Steps to maintain metal buildings

By Edit Team | July 22, 2017 6:19 am SHARE

Featuring a few maintenance steps that help to keep a metal building functioning at its best.

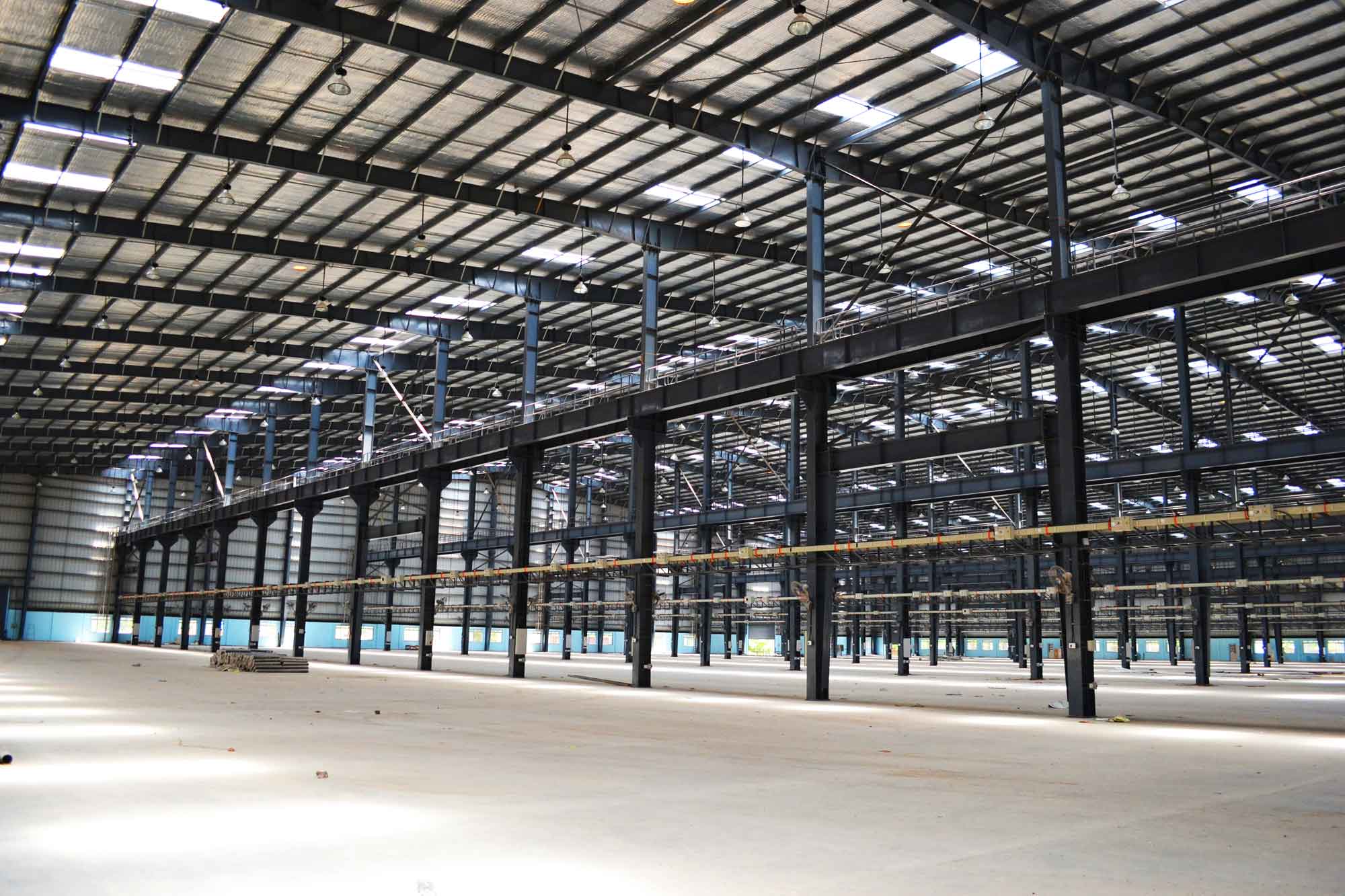

Ease of maintaining the structure plays an important role and is considered to be one of the major benefits while owning a metal building. Due to their durability and ability to withstand the elements, steel structures require a little repair and maintenance. So, here are few maintenance steps one should be aware to keep the building functioning at its best.

The importance of building maintenance

Due to various environmental and pollution related factors metal buildings and roofing assemblies require slight maintenance from time-to-time. “To achieve the desired life and functionality, maintenance of the building has been also important just like any other maintenance of plan and machinery and other equipment in your factory,” says Gautam Suri, CTO and Founder Director, Interarch Building Products Pvt Ltd.

Gautam highlights few maintenance tips that need to be considered during monsoon:

• Eave gutter and internal gutters should be thoroughly cleaned. Any dry leaves, dust or any other kind of items can choke the gutter drainage system.

• Roof inspection should be done to check for any damages to the roof sheets, flashings etc, due to man movement or animal etc.

• Opening of all downspout pipes should be cleared at the ground level for free flow of water from the roof and the pipe should be at least one foot above the ground level.

• Any modifications done on the roof sheeting by any other party, after building handover by Interarch, should be checked properly for leak proofing.

Maintenance of Pre-engineered buildings (PEB)

A preventive maintenance program is a key factor in maximising the life expectancy and dependability of the roof system, believes P V Rao, Managing Director, Pennar Engineered Building Systems Ltd. He says, “It is important to carryout periodic maintenance of your building to ensure trouble free service and extend the life span of the building. As a part of on-going maintenance program, periodic inspections, beginning at the completion of building are of utmost importance.”

Preventive maintenance should commence immediately after a project is erected, modified or repaired

Check for any debris that may have been left on top of panel or trim. Examples of this are ferrous items such as screws, pop rivets nails, sheet metal off-cuts, tin cans, etc, on the panel. The remaining smaller items may be swept-off with a soft nylon brush. This check should be made after any tradesman has worked on the building e.g, electricians, plumbers, air conditioning technicians and steel erectors.

Check for sand or dirt build up. These retain salt and moisture and will rapidly break down the paint and zinc layers resulting in corrosion of the base metal.

If building is in an area of high industrial pollution or close to marine environment then water alone may not be enough. Salt and other deposits build up at formed corners of panels and quickly breakdown the paint and zinc layers and finally corrode the base metal. As such deposits build up, the hardness of the layers increases making removal more difficult. In these cases the period between maintenance operations should be shortened and a mild detergent should be added to the initial washing water.

“Check the base of wall panels to ensure the ground level is at least one and a half below the bottom of panels. If windblown soil has built up at the base of the wall, it should be removed. If plants/shrubs etc, are around the building, make sure they are not touching the wall panels, particularly thorn-type bushes,” suggests Rao.

He adds, “Check all equipment which is located through or adjacent to any panel (roof or wall). Ensure there is no moisture build up on or near the panel; if there is, then corrosion is inevitable. If this condition exits, then modifications are required to avoid it.”

The following situations are examples of conditions to be avoided

• Water run-off from water services or air conditioners.

• Copper pipes fastened directly to the steel panel.

• Open water storage tanks or ponds adjacent to the panels.

If minor damage occurs to the sheeting or trims and paint touch is required, then the following procedure should be followed:

• Abrade the affected area

• Clean down with a solvent (e.g. sigma 9053)

• If base metal is exposed, apply one coat of zinc chromate primer. If base metal is not exposed, then primer is not required

• Apply one coat touch up paint available from Pebs Pennar steel.

Safety must be a primary concern

Rao opines, “Whenever you perform maintenance on the roof system, safety must be a prime concern. Building maintenance personnel should have fall protection and other personnel protection equipment. Failure to follow can result in serious personal injury or even death of the maintenance personnel.”

A completed roof system is a safe working surface except near the edge of the roof and when any moisture (such as dew, frost, snow etc.) makes the surface of the roof very slippery. Roof installations with steep slopes can also be hazardous without proper safety equipment. Appropriate safety measures and extra caution should be exercised whenever these conditions are present.

“Make sure maintenance personnel are adequately instructed in safety and that they are provided with appropriate safety equipment. Working off the ground, even a few feet, can be dangerous and fall from any height can be fatal,” asserts Rao.

Investing in a ‘PEB’ is a big step

Talking about pre-engineered buildings, certainly, steel is the prime construction material and is used as a base in manufacturing pre-engineered buildings. Dr. Sandeep Gupta, Managing Director, Richa Industries Ltd, “Investing in a PEB is a big step because of its strength and durability as these are maintenance free buildings and one can save recurring maintenance costs. And when these structures are designed to be care-free, still there are several maintenance items that should be done to maintain its aesthetics. This can save your money by keeping repair cost to minimum and preventing further deterioration of the building.”

Regular Inspection:

• Regular inspection of pre-engineered buildings is to be scheduled to identify the problems.

• Monitor the status of the building by maintaining a checklist and record the actions taken to resolve the problem, if any.

Gupta states, “An experienced person can conduct these inspections or a PEB manufacturing company can do it as a value-added service.”

Repair and maintenance of fasteners:

Small items like fasteners, screws, nuts and rivets that get loose should be tightened in a regular interval. Dust and sand on ferrous items should be removed by sweeping with a soft nylon brush and fasteners and screws that are damaged or rusty, should be replaced immediately.

Annual cleaning of Steel building:

• To maintain the exterior of PEBs and to prevent the build up of any fungus or harmful blemishes that further cause the damage of the structure, your steel structure should be washed annually with any of the household cleaning agent mixed with fresh water.

• Dust to be removed regularly from gutter and down take pipe for smooth flow of water.

• Skylights and wall light surface to be cleaned periodically so that proper sunlight may come inside the building.

Insulation:

Insulation is one of the most important factors to maintain building temperature. Damaged or weakened insulation can allow moisture which is very harmful to your steel structure. Increased moisture can also add to rust build up. Therefore a good quality of insulation material should be used while constructing PEB.

“Crane being used in PEB should not be overloaded as it leads to vibration and sound in PEB building.” He further states, “PEB in which acidic or alcoholic fumes are generated should be checked periodically, informs Gupta.

Steel manufacturers’ perspective

“From the steel manufacturer’s perspective selection of material and building design hold the key for the longevity of the metal buildings,” says Ranjan Dhar, CMO, Essar Steel.

Material selection

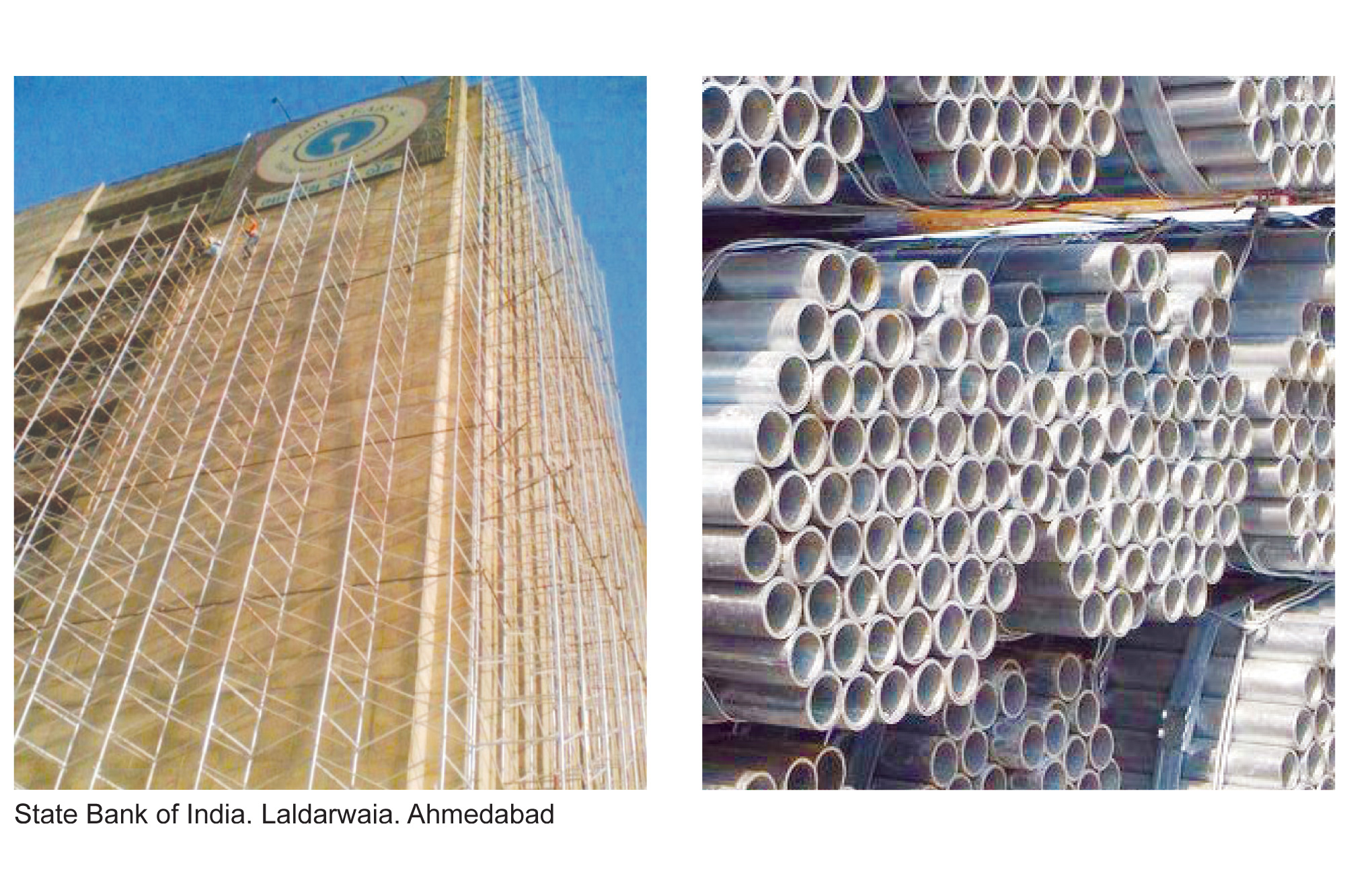

Dhar opines, “Steel as a building material is highly resistant, making it cheaper to construct, easier to maintain, and more durable over the long haul. Steel intensive structures are gaining momentum in all application areas replacing concrete structures because of its recyclability. Galvanised or pre painted sheets are used for better corrosion resistance especially in cold areas or in the marine environments. For longer life of the structures, steel with Galvalume (Al-Zn) coating is used. Galvalume products offer better corrosion resistance compared to galvanised products. Hence, appropriate selection of material holds the key for the longevity of the metal structures.”

Design of structure

According to Dhar, “Steel mills, PEB manufacturers and fabricators need to work in tandem to ensure that a robust structure is made. There has to be a standard or code which must specify the grades of structural steel to be used, fabrication process, types of electrodes to be used and protection issues with respect to durability.”

Steel in construction

“Policies must be made to embrace steel as preferred material for construction as it reduces the construction time is aesthetically better and process of construction is cleaner,” states Dhar.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.