How PEB can be a part of residential building

By Edit Team | February 20, 2017 12:41 pm SHARE

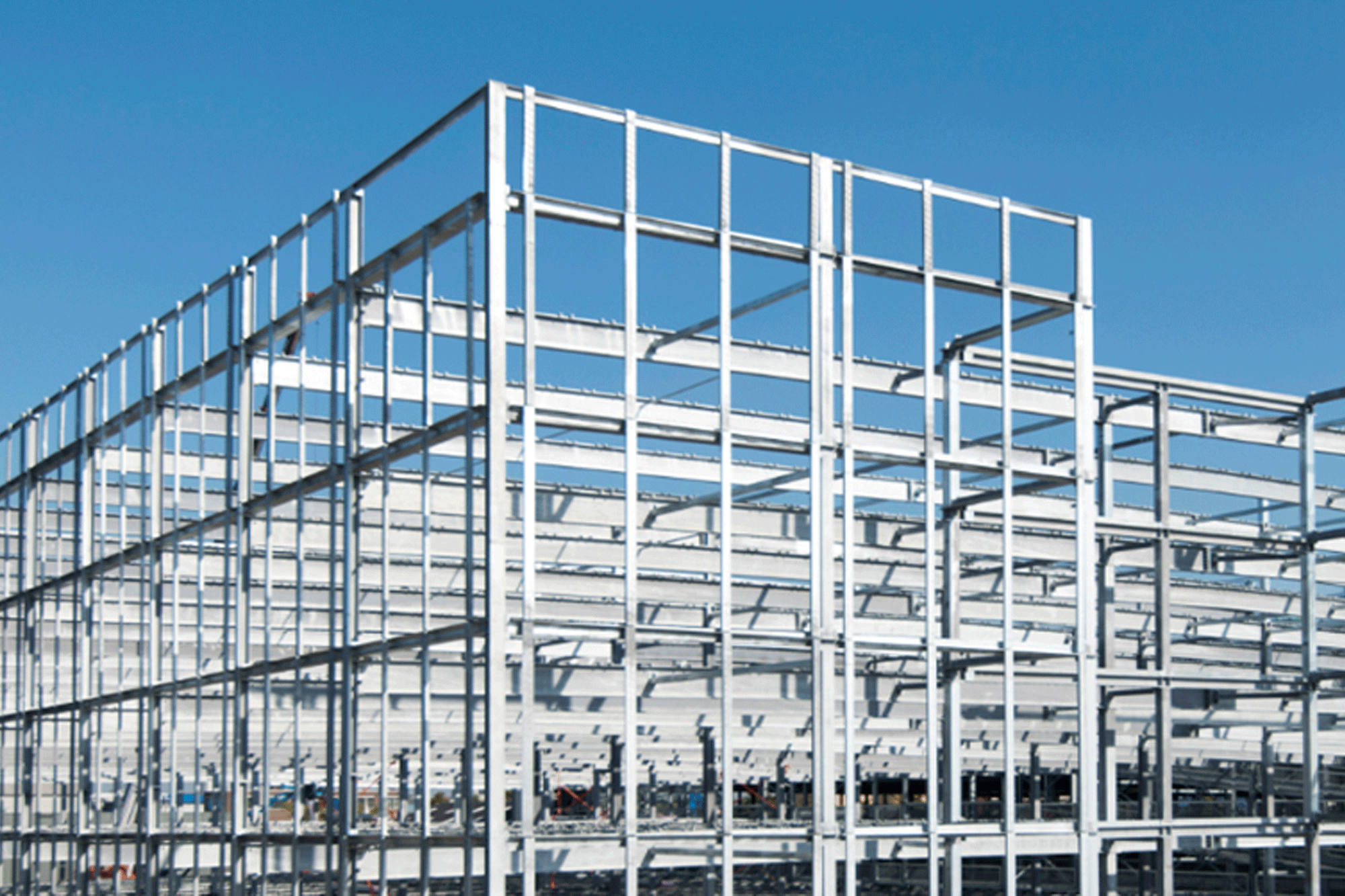

PEB is well accepted in construction industry and always being preferred for industrial applications. We take a look if PEB can be a part of residential building.

The quality of life has immensely improved as a result of the technological improvement. The revolution in the construction industry, especially Pre Engineered Buildings, commonly known as PEB is one of them. PEB has a history of more than five decades. However, its potential has been felt only during the recent years. This was mainly due to the development in technology, which helped in computerising the design and design.

PEBs are a common sight in developed countries like US. A survey by the Metal Building Manufacturers Associations (MBMA) shows that about 60 per cent of the non residential low rises building in USA are PEBs. The implementation of PEB is in industrial and many other non residential constructions worldwide. However, it is relatively a new concept in India and is garnering a lot of support.

Research and Markets recently published a report on the ‘Pre-engineered Buildings Market in India 2016-2020’. The report forecasts that the PEB market in India to grow at a CAGR of 16.15 per cent during the period 2016-2020. The report further states that the construction market in India has expanded significantly after the economic liberalisation in the 1990s. The introduction of PEBs has improved the construction market in India. Additionally, with the increased approval of FDIs and the Make in India campaign initiated by the Government of India, there has been a rise in the demand for infrastructure from all sectors in the country.

With the growing awareness on the usage of PEB, we share the views of some of the industry experts on how PEB can be a part of residential building. They also throw light on the product innovations they offer in this domain.

Multiple advantages garnering support

“The industry has witnessed change in adaptation of steel in high-rises both commercial and residential segments over the last 5-6 years mainly because of various advantages it offers such as off-site construction, speed, quality and timely completion,” says D Raju, Managing Director, Kirby Building Systems India Pvt Ltd.

He feels that the Indian construction industry is fast evolving with increasing acceptance of modern construction technologies with steel structures being one of them. He says, “Most of the high -rise structures are built either purely with steel or in reinforcement with concrete as steel has become one of the important part of any type of construction project may be bridges, rails, infrastructure, homes and high rise buildings.”

Decking panels and light weight material by Kirby

Sharing the offerings of Kirby in the PEB sector, Raju says, “Kirby provides high rise structures in combination with decking panels which are available in 41 mm, 54 mm and 75 mm depth. These decking systems are used in combination with concrete which is reinforced with steel beams with the slab thickness based on the loading factors taken into consideration on each of the mezzanine during the design stage.”

According to Raju, reinforcement model gives more stability as the combination of steel and concrete is the best for any type of building as they negate each other’s weaknesses and provide a rock hard building. This composite construction helps in making the building more fireproof as steel is more prone to fire than concrete and transfers heat at rapid pace.

Speaking about the light weight materials for all high rise buildings, Raju says, “All the high rise buildings by Kirby can be provided in various structural forms based on the customer’s requirement with adequate precautions being taken care such as fire proofing paint, corrosion resistant paint and high wind speed handling capacity at heights. These buildings are spread over bigger areas in vertical way and require large pool of skilled workforce to take care of all the activities so that the project work is executed successfully with safety and quality.”

Raju claims that Kirby has already constructed many high rise buildings across various other regions for different applications such as hospital, commercial and car park. “This erstwhile concept in India is expected to become a widely accepted solution with proven benefits for construction in the Indian environment in coming few years,” he adds.

Going vertical approach

According to Dr. Sandeep Gupta, Managing Director, Richa Industries Ltd, construction industry has already seen lots of transformations. “If we talk about PEB, it was earlier restricted to industrial and warehousing sector only, and then picked up commercial sectors and now gradually entering into residential sectors, This is a phase where concept of going vertical rather than horizontal are widely accepted in India,” he says.

Gupta feels that though steel has always been the preferred choice of construction, people have always hesitated hesitate to opt for steel construction in case of residential projects as this sector is still not completely explored. “Residential buildings have a different type of architectural requirement as compare to the industrial buildings which need to be focused properly. However, the advantages associated with steel construction such as faster completion, better aesthetics, cost effectiveness and more earthquake resistance will surely make PEB as the preferred mode of residential construction in near future,” says Gupta to support his views.

E-TAB, BIM software by Richa Industries

Speaking about the offerings by Richa Industries in the PEB sector, Gupta says, “Richa has successfully completed many industrial and commercial projects and started focusing on residential projects also. Low cost mass housing is the widely accepted concept nowadays in India and Govt also promoting it. PEB is very much affordable and will be the fastest construction technology to fulfil the dream of providing mass housing solutions.”

He further says, “Looking at the demand of multi-storey buildings in India, Richa has introduced various new technologies and Designing software like E-TAB and BIM in past one year. It helps to generate 3D model plans and elevations, provide accuracy in dimensions, fast object creation and the most important best tool for multi story designing considering all the seismic and load factors.”

As per Gupta, the other major advantages of PEB solutions will be easy alteration even at execution stage, lighter in weight and a more clear span. These technologies are expected to play very vital role in developing concept of smart cities also.

PEB, the fastest way of building construction

According to I V Ramana Raju, Chief (Sales & Marketing), Pennar Engineered Building Systems Ltd, PEB is the fastest way of constructing any buildings. He says, “Mostly in Indian residential market, the majority of the projects are delayed due to non availability of manpower and non adoption of latest construction technologies. More importantly, PEB is very advantageous as we can get materials to the site as per the sequence of the construction requirement which doesn’t need large storage space at site which is a major challenge in the urban areas.”

Ramana Raju also thinks that in PEB construction, lot of activities like interiors, plumbing, electrical works etc can be simultaneously done so that the project can be successfully completed within the scheduled time.

Light gauge cold form by Pennar Engineered Buildings

Sharing the company’s offerings, Ramana Raju says, “Our company has developed light gauge cold form buildings and supplied to North Eastern states of India and is currently in process of research and development to build up a product which would be much cost effective and faster construction in association with several technical experts.”

He further adds, “These cold form structures are already used as temporary shelters during the natural calamities like earthquakes, tsunamis, floods etc. As steel has high tensile strength, this technology would be beneficial for the hilly terrains and earthquake prone areas.”

Unmatched advantages hold the key

As per Gautam Suri, CTO and Founder, Interarch Building Products Pvt Ltd, in countries like America, Australia and Europe, the majority of construction in the housing space is done using pre-engineered steel systems for building.”All tall residential buildings abroad are built using pre-engineered steel due to its un-mated advantages over RC like fast construction, more floor area as steel columns take less space in comparison to RCC, no requirement of water curing or Shuttering, eco-friendly, low maintenance cost and earthquake resistance,” he says

Suri Further adds, “Pre-engineered steel buildings can be used to build farm houses, villas, G+1 floor house G+2 floor houses and even multi-storey

residential buildings.”

Educating architects and customers

Speaking about the steps taken by Interarch in the PEB Sector, Suri says “Steel buildings can be very easily customised as per architecture drawings, shape or size as per customer requirements. We are constantly trying to educate architects, direct customer and building about the advantages of steel and we are very hopeful that in future you will see all major construction happening in PEB only.”

However, the traditional constructions methods have been unsuccessful in meeting the increased demand for infrastructure from sectors suh as power, warehousing, fast moving consumer goods, automotive and logistics, and pharmaceuticals. The PEB technology originated in the US and was introduced in India by Middle Eastern vendors. One of the major challenges for adopting PEBs in India is the persisting trust in traditional Construction methods. with the rise in the awareness for these products is gradually increasing in the country.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)