VAMEN, tunnel type compact AGV for efficient loading

By Edit Team | April 18, 2022 9:11 am SHARE

VAMEN is an alternative to heavy stationary conveyors or gantries on assembly lines occupying permanent spaces.

Rucha Yantra offer solutions that eliminate complexities in the labor-intensive processes, such as transportation of loads from point ‘A’ to point ‘B’, and storage of goods at shop floor and warehouse. Their Auto Guided Vehicles (AGVs) and Mobile Robots are rugged, and are equipped with advanced Industry 4.0 capabilities to work in manufacturing and commercial setups’ challenging conditions.

Its product range includes, Tugger and Unit Load type AGVs (RAGHAV), Low Height Tunnel Type AGVs (VAMEN), and Human Guided Load carriers (SAEVK). Their AGVs are ‘smarter’ than ever before and come equipped with a host of Industry 4.0 features such as remote performance monitoring, auto loading-unloading accessories, and wireless charging.

Introducing ‘VAMEN’

‘VAMEN’ is a compact tunnel type AGV and another innovative offering from Yantra. It is a low height compact AGV that comes with flatbeds to access locations other AGVs cannot. Its slim structure enables it to reach under the trolley and lift the load easily. VAMEN automatically carries the load from one point to another with automated picking and placing of trolleys and pallets. It is bi-directional, i.e., it can move, both, forward and backward which helps lower cycle time and enable faster movements from point A to point B.

VAMEN has two collision detection sensors – at the front and the rear and 360-degree protection, making it safe to carry material on the factory floor. Additionally, VAMEN is an alternative to heavy stationary conveyors or gantries on assembly lines occupying permanent spaces.

Why VAMEN?

- It is affordable, user friendly and has very low maintenance

- Since it is available in color and natural navigation, the installation requires minimal floor modifications

- Highest safety standards make it suitable to be operated at the shop-floors with much footfall

- Because of its automatic Pick and Place mechanism, VAMEN fully automates the material handling process

- With a built-in weighing scale, it can automatically detect the weight of the load and reduce the cycle time by a considerable amount

Watch this video on our YouTube channel to get a better idea – https://youtu.be/bVWR0ZKDv8g

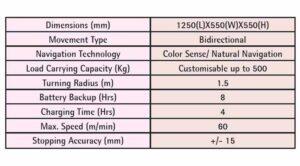

Technical Specifications Although customisable, below are the standard specifications of VAMEN:

Applications VAMEN has a wide range of applications across many sectors, including –

- Automobile

- Pharmaceutical

- Agricultural

- Defense

- Food & Beverage

- Chemical

For more details and enquiries on VAMEN and any of our products,

contact us at: Website: – http://www.yantrallp.com Address: FL-09, Nandadeep Apt, CTS-849/2, Aagarkar Road, S NGR, Pune, Maharashtra. Pin – 411004. Mobile Number: +91 9112237835

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)