Partnering India’s infrastructure with superior lubrication solutions

By Edit Team | November 18, 2022 3:35 pm SHARE

Construction and infrastructure (C&I) prowess mark any growing economy’s becoming and eventual success. India, here, is no exception. As one of the world’s fast-growing economies, India has placed C&I at the pivot of its growth story. India is expected to become the world’s third-largest construction market by 2022 and will require investment worth ₹ 50 trillion by 2022 for efficient development in the country.

As the sector prepares for this massive growth, associated industries, like the lubricant industry, are also driving research and development in innovation and technology to formulate products and services capable of facilitating some of the finest projects that will, in turn, positively impact economic expansion. Here, pioneers like Mobil™ Lubricants are collaborating closely with the private and public sectors to support India’s promising construction and infrastructure sector.

For world-class public goods

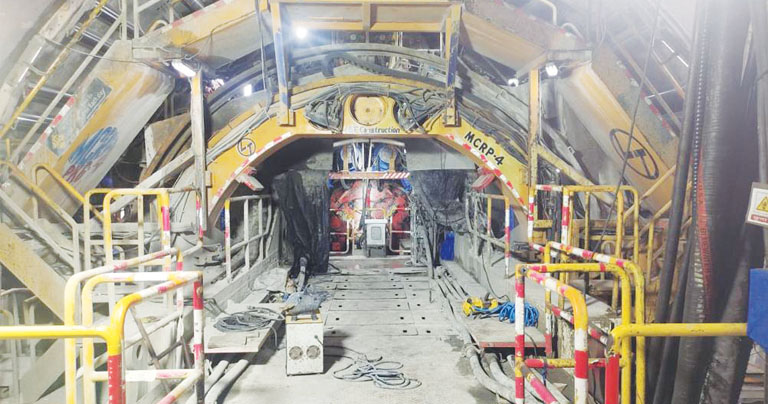

A key infrastructure project of interest today in India’s growing economy is the Mumbai Coastal Road Project (MCRP). This first-of-its-kind project in India is expected to decongest traffic in Mumbai, particularly South Mumbai. MCRP will connect Marine Drive with Kandivali through a 29.2 km coastal road projected to be used by 1,30,000 vehicles daily and is expected to reduce travel time between South Mumbai and the Western Suburbs from 2 hours to 40 minutes.

Situated on Maharashtra’s western coastline, the project consists of a first-of-its-kind under-sea corridor, with 40 feet diameter, in India. The development of the sea corridor requires sophisticated equipment such as a Tunnel Boring Machine (TBM) that will bore the 2.1 km tunnel section of the approximately 26-km long coastal road that runs through the bustling city of Mumbai. Named ‘Mavala’, this TBM is said to be the largest in India, with a length of 74 m and a diameter of 12.9 m.

This massive equipment also comes with sophisticated maintenance and lubrication requirements. As a pioneer in lubrication innovation, Mobil is providing its best-in-class lubrication formulations for the care, maintenance and continued performance of this TBM that has set records in India’s infrastructure growth story.

Tunnelling is a complex process where reliability is crucial, considering the aspects of safety, costly downtime, and complex breakdown maintenance due to site conditions. This TBM for MCRP is expected to operate continuously at high-temperature conditions to conduct heavy operations while resisting shock load. This necessitates using high-performing lubricants that will assist the equipment, minimise maintenance requirements and result in longer operating time. For these specific challenges, Mobil has chosen its most advanced hydraulic oils, gear oils, greases and services to enable the machine to perform at its best.

Lubrication for infrastructure excellence

The hydraulic drive of India’s largest TBM is being lubricated with the Mobil DTE™ 25 Ultra hydraulic oil that comes with better oil drain intervals, outstanding deposit control, and wear protection backed by Bosch RDE approval. Simultaneously, the main gear drive of the TBM is being lubricated with the Mobilgear™ 600 XP Series gear oils that provide up to 15-times wear protection as measured by the industry standard FAG FE 8 test. These oils also help limit equipment replacement costs through exceptional protection against wear and micro pitting.

The Mobil DTE 25 Ultra is part of the Mobil DTETM 20 Ultra Series, designed to offer exceptional performance in the harshest conditions. It helps industries achieve unprecedented performance goals quickly by lowering maintenance frequency and minimising man-machine interaction – making the site safer for industrial workers. Providing improved deposit control of 89.2 per cent for longer oil life and precision operations, the Mobil DTE 20 Ultra Series also delivers superior wear protection to extend component life*.

Additionally, the Mobilgear 600 XP Series lubricants are known for quality and consistency, as well as the ability to handle a variety of challenging gear applications. Formulated with high-quality mineral oils, they help to provide strong protection against corrosion of steel and copper-containing alloys, reduce sludge formation, increase oil service life, and resist foaming.

Redefining service for success

Mobil provides digital service assistance with its Mobil ServSM Lubricant Analysis (MSLA) program and onsite oil filtration program to guarantee continuous performance. The MSLA program has been developed to spearhead precise and informed oil monitoring and analysis and to assist businesses in achieving better efficiency. The MSLA program eliminates the time-consuming sample labelling process by delivering pre-labelled sample bottles with QR codes and a unique number identifier. This allows no additional sample labelling, improves sample process efficiency, and reduces labour and time requirements. MSLA also offers a distinct advantage in conducting oil sampling up to 66 per cent faster than peers**– translating into two-thirds savings in the expected time. For sophisticated equipment like the TBM, round-the-clock care and precise analyses provided by MSLA is significantly enhancing long-term performance.

Mobil is playing a pivotal role in facilitating the performance of this best-in-class TBM by providing a rich combination of lubrication solutions and smart services. Bringing its centuries-old legacy in superior lubrication formulation, Mobil will remain committed to associating with India’s rapidly growing construction and infrastructure sector – especially for public utility projects that demand innovation for universal good.

*This performance is based on the experience of a single customer. Actual results may vary.

**For more details, please visit mobilserv.mobil.com

(Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Esso and Mobil. For convenience and simplicity, those terms and references to “corporation”, “company”, “ExxonMobil”, “EM”, and other similar terms are used for convenience and may refer to one or more specific affiliates or affiliate groups.)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)