Why geosynthetics matter for the future of Indian infra

By Edit Team | June 18, 2018 10:45 am SHARE

The infrastructures need to have long term durability to prevent environmental disaster and land scarcity. Geosynthetics provides such solutions. Here’s an analysis on the importance of geosynthetics for the future of Indian infrastructure.

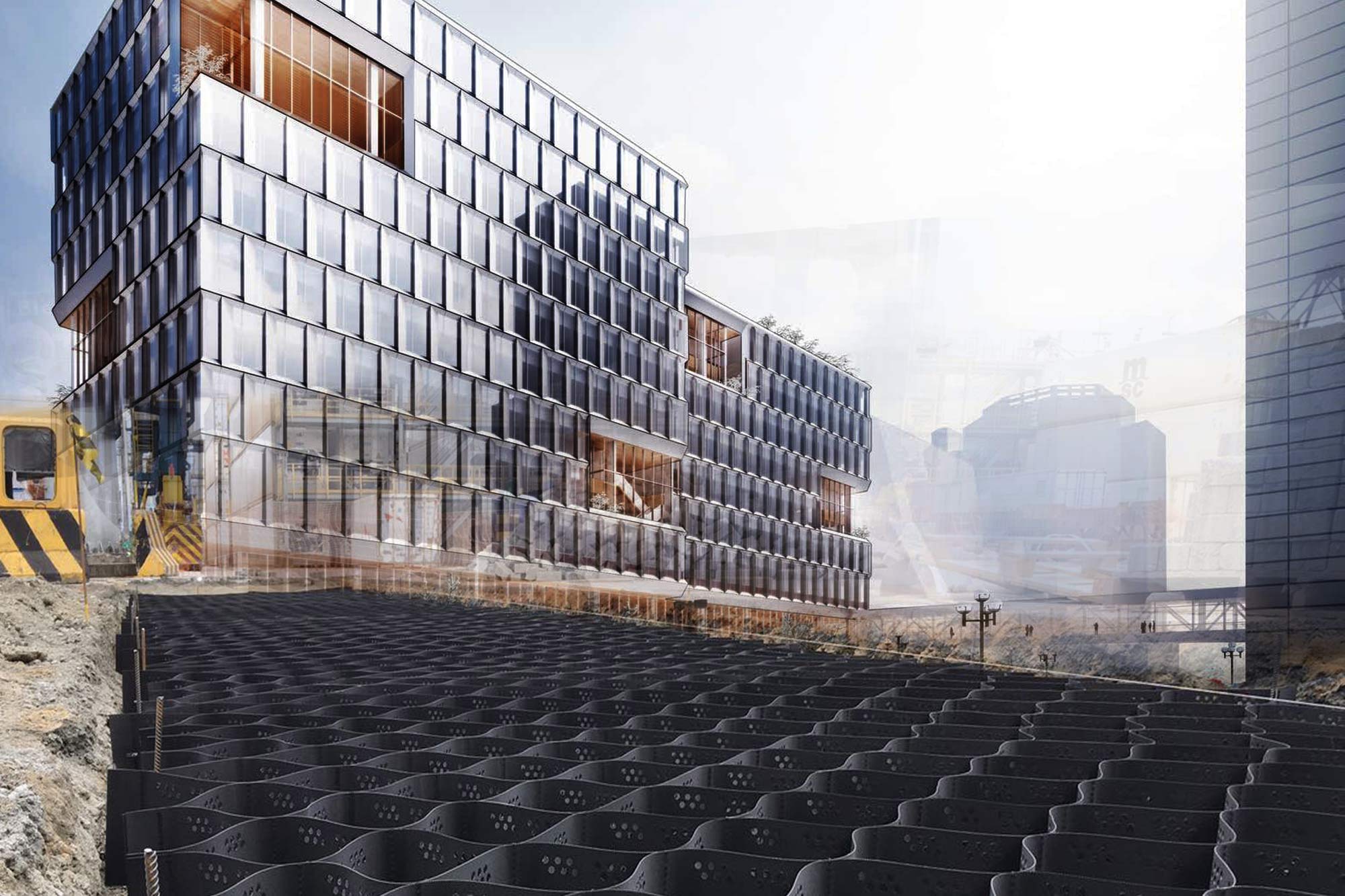

Geosynthetics is mainly a polymeric product thus their polymeric nature makes them appropriate for use in the place where high level of durability is required. Geosynthetics is an integral part of a civil engineering project and is one of the innovations in the field of civil engineering by solving their problems. The need of Geosynthetics in infrastructure sector is increasing continuously. As the burden on natural resources and the dire need for world-class infrastructure increases, the use of geosynthetics in India is crucial. Geosynthetics can replace or minimise the use of scarce and expensive earthen material such as stones.

Significant role of geosynthetics in future

Land has become very expensive in India and geosynthetics can help with that by enabling build of leaner, yet safe structures that are long-lasting. Shahrokh Bagli, Chief Technology Officer, Strata Geosystems India Pvt Ltd informs, “Geosynthetics significantly reduce the capital and maintenance costs, speed up construction time, and are environmentally-friendly (sometimes even providing a green look). Projects involving geosynthetics can be completed with substantially less concrete and steel, and less earth, using reinforced soil walls on highways which reduce transportation and the carbon footprint. To achieve the aggressive infrastructure budget and timelines over the next few years, geosynthetics will play a significant role. Strata Geosystems understands the significance of geosynthetics and aims to provide superior quality products and technically creative solutions in this field.”

Geosynthetics: Need of the hour

For quality and for long term sustainability of the infrastructure modern materials are need of the hour. Geosynthetics is one such material family with proven history worldwide. Be it road, railway or any other civil or engineering discipline. According to Piyush Mankad, CEO, Geotriks, “India is growing and the aspiration of the people of India can be addressed only when we have world class infrastructure. Even to attract global players for the success of ‘Make in India,’ geosynthetics is an absolute must. Hence role of geosynthetics cannot be argued about. It is a need.”

Geosynthetics improve quality and prolong life of infra

Kartik Kanodia, Director, Manas Geo Tech India Pvt Ltd says, “Awareness of modern day techniques like geosynthetics is required to improve the quality of the infrastructure and in turn prolong its life. Geosynthetics is very important for the future of Indian infrastructure because of the benefits it provides.”

Kanodia explains the function of geosynthetics as follows:

• Re-enforcement: Geosynthetics like non-woven geotextile and geogrid, improve the overall strength of the soil. They also prevent lateral spreading of the base, increase the confinement and improve the vertical stress distribution of the sub-grade. The combined benefits can enhance load carrying capacity of the road and railways tracks by well over 50 per cent.

• Separation: Non-woven geotextile helps in keeping the two layers of soil namely subgrade and aggregate, apart; thus preventing mixing and in turn deterioration of their function in the structure. This also prevents contamination of the soil and helps each layer distinctly perform its function.

• Drainage: Non-woven geotextile has a very high permeability and allows water to flow freely along its plane into the side ditches. This function allows adequate liquid flow without soil loss.

• Filtration: Use of geosynthetics allows adequate liquid flow across the plane of the geotextile. The apparent opening size (AOS) allows water to pass freely from the geotextile while preventing soil to pass through the same. This is due to the skilful manufacturing of the non-woven geotextile’s AOS, which is always kept less than the size of the finer soil particles.

Infrastructure segments that will drive growth of geosynthetics

Use of geosynthetics in multiple sectors

Typically, geosynthetics work well where the quality of soil is poor or needs stabilisation. This has led Strata’s to its tagline “No Soil Too Weak” which shows that geosynthetics can be used with almost any soil type. Soil is weak in many regions across India and therefore geosynthetics can be used in a variety of sectors such as roads and highways, landfills, container yards and ports, airports, railways, and canals, and mining. The first vertical landfill in India built by Strata is one of the best examples of its innovation. Bagli explains, “With a developing nation like India, all these segments are rapidly growing. For example, the National Highway Authority of India (NHAI) plans to build 50,000 km of roads worth $250 billion by 2022. Looking at ports, according to a report of the National Transport Development Policy Committee, India’s cargo traffic is expected to reach 1,695 million metric tonnes by 2022. The need for developed ports is on the rise. These few examples show the increased focus that the government has on infrastructure segments, and as a corollary, the need for geosynthetics in India.”

Emphasising on environmental applications

Mankad observes, “Hydro engineering sector like shore protection with the use of geo bags and tubes, water conservation by creating artificial lake and water bodies, transportation engineering sector like road, railway, tunnels and mountain engineering like rockfall protection in the hilly areas should see more usage in days to come. Environmental applications need special emphasis and more regulatory push.”

Key sectors driving growth

According to Kanodia following are the main infrastructure segments that will drive growth of geosynthetics:

• Ports: Indian ports handled 1.135 MT of traffic in 2017-18, Indian ports are rapidly increasing and non-woven geotextile or geogrids are widely used for soil stabilisation, geotextile or geogrid are placed below the subgrade to improve the CBR and load bearing capacity of the soil enabling it to handle high axle load.

• Roads: India has a road network of 5,603,293 kms which is the second largest road network in the world. Geotextile or geogrid is widely used for re-enforcement, filtration and separation.

• Tunnels: Non-woven geotextile and geomembrane are used in tunnel lining and provide excellent drainage of water into the side ditches.

• Railways: Geotextile along with geogrid is widely used under railway tracks to provide stabilisation and re-enforcement.

Geosynthetics significantly reduce the capital and maintenance costs, speed up construction time and are environmentally-friendly.

Shahrokh Bagli, Chief Technology Officer, Strata Geosystems India Pvt Ltd

To attract global players for the success of ‘Make in India,’ geosynthetics is an absolute must. Hence role of Geosynthetics cannot be argued about. It is a requirement and a need.

Piyush Mankad, CEO, Geotriks

Awareness of modern day techniques like geosynthetics is required to improve the quality of the infrastructure and in turn prolong its life.

Kartik Kanodia, Director, Manas Geo Tech India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.