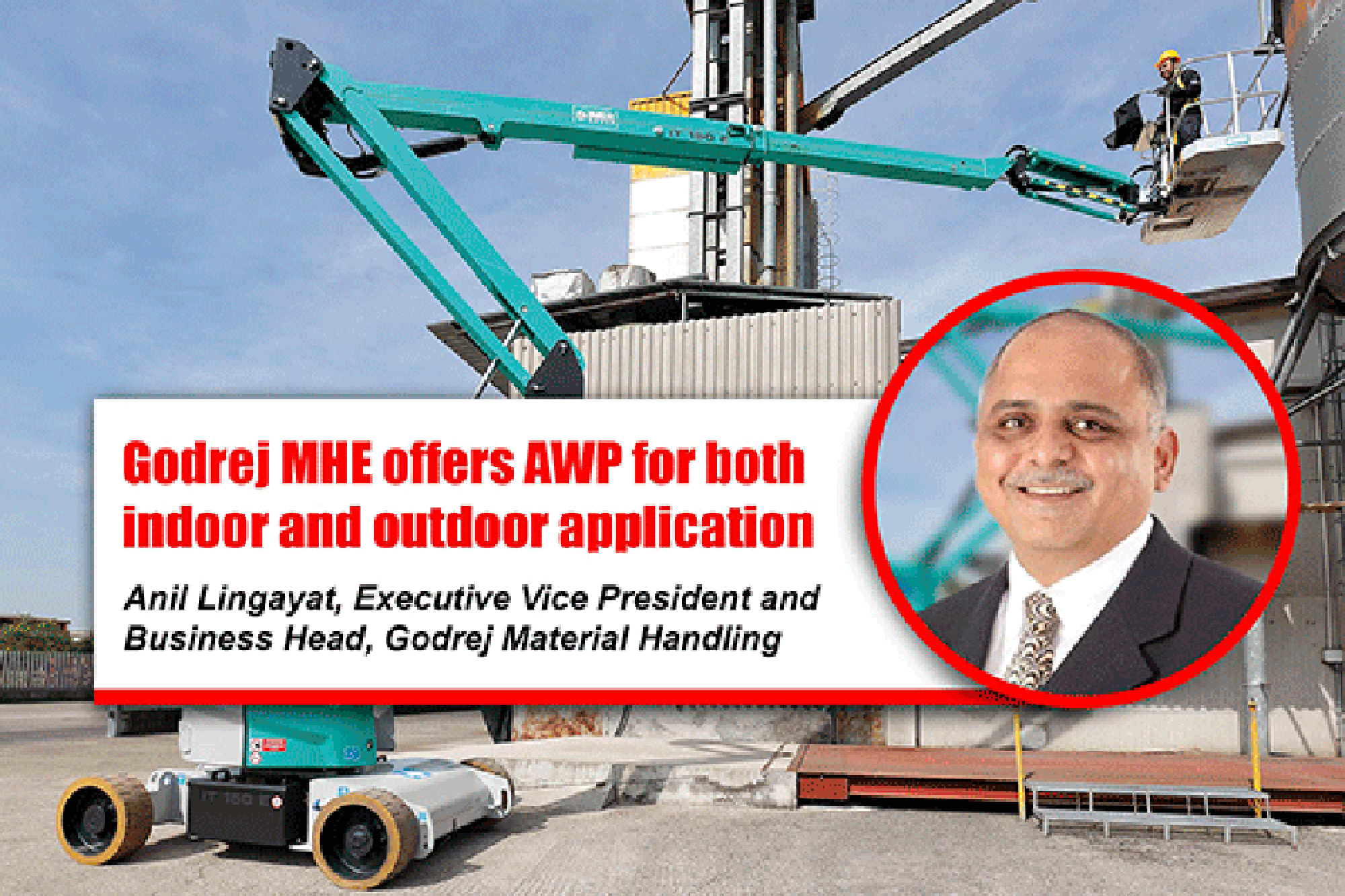

Godrej MHE offers AWP for both indoor and outdoor application

By Edit Team | May 11, 2020 7:15 am SHARE

The company’s product range includes scissor lifts, boom lifts and crawlers says Anil Lingayat, Executive Vice President and Business Head, Godrej Material Handling.

Tell us about Godrej MHE’s glorious journey

Godrej Material Handling has been providing Aerial Work Platforms (AWP) for more than a decade in partnership with IMER, Italy. IMER has been a front runner in providing the safest machines which compiles to latest EN standards. These machines have no deration even at the extended platform.

The company believes in offering an optimum solution to the customer based on the current application and future requirements to ensure the investment made by the customer remains valid for years to come. We have supplied more than 600 equipment in the market which is backed by our extensive sales and service network with more than 70+ touch points across the country.

In the view of current market dynamics, what kind of forecast you have for the year 2020?

It is difficult to forecast with the market currently facing uncertainty and liquidity crunch. The AWP are used extensively across the infrastructure sector. It is to be seen how soon the infrastructure sector stands up post Covid-19. In the backdrop of social distancing becoming a new normal and increasing safety concerns at workplace, we believe will catalyse the use of AWP and shield it from the market inconsistencies over a period of two years.

When are the different variants of access equipment you offer to cater to different projects?

We have a complete range of AWP for both indoor and outdoor application, which includes scissor lifts, boom lifts and crawlers. These equipments are available in battery, diesel and bi-fuel (both battery and diesel).

From manufacturing plants, warehouses and infrastructure projects, our product range caters to a wide range of clients from different sectors. We analyse the existing and future requirements of the customer and suggest a solution to enhance safety and productivity at their workplaces.

We have equipment which can go sky high with a lesser footprint on the ground and with lateral deck extension parallel to the racks in a warehouse which becomes a winning solution for the customers. We also provide this equipment on rentals.

What steps are you taking to ensure trained maintenance and availability of support staff for your access equipment products?

We have a dedicated training department for training our field technicians. These technicians can be remotely connected with technical team to ensure quick resolution of any technical issues at the customer end to ensure high productivity.

What kind of machine monitoring software do you recommended for the safety and upkeep of an existing fleet of machines?

IMER products are based on philosophy of active safety where in any situation; the equipment will stop before operator enters in to danger zone. This makes IMER machines, the safest machines. IMERVIEW is a fleet management system introduced for rental companies to manage their fleet across multiple locations and provide timely alerts for predictive maintenance.

How has technology made AWP machines more user-friendly and efficient?

With the advancement of technology and a variety of products available, It has become easy for the customer to choose the right products based on their need and application. With requisite software systems in place, customers can monitor and evaluate the performance of the equipment in their rental fleet and estimate the profit garnered in the process.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)