Screening solutions for rare earth elements and high-tech materials

By Staff Report | March 13, 2025 12:04 pm SHARE

As mining advances with trends such as urban mining, rare earth extraction, and digital automation, Ashar Locker’s adaptive screening technologies provide peak performance, decreased downtime, and enhanced resource recovery. They continue to innovate to drive efficiency and sustainability in the mining industry.

How do your screening media handle different ore and material challenges? Can you share a successful example?

To address this, we have various screening media that handle the issues provided by different types of ores and minerals using innovative methods and high-grade materials. Because each has distinct qualities, it is critical to understand the obstacles encountered during the screening process.

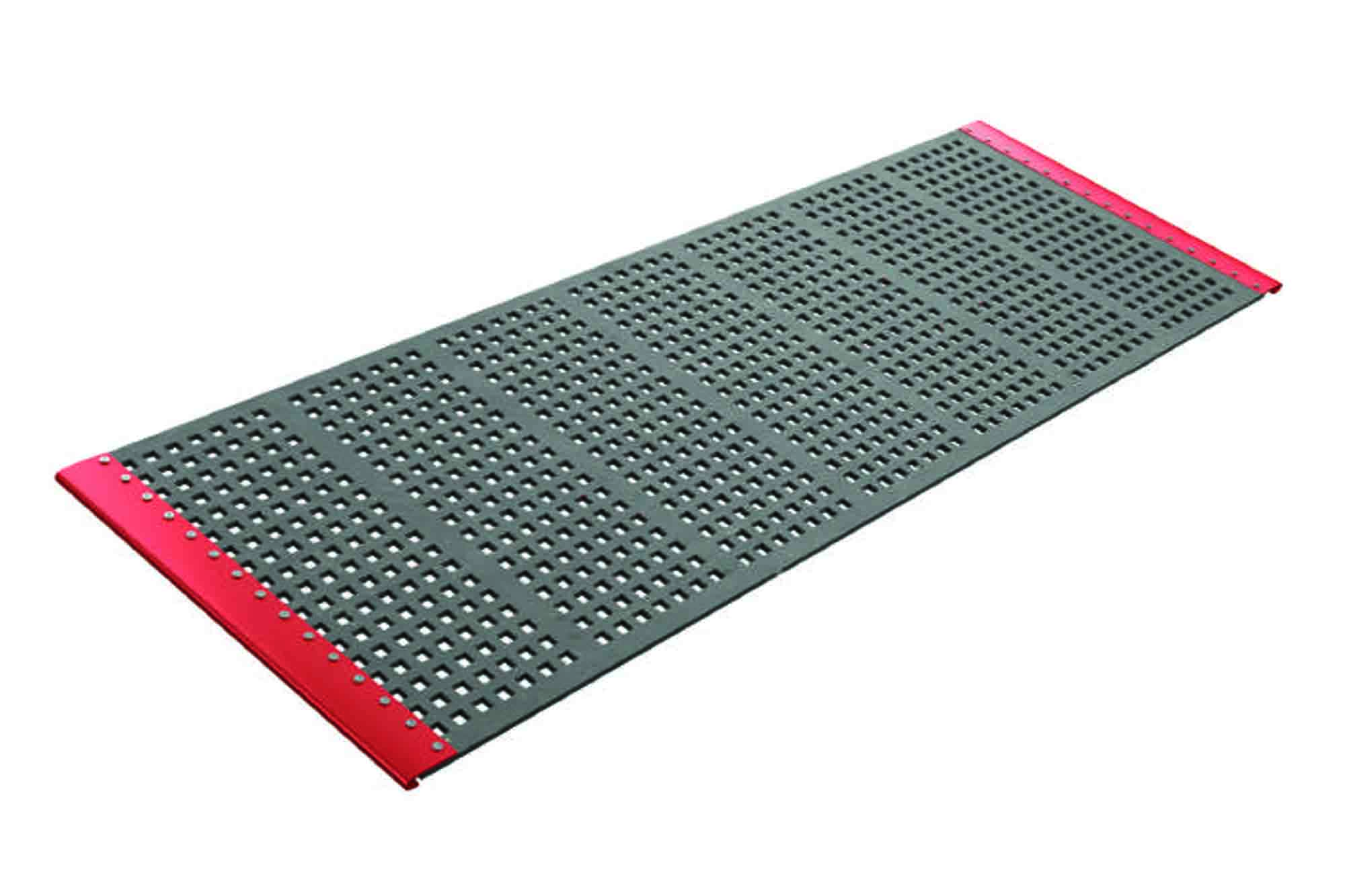

Cross-tension rubber Media is designed to extend the screening media’s operating life considerably. For example, we replaced the local wire mesh with our cross-tension rubber media at an iron ore location in Odisha, resulting in a 9-fold increase in operational hours. This media is long-lasting, easy to replace, and helps reduce noise pollution.

Furthermore, Poly Ripple Screens are intended to eliminate clogging and pegging, which are major problems with regular wire mesh screens. For instance, a well-known aggregate producer in Maharashtra experienced clogging concerns at their facility’s bottom deck. By using our Poly Ripple Screens, we were able to improve product quality and meet production targets.

Polyvenoharp Mesh, an anti-clogging mesh, is especially useful for materials prone to frequent clogging, such as LD slag. At one of India’s largest steel factories, we replaced wire mesh with Polyvenoharp mesh, resulting in a 5x increase in running hours and considerably improved product quality.

How do your screening solutions improve ore grade control and processing efficiency?

Our screening systems are intended to enrich ore grade control by ensuring that only the most appropriate material enters the processing stage of mining operations. Our customised screening media solutions can accurately separate ore. Our precision ensures that only materials that meet specific grade requirements are transferred for further processing. Our screens are designed for maximum efficiency, limiting the quantity of misplaced material (either too large or too small) that can degrade the overall grade. This results in a more uniform feed for the processing plant.

Screening solutions are designed to resist the extreme conditions seen in mining sites. This resilience guarantees continued operation with minimal downtime, allowing for consistent ore grade management.

Additionally, we provide experienced support and maintenance services to ensure screening systems operate at peak performance. Regular maintenance and timely support help avoid difficulties resulting in poor ore processing.

Implementing these modern screening systems may allow mining businesses to obtain more exact ore grade control, decrease waste, and ensure that only the finest quality material is handled, resulting in enhanced productivity and profitability.

How do your screening media support the circular economy in mining, particularly in recycling, slag processing, and tailings management?

Our screening medium are designed for effective material separation and classification, which is essential in recycling operations. Our screens can handle a wide range of materials, including metals, plastics, and building debris, ensuring that valuable resources are recovered and reintroduced into the manufacturing cycle. This decreases the requirement for fresh resources while also minimising trash.

Furthermore, we offer customisable systems for slag screening in steel plants, ensuring optimal recovery. This eliminates waste and improves the quality of byproducts from the slag screening process, which is currently employed in the road construction industry.

Tailings, or materials left over after extracting rich minerals, frequently contain residual metals and other recoverable resources. Our screening media can be used to reprocess tailings in conjunction with commercially available Screening Machines from various manufacturers, recovering additional valuable materials while lowering the amount of waste that must be kept or disposed of. This promotes more sustainable mining methods and decreases the environmental impact of tailing storage facilities.

What niche areas or emerging mining trends offer new opportunities for Ashar Locker’s screening media?

The demand for important minerals and rare earth elements, which are required for high-tech industries and renewable energy technologies, is rapidly increasing. Our screening media can be tuned to exact the separation and classification of these important materials, resulting in efficient recovery and processing.

Urban mining, which involves recovering valuable metals from electronic garbage (e-waste), is becoming more prevalent. Our screening technologies can adapt to handle the diverse and complex materials contained in e-waste, allowing for the recovery of valuable metals such as gold, silver, copper, and other recyclables.

Integrating automation and digital technologies in mining operations is a major development. We are focussing on implementing an automated system that will notify the user of any defects and the time required for replacement, improving the overall plant process and efficiency.

Another area where our screening technologies can be useful is mining phosphate and potash, which are used in fertilisers. Our screens can be tailored to the particular features of these minerals, resulting in efficient processing and high recovery rates.

How do your wire mesh, rubber, and polyurethane screens create effective hybrid solutions for mining?

Our hybrid screening solutions, which combine wire mesh, rubber, and polyurethane screens, provide a varied and balanced approach to meeting the diverse operational requirements of mining operations. Here’s how these materials combine in a hybrid system to provide the best performance:

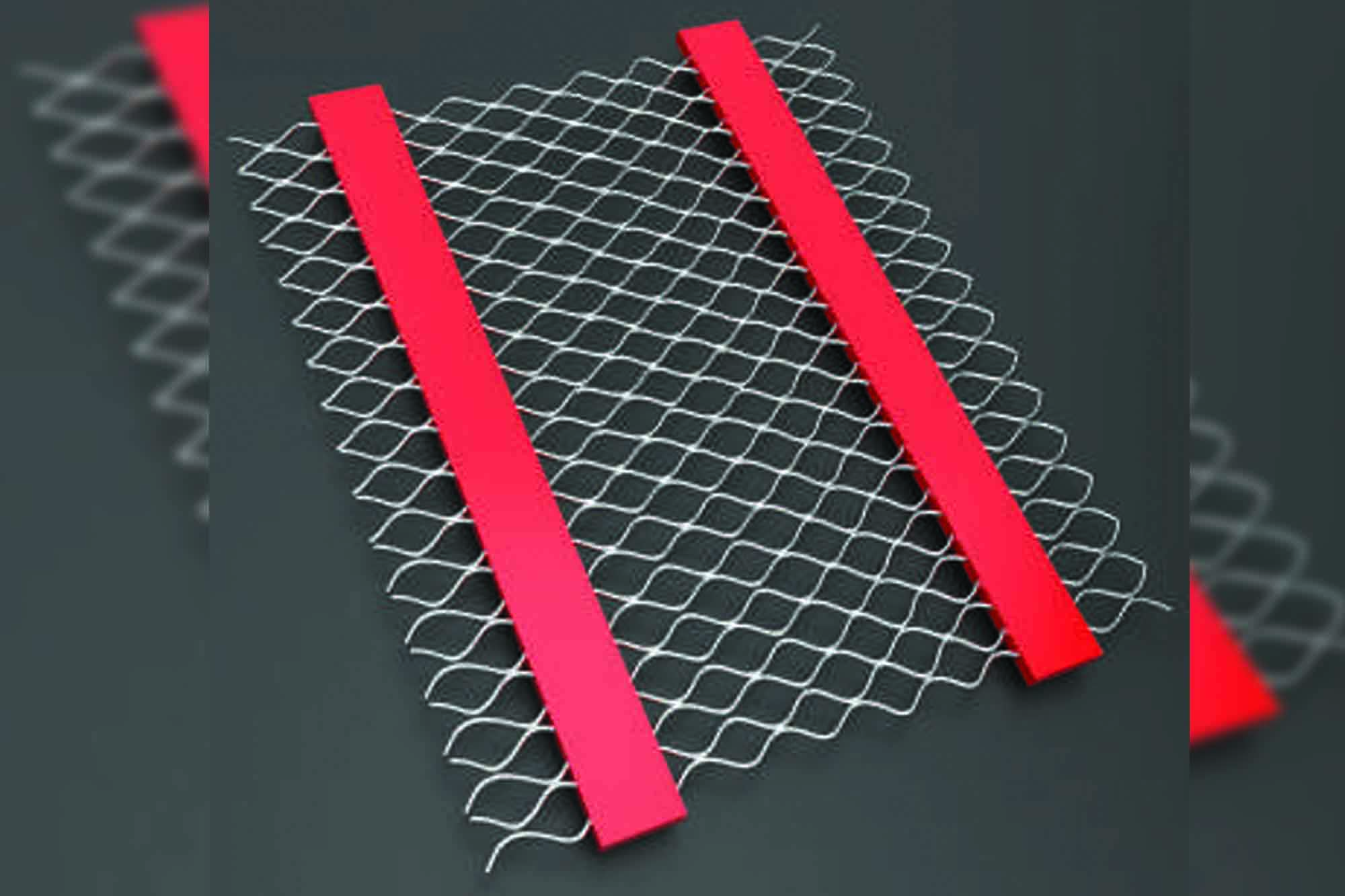

Wire Mesh Screens: These screens are noted for their strength and ability to provide exact screening. They are suited for applications that need precise separation and strong wear resistance. It is frequently utilised in dry screening procedures where the material is abrasive and requires precise separation.

Rubber screens: They have good elasticity, which helps to reduce noise and vibration during operation. They can also withstand impact and abrasion. They are appropriate for wet screening applications and areas where noise reduction is critical. They are also effective in working with larger, more abrasive materials.

Polyurethane screens are highly resistant to wear and tear, making them suitable for heavy-duty applications. They also have a longer lifespan than other materials. Polyurethane screens are ideal for high-impact and high-abrasion conditions, such as screening coarse materials or where regular screen changes are unfeasible.

Our hybrid screening solutions, which include wire mesh, rubber, and polyurethane screens, offer a balanced and adaptable approach to meeting the changing operating needs of mining operations. This combination increases longevity, improves screening efficiency, lowers maintenance and downtime, and provides cost-effective solutions for specialised applications. We harness each material’s capabilities to ensure that our hybrid screening systems perform optimally in various mining situations.

For more information, visit: https://www.asharlocker.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.