The 5 Emerging trends in Formworks

By Edit Team | March 20, 2017 9:51 am SHARE

A review at the upcoming trends in the Formworks vertical.

The prominent factor that shoulders the success of any construction project are the Formwork systems. It is this system that plays a key role in terms of speed, quality, cost and safety of the works. The increasing developments in this vertical are leading to some revolutionary changes. Let’s take a look at some of the prominent emerging trends in formwork industry.

As structures grow taller and floor plates bigger, end users are looking for formwork systems that our cost effective, light , reusable , safe , easy to use and de-shutter, durable and flexible.

Aluminium and Steel formwork gaining popularity

“There are very few companies in India that are able to cater to the demands by providing a totally integrated formwork design system for a specified project with fully engineered and compatible components,” says Hari Om, Director, BSL Scaffolding Limited. He points out that initially, the ply faced formwork found vast applications in most of the formwork usage areas. However, as a result of the challenges, the users are looking forward to new systems which are far superior to ply faced formwork especially in terms of reducing cycle time , cost effectiveness , reusability and other factors .

Commenting on the upcoming new verticals, he says, “In the current scenario non ply faced formwork systems like Aluminium formwork, Steel formwork, plastic formwork and fiber formwork are gaining popularity. Aluminium formwork leads the race as it is a cut above on all parameters that users need to move forward effectively in these days where high rises are a common solution to development in the fast moving urban world.

BSL Scaffolding Ltd is one of the leading Indian player in the Indian formwork space with vast experience of catering to the formwork needs of customers across the globe ,offering total formwork solutions. “We understand the formwork needs of our customers project provide them the best formwork solution backed with sound engineering expertise. We have our state of the art manufacturing unit at Haridwar producing full range of Aluminium formwork products with supporting systems and accessories. We have successfully executed major projects across India supplying fully indigenous Aluminium formwork solutions for high rises, villas and infra projects . We also provide special system formwork solutions for slabs, beams, columns and walls which minimise cycle time , give good ply face finish , reusability and cost effectiveness,” says Om.

Designing features that facilitate the industry

“Emerging trends witness in industry is modern modular formwork systems being designed with features that facilitate, accelerated and economical construction workflows in monolithic construction projects,” observes Shreeniwas Kelkar, Product Manager, Doka India Pvt Ltd.

Made to Measure scenario

According to Pradeep Ghumare, Director, NOE Formwork India Pvt Ltd the emerging trend in the international formwork scenario is ‘Made to Measure’ when it comes to formworks for civil construction and infrastructure projects. Explaining further, he says, “They are extremely versatile and can be exactly configured to suit any project and site requirements. The best example is NOEtec from NOE Formwork India Pvt Ltd.”

Balancing quality and cost

In recent times, there has been a considerable shift of focus from conventional formwork to system formwork in the industry, observes Vikas Mittal, Director, Wonder Mold Plast Pvt Ltd. He further adds, “People are looking for formwork system which reduces time , gives a good finish , lightweight and easy to use so they can reduce their labour cost and projects can be completed on time also being economical.” In short, people are looking for a system which can improve the quality of the structure while being economical.

Systematic safety

Safety is of utmost priority on the site. At Doka, safe solutions are an integral part of product philosophy and boost site productivity: they meet legal standards, help prevent accidents, assist with their speed and help comply with the schedule and also with completing projects below budget. A win-win situation – especially for users. Whether working and protection platforms, guardrail systems, access systems or tie-rod systems, Doka safety systems yield financial benefits for construction companies in addition to being flexible and easy to use.

Industry offerings

Apart from discussing the emerging trends in formworks, the industry experts also shared details about their valuable offerings for the formwork industry. We take you through some of their offerings.

Doka OneGo: Compact and light weight

Sharing details about the offerings of Doka, Kelkar adds, “The Doka OneGo aluminium formwork system is compact and lightweight enough to need only a few form-tie points and floor props. It has synchronised forming and stripping processes, integrated stripping aids such as a stripping head for floor-slab formwork and chamfered panel joints. The formwork can be reused immediately.”

The company claims that it has received a tremendous response to this system due to several factors like the scarcity of skilled man power, less cycle time and thirdly, multiple usage makes it an economical, better and safer option. “We believe, there is much more to be captured in the panel formwork segment and will be launching some new light weight products in the same segment soon for horizontal slab structures,” says Kelkar.

NOEtec: completing challenging jobs with minimum components

Ghumare claims that NOEtec completes challenging jobs using the minimum number of system components: (a) Specially designed NOEtec steel girder and its extending girder, which is the heart of the system (b) Unique connection NOEtec Bolts (c) Standard Lock (d) Strut (e) Collar (f) Header beam (g) Guide Pocket.

“Whether it is a tunnel with a rectangular or rounded cross-section, underground or cut-and-cover construction, wall formwork or a shoring system: virtually every project can be accomplished using NOEtec’s System Components only,” he adds.

Explaining the various applications of, NOEtec Ghumare says that it can be used as vault formwork, trough formwork, wall formwork, climbing formwork, travelling formwork, soffit formwork, tunnel formwork and integrated travelling formwork. As per company claims, the assembly time for the NOEtec formwork is short and that too with lesser manpower, as compared to the prevailing systems in India.

Nova Framex : a support for steel frames

Speaking about the company’s latest offerings, Mittal says, “Our Latest product is Nova Framex . It is a plastic formwork system which is sturdy and robust .It is a plastic panel with a light weight steel frame attached to it. The plastic used in this is a compounded material which has high impact properties and the attached steel frame gives it the required support.” Mittal claims that Nova Framex can easily give more than 100 repetitions and if handling is better the repetitions can go even up to 200 times .

Optimised for maximum speed

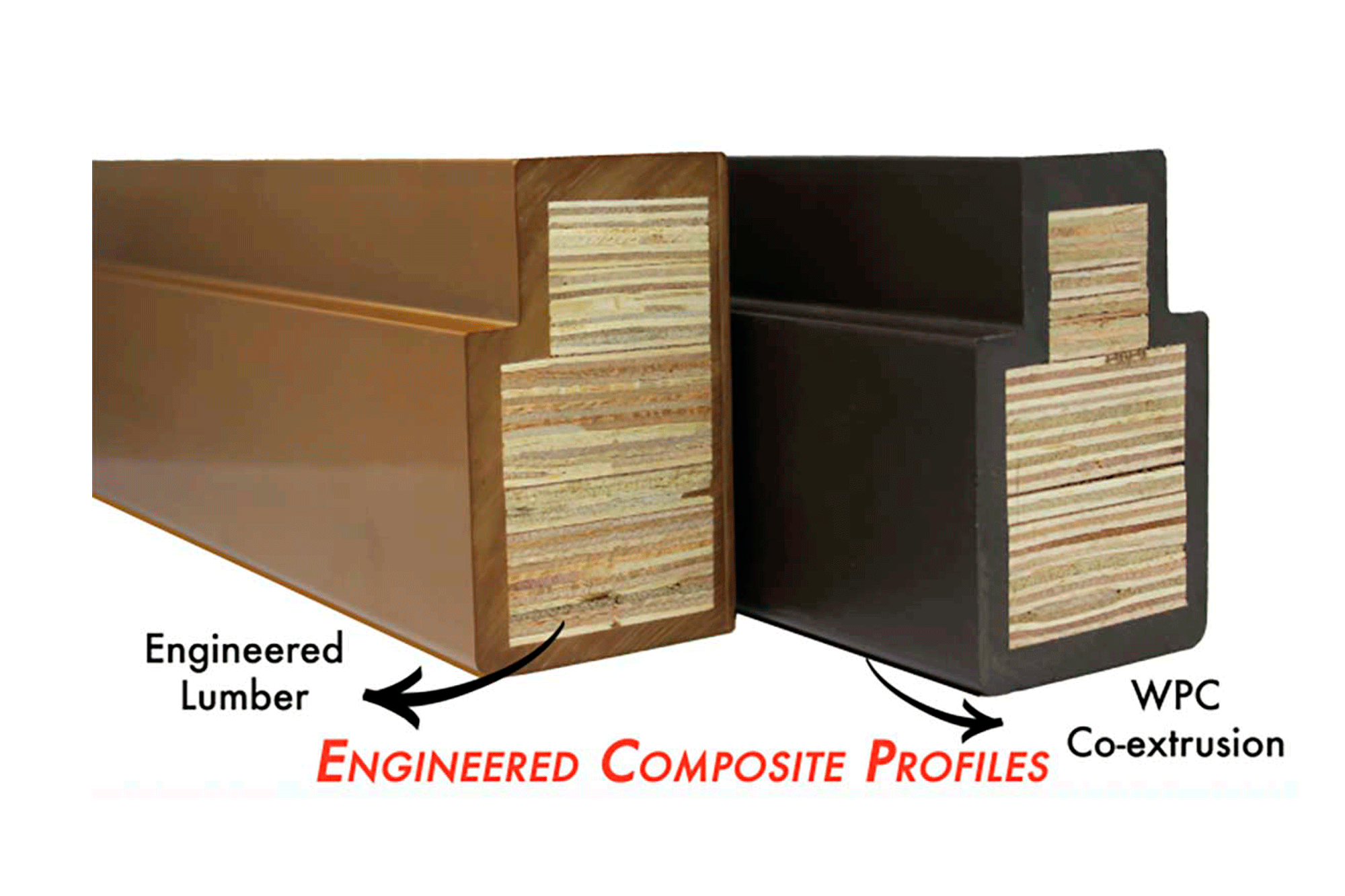

In the tough daily routine on the construction site, speed and efficiency are increasingly becoming the crucial success factor. Sharing the offerings of the company, Kelkar says, “Dokadek 30 is a beam-less, hand-set formwork system designed as a lightweight steel construction faced with a wood/plastic-composite sheet. The system combines the advantages of a panel floor formwork system with those of Dokaflex floor formwork: its 3 square meter panels make it fast in typical zones, yet – because it is easily combined with Dokaflex – it is also quick and flexible in the infill zones. It is erected working from the safety of ground-level without having to walk on the floor formwork. It takes users less effort to engage the panels in the prop heads and tilt them up safely from below, even with taller ceiling heights. Dokadek 30 has only a few panels that need moving; hence it scores with rapid erection and dismantling.”

The Load-bearing tower d3, another product of Doka is a product enhancement of a successful Doka load-bearing system and combines the benefits of existing systems, claims the company. It is is designed for particularly tall shoring heights and high loads and ideally suited for building construction or civil engineering. The system combines speed and efficiency and its flexibility makes it suitable for versatile applications.

“Every construction site goes through its own process. Doka takes an all-encompassing view of the construction sequence and supports the customer through all stages of a construction project – from planning to execution through to completion,” explains Kelkar.

Conclusion

With the new emerging changes in the formwork sector brought into application, there are higher possibilities that they will save the cost and time of construction work. Also as most of the formworks are becoming labour friendly, handling them has become easy. This will no doubt be a boon for the construction sector.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)