Indian CV manufacturers gearing up for BS-VI

By Edit Team | August 16, 2019 8:28 am SHARE

The government decided to upgrade directly to BS-VI norms from the BS-IV norms that are currently implemented in the face of rising vehicular emission.

With the government pitching the stage to implement stringent emission norms BS-VI by April 2020, commercial vehicle manufacturers and OEMs in India have hastened the upgradation process of their product. Few of them have already launched some of their BS-VI series.

Taking a lead, Eicher Trucks and Buses, a part of VE Commercial Vehicles Ltd (VECV), in June lauched the country’s first BS-VI compliant light-duty trucks – the Eicher Pro 2000 series. The new range will be available in two variants – the Eicher Pro 2049 and the Eicher Pro 2095XP.

“We have a superior and long-standing expertise in manufacturing and exporting base engines for Euro-VI requirements of the Volvo Group for the last six years. This extensive experience with Euro-VI gives us the first-mover advantage to deliver products engineered to cater to the new emission norms in the country,” said Vinod Aggarwal, MD and CEO, VECV.

Bharat Stage VI norms in India kicks in starting April 2020 and VECV has completed the compliance test much ahead of the deadline. Volvo Eicher Commercial Vehicles already manufactures Euro 6 compliant engines from its plant in Pithampur, Indore and now The International Centre for Automotive Technology (ICAT), a division of NATRiP under the Ministry of Heavy Industries & Public Enterprises that has certified the engine which is as per the BS-VI norms set by ARAI and Government of India. The government accredited ICAT is one of the prime ‘Type Approval and Homologation’ agencies, also recognised by Central Pollution Control Board.

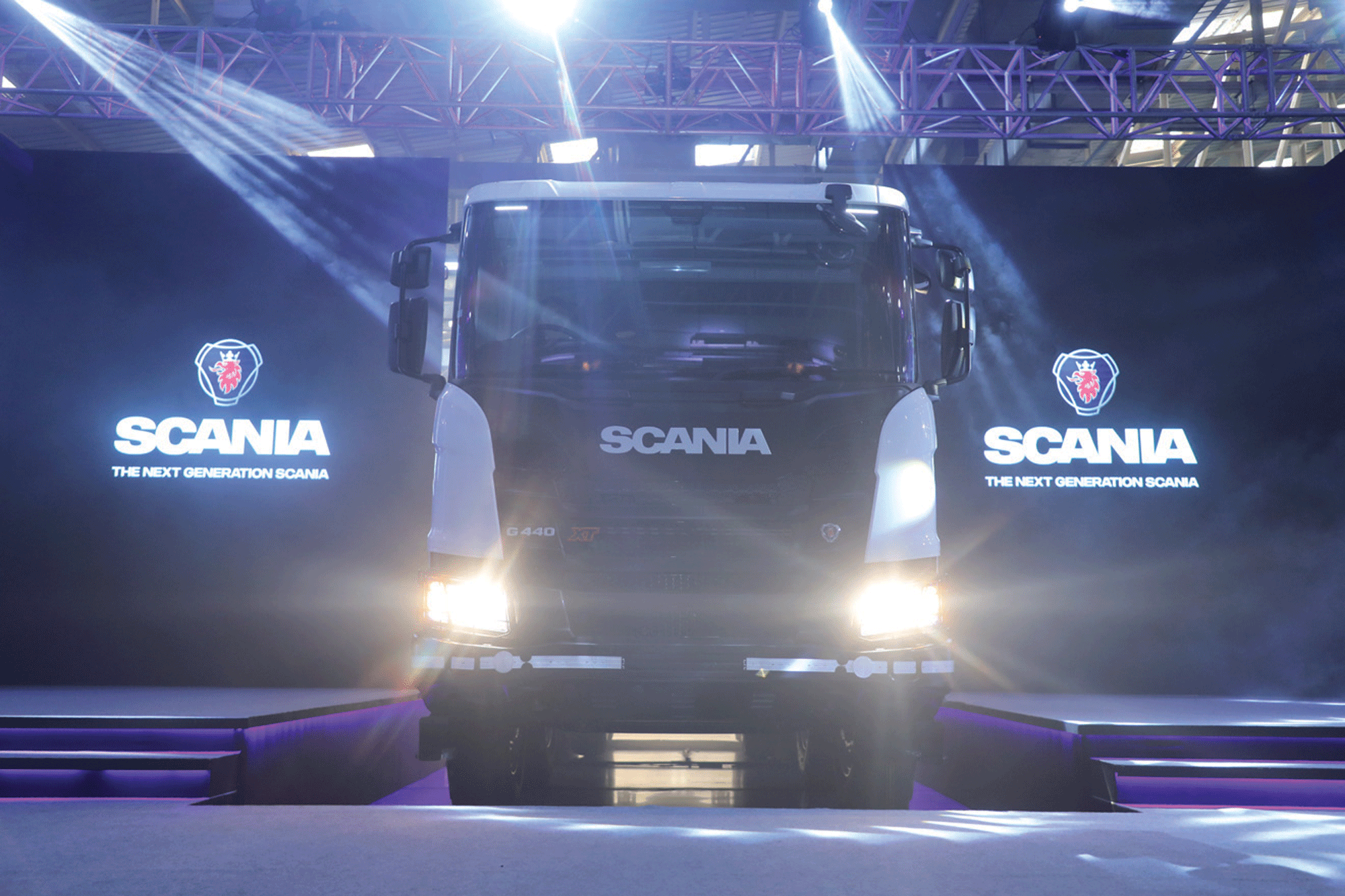

Following the trail, Scania CV India has launched their Next Truck Generation (NTG) to drive the shift towards sustainable transport solutions in the mining industry. With its unique modular system, this Next Truck Generation will deliver productivity-enhancing services as well as customised transport solutions, the company said in a statement.

The new range of NTG was launched at the Scania India Kolar plant in Karnataka. Petr Novotny, Managing Director, Scania India, says, “India is an important market for us and we are here to stay. The strategic introduction of Scania’s world-class range reiterates our commitment to the country. Today, with the launch of the NTG range, we aim to drive the evolution of India’s transport solutions in the mining, construction and long haulage business. We reinforce our commitment to helping customers achieve higher levels of profitability, safety, efficiency and productivity in their businesses. We are confident that these strategic initiatives will further support the growth of mining industry in India and strengthen Scania India’s growth story.”

As India moves closer to the implementation of BS-VI, NTG which is BS-VI ready is integrated with an upgraded powertrain, resulting in higher load carrying capacity, fuel efficiency and uptime.

“Globally our Next Truck Generation has won many awards. Very soon we shall also be introducing this Next truck generation for Long Haulage business. This generation of trucks is designed to better meet their requirements of increasing profitability. Inspired by our commitment to sustainability, NTG has efficiency in both fuel economy and performance. The new range of trucks will contribute to India’s ambition of becoming a sustainable nation,” Novotny added.

Bharat Stage VI or BS-VI emission norms will be implemented in India from April next year. The government decided to upgrade directly to BS-VI norms from the BS-IV norms that are currently implemented in the face of rising vehicular emission.

Srinivasa Raghavan, Sales Director, Scania CV India, said, “Recently we launched New Truck Generation – Heavy Tipper in India. With the strategic introduction of Scania’s world-class range we reiterate our commitment to the country. We are committed to helping Indian customers achieve higher levels of profitability, safety, efficiency and productivity in their businesses.”

Along with products the company is also focusing on continuously enhancing the service-related offerings for the future. Recently launched Central Parts’ Warehouse at Nagpur is an integral part of the company’s expansion strategy. Located at the zero-mile center of India, Scania’s state-of-the-art Central Parts’ Warehouse is spread across 30,000 sq. ft., with over 8,500 Stock Keeping Units while catering to Scania’s off-road, on-road and engine products.

“This strategic move closer to our largest distribution partner, L&T, vastly builds on synergies and improves the operational efficiency, reduces the order processing time for our customers across India, thereby resulting in better turnaround time and better availability of spare parts. It would help the customers achieve better Total Operational Efficiency (TOE),” said Raghavan.

Tech upgradation

In the near term, lot of technological developments have been associated with developing tailored products that are energy efficient, connected, durable and safer, thereby assuring the increase in profitability and reduction in costs and operating risks. Raghavan also briefed about certain developments taking place in the market.

Tailored Products: Time has come for smaller, smarter and more efficient solutions that help to eliminate waste and reduce environmental footprint. Whether it’s our in-pit trucks, service vehicles, outbound haulage, crew transport or industrial engines, there’s a need for using tailored products and vehicles in the mining and construction operations. With the technological advances, more powerful, energy efficient, lighter and durable products will be launched assuring the increase in profitability and reduction in costs and risks.

Real-time data connected vehicles: With advent of IoT there is an increasing realisation that the key to operational productivity lies in your ability to transform real-time operational and logistical data into valuable, actionable information which impacts their entire operation. Narrowed margins have forced customers to review their operations and apply principles of lean production to identify waste and problem areas across their sites.

Connected vehicles and service solutions are being specifically developed to equip customers with real-time logistical data from across their fleet and operations so that the decisions can be made based on facts, not fiction.

“At a macro level, we all know climate change, population growth, and urbanisation are all intimately tied to transport. Connectivity, electrification and autonomous transport technology are disrupting the traditional transport industry,” Raghavan added.

In the long term we see technologies associated with smart transport, energy efficiency, alternative fuels and electrification are paving the path towards fossil-fuel-free, autonomous and very safe transport systems.

Connectivity, electrification and autonomous transport technology are disrupting the traditional transport industry.

Srinivasa Raghavan, Sales Director, Scania CV India

Our extensive experience with Euro-VI gives us the first-mover advantage to deliver products engineered to cater to the new emission norms in the country.

Vinod Aggarwal, MD and CEO, VECV.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.