New tech and skill for better roads

By Staff Report | April 17, 2025 4:37 pm SHARE

India’s highway ambitions are stalling. However, innovative equipment, digital tools, and operator training could pave the way.

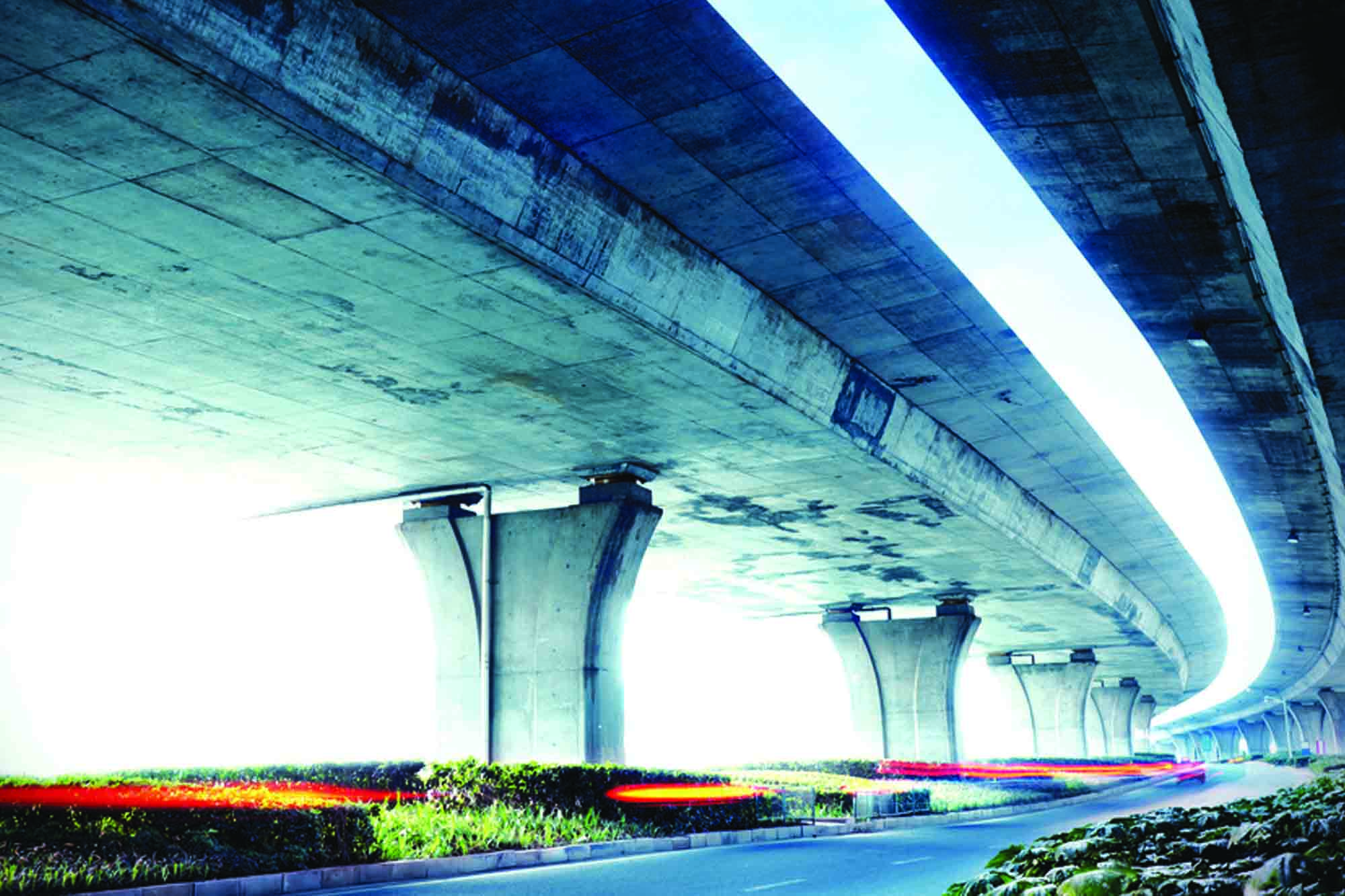

This April’s first week saw a striking milestone revealed by the national media. The National Highways Authority of India (NHAI) achieved a record capital expenditure of over ₹2,50,000 crore in FY25, surpassing its target of ₹2,40,000 crore. A 21 percent jump from the previous year. Beneath this financial flex lies a troubling reality. Highway construction plummeted to an estimated 7,000 km in FY25, a seven-year low, against a goal of 10,000–10,500 km, as the focus shifted to upgrading existing roads. Meanwhile, only 3,100 km of new projects were awarded in the first nine months of FY25, down sharply from 5,835 km in FY23. This delay signifies a deeper crisis for India, which has the second-largest road network in the world (6.67 million km), as quality problems like potholes, cracked surfaces, and premature wear are eroding years of development, even as the government plans to build 10,000 km of new highways in FY26.

The stakes couldn’t be higher for procurement professionals tasked with equipping these projects. India’s road infrastructure, the backbone of its USD 3.5 trillion economy, is faltering under land acquisition delays, funding hiccups, and outdated practices. Yet, amidst the rubble, a new wave of technology and skills training is emerging as a potential fix. From intelligent compactors to bio-enzyme stabilisers and digital oversight, innovative tools paired with a skilled workforce could mend the cracks in India’s highway dreams. But can they deliver fast enough to meet the nation’s ambitious targets?

A bumpy ride

India’s highway construction once roared at 50 km per day in FY20, a feat Union Minister Nitin Gadkari hailed as world-class. That pace has now sputtered. “The reduction in project awards over the past two fiscal years is the most significant factor,” explains Harsh Pareek, Regional Sales Director (India & SAARC) at Trimble Inc. Only 3,100 km of projects kicked off in FY25’s first nine months, a steep drop from 5,835 km in FY23, reflecting a pipeline running dry. Land acquisition remains a quagmire despite mandates to secure 80 percent -90 percent of land before bidding, disputes and slow compensation drag timelines. Election cycles and extended monsoons added to the woes, stalling approvals and muddying worksites.

Quality, however, is the real pothole. “Despite significant investments, maintenance and quality remain major concerns in India,” Pareek warns. “Frequent repairs, potholes, and poor road conditions increase costs and impact safety and transportation efficiency.” A 2024 NHAI audit found that 30% of recently built highways needed repairs within three years, often due to substandard materials or inadequate compaction. Rising steel and fuel costs – up 15 percent and 10 percent in FY25 – further strain budgets, forcing contractors to cut corners. This presents procurement professionals with a formidable obstacle: finding durable equipment without going over budget.

Reinforcing the roadbed

In areas where conventional approaches fall short, technology is stepping up. The 952 NX compactor from CASE Construction Equipment introduces intelligent compaction technology, a game-changer on a busy Gujarati highway. “India’s focus on strengthening its infrastructure has increased the need for advanced road construction equipment that delivers durable and high-quality results,” says Shalabh Chaturvedi, Managing Director of CASE India & SAARC. Equipped with a compaction meter analysing amplitude, frequency, and Intelligent Compaction Value (ICV), the 952 NX ensures optimal soil density in real-time. “This accuracy reduces rework, saves fuel, and extends the life of roads,” Chaturvedi adds. The outcome was a 15% reduction in project schedules and an extension of the road’s capacity to handle high traffic, which is crucial given Gadkari’s goal of halving accidents by 2030 with 25,000 km of four-lane enhancements.

Elsewhere, nature offers a surprising ally. TerraZyme, a bio-enzyme soil stabiliser, is rewriting the rules in Tamil Nadu’s rural hinterlands. “Enzyme-based road stabilisation presents a cost-effective, high-performance, and long-lasting alternative to traditional methods,” says Apoorva Modi, Vice President of Technical Operations at Avijeet Agencies. Unlike cement-heavy approaches, TerraZyme binds soil particles organically, slashing material costs by 20% and emissions by 30%. The Pradhan Mantri Gramme Sadak Yojana (PMGSY), which has been implemented over 2,000 km, has demonstrated its effectiveness in a variety of environments, including the sandy regions of Rajasthan and the black cotton soil that is prone to shrinkage in Rajasthan. Modi’s next aim is the National Highways under NHAI, where green technology might be scaled to motorways through trial projects.

Digital tools are the third prong. Trimble’s Building Information Modelling (BIM) and 3D machine control transformed the Dwarka Expressway, cutting errors and delivering on schedule. “By employing precise grading and earthwork technologies, we minimised costly rework,” Pareek notes. Real-time sensors now flag wear before it becomes a pothole, aligning with India’s tighter FY26 timelines. These innovations promise procurement pros a triple win: cost savings, durability, and compliance with sustainability goals.

The skill gaps

Technology alone isn’t enough; human hands steer it. “Well-trained operators ensure higher output and reduced downtime,” V R Ganesh, Director of Sales & Business Development, Vibrant Construction Equipments Pvt Ltd, asserts. At a Vibrant training site near Mumbai, operators master IoT-enabled asphalt plants, boosting uptime by 10 percent. Hands-on workshops and 24/7 support turn novices into precision drivers, a model CASE echoes with its operator programs. “Our strong service network and training help operators improve performance,” Chaturvedi says, pointing to the 450 NX’s electrohydraulic joystick that eases compaction tasks.

Kobelco’s ergonomic design goes one step further. In response to India’s lengthy workdays, the SK80 excavator, which was introduced in 2025, has a low-noise cabin to lessen tiredness. “The right skills help customers get the best from our equipment,” Ganesh emphasises. Projects are severely harmed by inexperienced operators who waste fuel, make mistakes with compaction, and shorten machine life. According to ICEMA, there is a 20 percent skilled labour shortage in India’s construction industry, which makes vendor-backed training even more necessary.

Cost vs. cure

These solutions pose a dilemma for procurement professionals: higher upfront costs versus long-term gains. CASE’s 770 NX, with its ECO mode slashing fuel use by 10%, or TerraZyme’s 20% savings over conventional layers, demands an initial investment. “The biggest hurdle is awareness,” Modi admits. “Contractors are stuck in old ways.” TerraZyme’s petition for permission from the Indian Roads Congress (IRC) is a slog. Steel price increases still hurt even though Vibrant uses buffer stocks and localised manufacturing to mitigate supply chain volatility.

Leasing offers a lifeline. “We understand the high capital investment required,” Chaturvedi says, detailing CASE’s financing options, including loans, leases, and hire-purchase deals. Vibrant echoes this, noting that PPP-driven trends favour leasing over buying, freeing cash flow as NHAI aims to raise ₹30,000 crores via asset monetisation in FY26. Digital tools like CASE’s myCASE telematics or Trimble’s analytics sweeten the deal, cutting downtime by 12 percent through remote diagnostics. “These ensure informed decision-making and maximise ROI,” Pareek says.

Voices of the road

The experts agree that the cracks are fixable. “Frequent repairs increase costs and impact safety,” Pareek warns, urging EPC firms to adopt modern practices. Chaturvedi sees hope: “Our compactors deliver durable results for India’s growing needs.” Modi champions sustainability: “Enzyme-treated roads have an extended life expectancy and require minimal rehabilitation.” Vibrant ties it together: “We empower operators for efficiency and safety.” These voices represent a change in the perception of procurement experts that technology and skills are the two main factors influencing quality.

Paving a smoother future

Let’s imagine the roads in India in 2030. Pothole-free asphalt ribbons were constructed using green alchemy, paved by intelligent machinery, watched over by digital eyes, and all driven by a workforce that had received precise training. The components are coming together, with 10,000 km planned for FY26 and 41,000 km of enhancements by the decade’s end. Equipment sales increased 26% in FY24 to 135,650 units (ICEMA), indicating the market is ready to grow.

Land delays, financing fluctuations, and skill shortages won’t go away quickly, so the path ahead isn’t perfect. They act as a call to action. Today, the ability to construct roads that connect cities and last for decades is at the heart of every procurement choice, whether it be for a skilled operator or a leased grader. The fissures are obvious. The solutions are available. It is time to roll up our sleeves and pave the future.

Quotes

Shalabh Chaturvedi, Managing Director, CASE Construction Equipment – India & SAARC region

“India’s focus on strengthening its infrastructure has increased the need for advanced road construction equipment that delivers durable and high-quality results.”

Nikhil Agarwal, President, CJ Darcl Logistics Ltd

“Our strength lies in our ability to offer end-to-end project control. This includes multimodal coordination, close liaison with authorities for special permits, and deployment of custom-built handling equipment.”

Moses Eddy, Director (Division Head – Sales & After Sales), Kobelco Construction Equipment India

“Our large excavators, including the SK380 and SK850LC, are engineered for maximum productivity and cost-effectiveness in heavy-duty road construction.”

Apoorva Modi, Vice President of Technical Operations, Avijeet Agencies Pvt. Ltd.

“Enzyme-based road stabilisation presents a cost-effective, high-performance, and long-lasting alternative to traditional methods.”

Harsh Pareek, Regional Sales Director (India & SAARC), Trimble Inc.

“Despite significant investments in road infrastructure, maintenance and quality remain major concerns in India. Frequent repairs, potholes, and poor road conditions increase costs and impact safety and transportation efficiency.”

V R Ganesh, Director Sales & Business Development, Vibrant Construction Equipments Pvt Ltd

“Our goal is to create eco-friendly, next-gen construction equipment by investing in sustainable technology to build a cleaner, greener, and smarter future for the construction industry.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)