Robotic arc welding machines undergoing paradigm shift

By Edit Team | August 14, 2019 9:25 am SHARE

The trends towards automation and application of robots in the welding process are continuing due to the increasing industrialisation of huge growing consumer markets, development of new technologies and usage of new materials in the industry.

The welding equipment development activity in the country is in for rapid changes as per the market requirements. In the last few years, the users have preferred more use of advanced welding power sources. Which has given rise to the use of inverter technology and developed invertor-controlled welding power sources. These types of welding power sources are suitable for most of the types of the welding process. This was a gradual shift from the conventional transformers and the rectifiers as the efficiency of those type of welding equipment were very less and more power consuming and bulky and difficult to shift in shop floor and in site conditions.

With the invent of the invertor-based power sources the efficiency has increased to over 90 per cent and consumption of the power was also considerably less. These types of welding power sources are light in weight, easily moveable in the shop floors and are versatile in site conditions. According to R Srinivasan, President, Indian Institute of Welding, the development and introduction of power electronics and the use of Artificial Intelligence has made the welding equipment more user-friendly and capable of supporting the automation needs and meet the challenges of the welding industry. These advanced welding machines offer better welding characteristics which helps in achieving better quality of welds.

Welding sector undergoing paradigm shift

Welding equipment technology is undergoing significant changes. Last major change approximately started in the year 2000, when metal fabricators began to switch to IGBT inverter-based machine, primary purpose was power saving up to 30-35 per cent over conventional diode and thyristor technology.

Amrityoga, Sr Manager – Marketing, Panasonic Smart Factory Solutions India, says, “Currently, focus is on making the welding equipment smart by introducing various innovative waveform software and feedback system like encoder wire feeder. This feedback system is more forgiving to welder’s mistakes and helps him to achieve high quality and higher weld output. Also, internet enabled machines are under development so that they can make digital communication to remote server and all data can be made available to smartphones and computers.”

Robotic arc welding machines are also undergoing paradigm shift. Earlier there was power source and robot connected through serial communication. But now Panasonic has successfully introduced fast communication robots which communicate through bus bar communication (common CPU for power source and robot controller), the speed of communication is approximately 250 times higher as compared to serial communication.

Latest developments

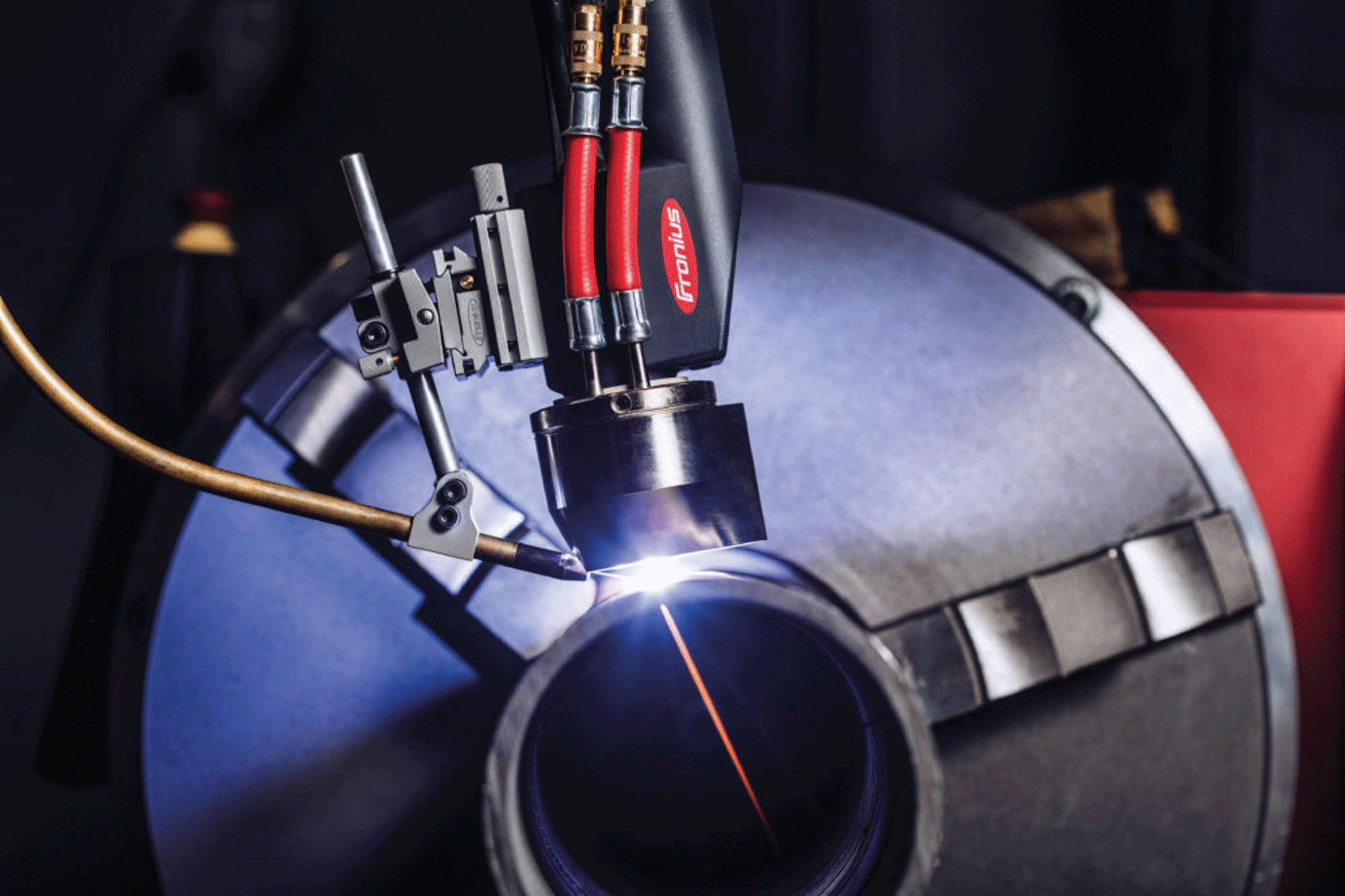

V V Kamath, Managing Director, Fronius India Private Limited highlights few of the developments:

TPS/i-Intelligent Series of Welding Power sources for GMAW Welding

With its modular design and the ease with which the system can be extended, the TPS/i is ideal for a wide range of manual applications. The various welding packages offer even more flexibility, with the advantage that the operator can switch the individual processes with speed and ease depending on the application. Regular software updates add to the functional scope offered by the system.

ARC TIG–GTAW welding power sources

The new TIG Welding Process ArcTig offers the optimal solution for all those who have the highest quality standards for their weld seam, while also seeking a simple and, above all, cost-effective solution. With mechanised and robot-assisted applications, materials up to 10 mm can be single-pass welded without processing.

Delta Spot-Resistance Welding Power sources

DeltaSpot delivers perfect welding results spot by spot. The indexing process tape offers advantages in terms of energy efficiency and heat input, especially in aluminium applications. A tip dressing of the electrodes is eliminated.

Amrityoga opines, “One of the latest welding robot technologies is remote laser welding robot system with direct diode laser. This technology is expected to be 5-6 times faster than current spot-welding robots and expected to replace current spot-welding robot within a decade. However, presently the price is high in the range of ₹2-3 crores, but slowly price is expected to come down and thus will become more affordable for the users.”

Automation increases productivity

The automation in the manufacturing sector helps to achieve high quality and repeatable quality of excellent products. According to Srinivasan, automation plays an important role in the productivity it also helps the skilled and semi-skilled persons to upgrade their knowledge and gives an opportunity to upgrade the skill levels. It further helps to create more opportunity to manufacture various support systems like welding: positioner, turn tables, rotators, requirement of software for various machines etc has increased the job opportunities. The use of automation has reduced considerable repair and rotators during the manufacturing time has resulted in increased productive time which has reduced the manufacturing costs.

The trends towards automation and application of robots in the welding process are continuing due to the increasing industrialisation of huge growing consumer markets, development of new technologies usage of new materials in the industry, the necessary modernising of existing production facilities and the need to be competitive in a global market. Energy-efficiency and light weight construction are the main challenges of the manufacturing industry. Kamath informs, “The potential of the use of industrial robots in the industry will substantially grow when robots will collaborate with workers and when the integration of the robot will become easier and we need highly skilled manpower for this integration.”

He further adds, “Automation is likely to continue for a future although better utilisation of the technology options may result in more manufacturing opportunities for countries with highly skilled labour forces, higher standards of occupational health and safety and well-developed quality assurance practices.”

Amrityoga says that Robotic Welding Automation is a reliable process and is overall 3-4 times more productive considering increase in productivity, repeatability, safety, quality, labour cost, reduced consumption of consumables. However, Robotic Welding Automation has the following limitations – a high volume of parts, a highly repetitive welding jobs and in-house programming expert to set the application. There is need for both – automation and huge number of manual welders.

Gas metal arc welding vs manual welding

The gas metal arc welding (GMAW), though was introduced in the country in the late 70s, did not make much impact till the year 1990 due its skill requirement and the acceptability of the welds produced by the GMAW. Later when the country started to produce more automobiles in the heavy transport vehicles, light motor vehicles and the two-wheeler industry with technical support and collaboration from countries like Japan, Korea and other Asian countries has changed the welding conditions of the auto sector.

Srinivasan explains, “Slowly these processes have taken root and replaced the age-old process of manual arc welding process and the gas welding in these sectors. The ancillaries which are attached to the automobile companies have also started the use of GMAW process and have found that the use of GMAW was acceptable in terms of better welding quality, productivity and the cost of manufacturing was lower due to the increased speed of manufacturing. Initially, only the transportation sector used GMAW process. At that time the countries welding depended to the tune of over 90 per cent on the manual welding process and the entire process was dependent exclusively on the skill of the welder.”

After the successful transformation in the auto sector, other industries such as railways, shipping industries started to use these processes and slowly replaced the manual arc welding. This enabled the welding equipment manufacturers to develop better quality of MIG/MAG welding machines which can support semi automation and automation. This has helped the industries to shift to the GMAW process. Today, we can say that dependency on the manual arc welding has reduced substantially and is around 65 per cent from the 90 per cent.

Further development in the gas metal arc welding process like the synergic welding process, STT and cold metal transfer technique, use of Artificial Intelligence has helped the industries to use these processes even in the critical areas of welding. This is possible due to the continuous research and development throughout the world has made the shift.

But the manual metal arc welding will continue to be in use at various levels. Even today in the fully developed countries the manual arc welding process still has 20-25 per cent share.

Arc welding is more efficient than that of gas welding. The main application area for manual arc welding is steel and pipeline construction. This welding process is also often used in the metal working sector. Manual arc welding is the preferred welding process for assembly work, as the mechanical effort is relatively low compared to other welding processes. Kamath says, “Manual arc welding can be carried out with fault-free results, even in unfavourable weather conditions, such as wind and rain. This is useful when working outdoors, for example. Another advantage of manual arc welding over other welding processes is that welding can often be carried out without any defects, even if the joint is not bare metal throughout. Manual arc welding can also be performed underwater. Manual arc welding has a market share of 5 to 10 per cent of the total consumption of weld-filler metals in Europe.”

Amrityoga informs, “On an average MMAW (manual metal arc welding) and GMAW (gas metal arc welding) constitute 90 per cent of total welding methods deployed.” But MMAW is losing fast to the GMAW process. At the start of the 21st century MMAW was approximately 70 per cent and GMAW 20 per cent. But now, in the year 2017, MMAW has been reduced to 50 per cent and GMAW increased to 40 per cent.

GMAW is almost 54 per cent more an efficient process as compared to MMAW, considering the following factors:

Deposition rate – the rate at which the weld metal can be deposited by a given electrode or welding wire in kg per hour.

Operating factor – the percentage of a welder’s working day that is spent welding.

Deposition efficiency – the relationship of the weight of the weld metal deposited to the weight of the electrode (or wire) consumed in making a weld.

Development and introduction of power electronics and the use of AI has made the welding equipment more user-friendly and capable of supporting the automation needs and meet the challenges of the welding industry.

R Srinivasan, President, Indian Institute of Welding

Currently, focus is on making the welding equipment smart by introducing various innovative waveform software and feedback system like encoder wire feeder.

Amrityoga, Sr Manager – Marketing, Panasonic Smart Factory Solutions India

Manual arc welding can be carried out with fault-free results, even in unfavourable weather conditions, such as wind and rain.

V V Kamath, Managing Director, Fronius India Private Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.