Technology enabled, custom PEB is in demand

By Edit Team | May 9, 2022 2:34 pm SHARE

Leading PEB manufacturers and prefabrication specialists share reinvent buildings using customised materials, technology, and pre-engineered structures.

The Indian structural steel fabrication market is expected to register a CAGR of 5.5 percent by 2024. PEB Steel Structures in construction buildings are robust, rigid frames that are more cost-effective for your storage needs and a fully operating fulfilment centre. It can also save money by lowering the cost of component transportation due to relocation.

Pre Engineered Steel Buildings are manufactured or Produced in the plant itself. The manufacturing of structural members is done on customer requirements. The detailed structural members are designed for their respective location and are numbered, which cannot be altered; because members are manufactured with respect to design features.

Design and aesthetic concepts of the PEB structures

Earlier, pre-engineered buildings were limited to technologies like 2D drafting board, AutoCAD, and others where a curve of designed, detailed and fabricated effectively. But today, in terms of technologies for PEB we have certain kinds of sheeting, claddings, or framing among the others to build a sustainable building effectively. “This helps us ensure the minimum material loss, effective fabrication, and effective material management. Moreover, with the continual increase in the material prices, we cannot afford wastage of cost, resources, finances or time for that matter as this will further cause unnecessary project delays. Hence, I believe digital technologies help us deliver aesthetics with design implications”, says Sunil Lidkar, National Business Manager – Steel Solutions – India & SAARC, Trimble Solutions India.

Explaining the design trends further, Ashok Kulkarni, Managing Director, Nikitha Build-Tech Pvt. Ltd., talks about the large span structural designs are changing the project outlook of a PEB. In large span steel structures, the columns are reduced. This not just adds space of aesthetics, but comfort in terms of aesthetics, internal and external layout. The primary advantage of steel is, it can be altered and redesigned as per the changing requirement, whereas, civil structures don’t offer you this flexibility. There you will have to demolish the old structure every time to create a new one. It also requires additional investment. Also, the large span steel structures in a building can be altered for various utility purposes. A lot of sustainable drywall systems also are available in the market that can add flexibility while changing the layouts.

Another advantage is since large-span structures have beams with low depth, you can add a number of floors. So, large span structures allow the builder/developer to make optimum use of the buildings and utilise the floor are effective.

Obtaining uniqueness and enhanced efficiency with custom PEB

Decades ago, when we wanted to develop a customised solution or a customised building, the architecture needs to be different. By then it was easy for the architecture to do play with the drawings but implementation and execution of the same on-site used to be challenging for the project team. Sourcing talented people to execute such projects efficiently and on time was difficult during those times.

Noting the same, Sreerag C Kaimal, VP – Operations and Business Development, Steelton Prefab Infra Solutions Pvt. Ltd., says “Today, technologies like BIM, pre-fab structures and other PEB software have transformed the entire process and outlook of pre-engineered and customised buildings in India. Technology has eased the challenging part for the designers, architects and even the project team as most of the production is being done at the factory level. So, dependency on manual labour has been reduced. Even the materials required for the construction and designing are manufactured from the plant itself.”

This has further enabled us to keep meeting the project timelines and maintain smoothness in quality an efficiency in PEB. In a nutshell, PEB offer benefits in timeline, quality, accuracy and precision in the final project output. With these technologies, architects and other clients look at developing customised products, buildings and customised large span buildings and structures. And if the requirements are in tonnes or any specific requirement, then PEB are really capable to handle it better and can be flexible in terms of renovation and adding value to the projects. everything adds value to it. So, definitely, PEB has got an edge over the conventional structures when it comes to uniqueness and efficiency.

In a pre-engineered building, the concept starts from design architecture who integrates his thoughts into the design and detailing, considering the project

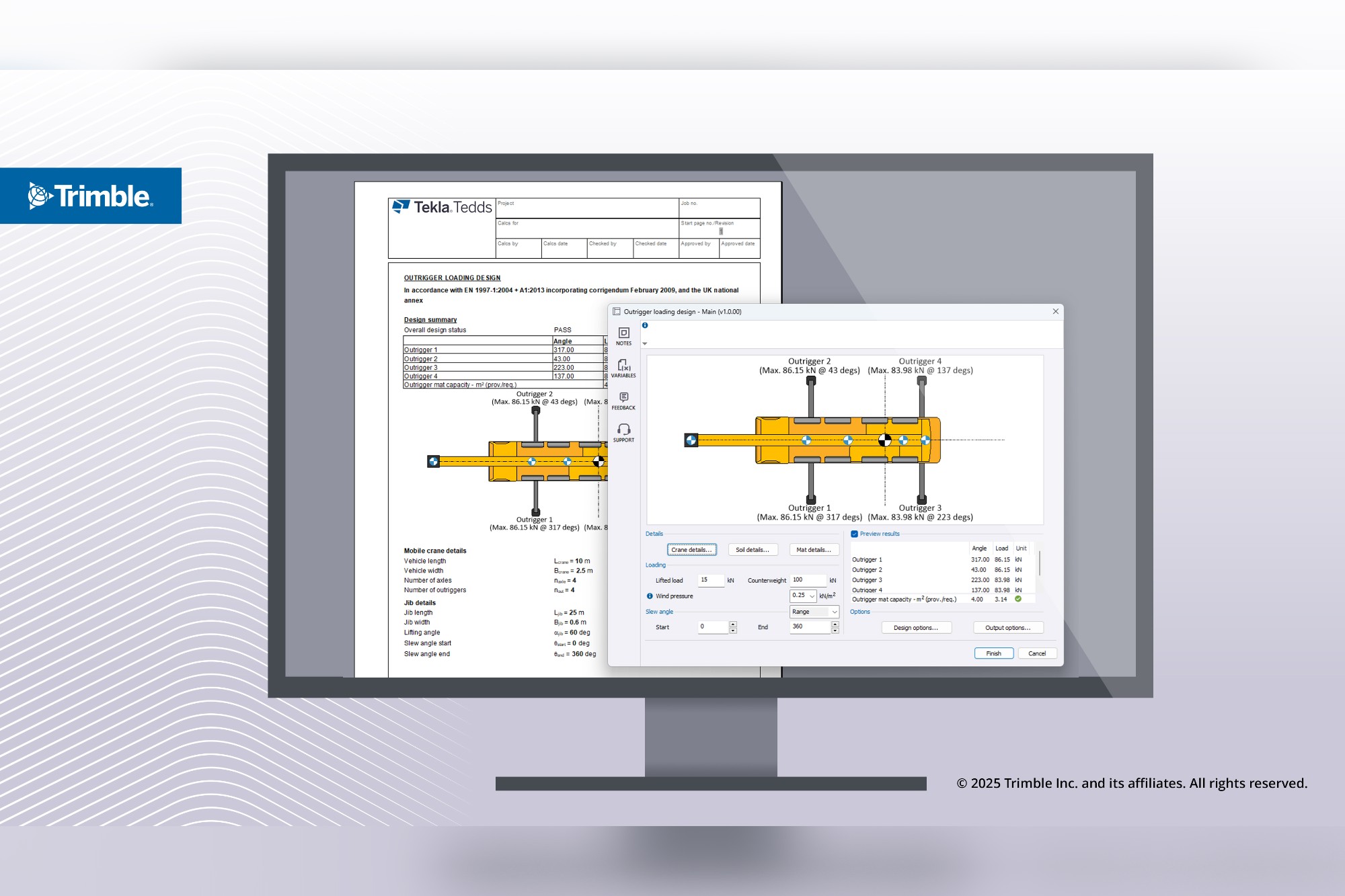

timelines and the project cost. Elaborating further on this, Sunil believes “Choosing the fabric as per the architectural requirement is imperative, and this is where technology plays the key role. Integration of technologies, with design and efficiency, may shrink the project timeline. Trimble’s Tekla software offers you the flexibility to manage your project in a phased manner, do the prefab accordingly, obtain the required material onsite and assemble them.”

Agreeing to Sunil, Ashok Kulkarni, Managing Director, Nikitha Build-tech India Pvt. Ltd., talks about how Tekla software helped them to manage their ongoing project, and their components of around 5000 metric tonnes have almost 2000 plus components. Here, with the help of technology, each component was identified and numbered at the factory, and then shipped on site. It further enabled us to easily locate and install the materials and required equipment, and commission install the entire project in three months. I believe technology has been an enabler for efficient construction and monitoring the PEB and large span construction projects.

Suggestions for structural maintenance for PEB

Whether it is a conventional building or a prefab building, we need a maintenance studio for the operations team, and the maintenance team to schedule and maintain a logbook for an annual checkup on PEB, says Sreerag. Also, the focus should be more on dealing with corrosion in structures, coating or any kind of physical damage that can hamper the prefabricated structures. Here, scheduling annual regular maintenance can ensure the safety and protection of PEB structures.

We do have technology and software for structural maintenance, that allows you to calculate the surface area, and the paints and coating required to protect that particular structure. “We also support our fabricators and manufacturers to pre-calculate the type of maintenance required for designing specified structures. Efficient maintenance practices will surely strengthen the life of pre-engineered structures”, Sunil concludes.

Customised design, aesthetics, and digitalisation can offer better product out in pre-engineered buildings. Sunil Lidkar, National Business Manager, Steel Solutions – India & SAARC, Trimble Solutions India.

PEB has got an edge over the conventional structures when it comes to the uniqueness and the efficiency. Sreerag C Kaimal, VP Operations and Business Development, Steelion Prefab Infra Solutions Pvt. Ltd.

Large span steel structures in a building can be altered for various utility purposes. Ashok Kulkarni, Managing Director, Nikitha Build-Tech Pvt. Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.