Crushing it with eco-friendly innovations

By Staff Report | August 13, 2024 2:49 pm SHARE

Keestrack’s crushers combine high performance with sustainable innovation, achieving superior product morphology and efficiency. With state-of-the-art features, including energy-efficient drives and advanced dust suppression systems, Keestrack boosts productivity and minimises environmental impact.

What features make Keestrack crushers excel in product morphology, high reduction ratios, and operational efficiency?

Our crushers are engineered primarily to achieve superior product morphology and high reduction ratios. These features are critical for maximising productivity and operational efficiency in demanding environments.

Our crushers utilise state-of-the-art crushing mechanisms, including jaw, cone, and impact crushers. These advanced technologies facilitate precise material size reduction, ensuring consistent particle size distribution and output quality. The design and operational parameters of our crushers are meticulously calibrated to produce optimal product shapes. This is particularly essential for applications such as concrete aggregate production, where the shape and gradation of the particles significantly impact the final product’s performance characteristics.

Our equipment achieves high reduction ratios by employing innovative crushing techniques. This capability effectively transforms large feed sizes into fine, uniform output, thereby enhancing overall process efficiency. Our commitment to quality ensures that our crushers maintain unparalleled performance even under the most challenging conditions, typical of mining and large-scale construction projects. The robust construction and advanced control systems enable continuous operation, minimising downtime and ensuring that project timelines and productivity goals are consistently met.

How does Keestrack enhance operational flexibility and mobility in its machines?

All Keestrack machines are engineered for ultimate operational flexibility. Their compact design and mobility enable easy transportation and swift setup on diverse job sites. For instance, our equipment has been successfully deployed in remote mining sites in Rajasthan, the North Eastern parts of India, and large-scale infrastructure projects nationwide. The ability to quickly relocate and configure our crushers allows operators to maximise productivity by minimising downtime and optimising material processing directly at the source.

Which features and technologies does Keestrack use to enhance the sustainability and efficiency of its machines?

Our machines are designed to minimise environmental impact through several key features. We incorporate advanced dust suppression systems to manage dust and particulate emissions, utilise energy-efficient drive technologies, and equip our machines with Tier 4 Final / Stage V compliant engines to meet stringent emission standards.

We offer diesel-electric and zero-drive options that enhance fuel efficiency and significantly reduce the carbon footprint. Our practices support clients in achieving their environmental goals while maintaining high operational standards across industries like urban mining, quarrying, recycling, and aggregates.

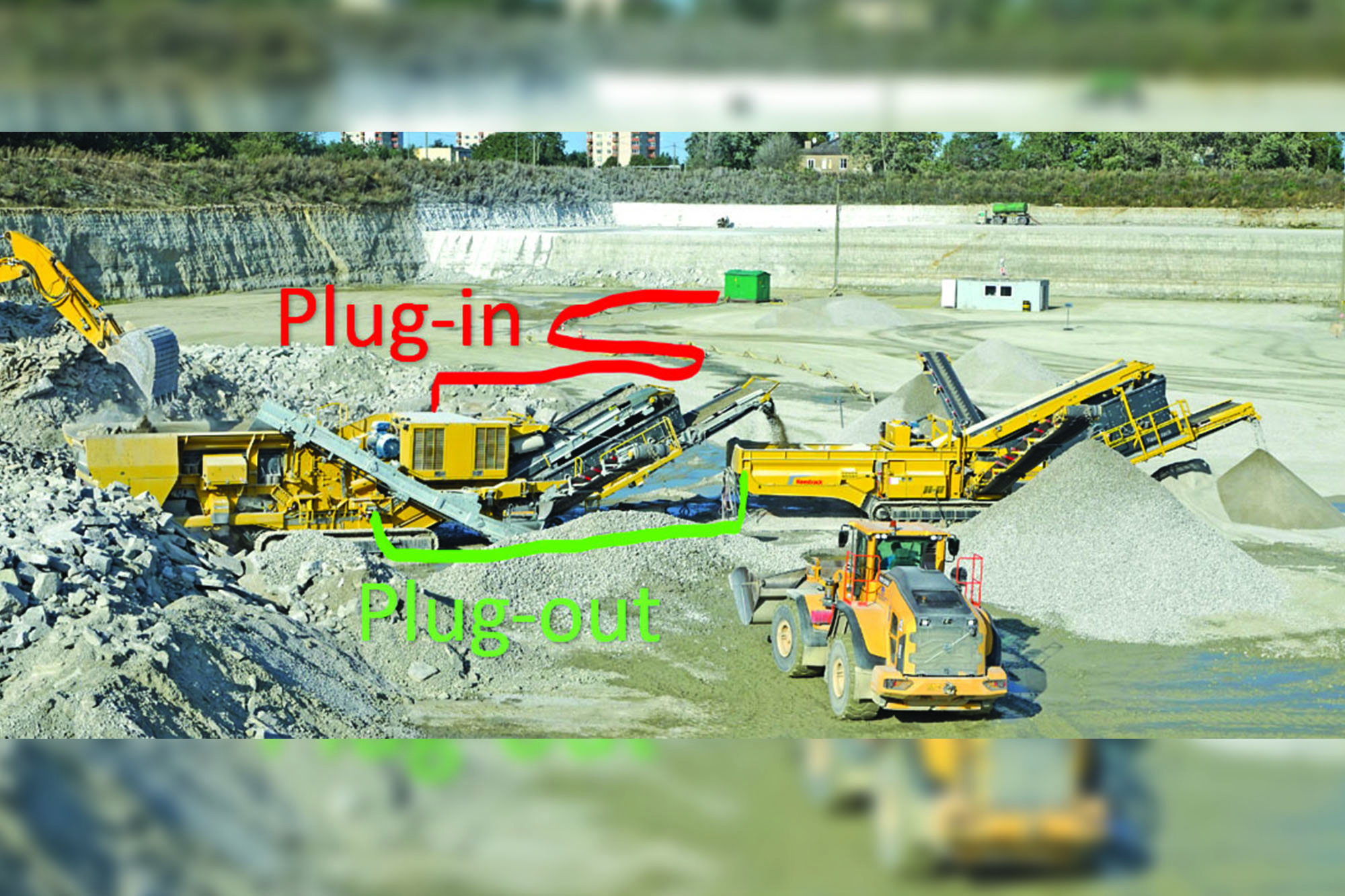

Our innovation extends to drive systems, transitioning from hydraulic to electric and zero-emission drives, which are the most efficient and environmentally friendly. If no electric plug-in is available, users can choose between their generator sets or Keestrack’s engine/gen-set units. Diesel-electric plants can save up to 40% in fuel, and hybrid screens and stackers can reduce fuel consumption by up to 70% when powered by an electric crusher’s plug-out supply. Connecting to the grid also helps lower operational and maintenance costs based on local electricity prices.

What strategies does Keestrack use to provide reliable aftermarket support for equipment in remote locations?

Recognising the challenges of maintaining equipment in remote locations, we have implemented comprehensive strategies to ensure reliable and timely aftermarket support. Our network of skilled technicians, strategically located dealers, and resident engineers across India ensures quick response times.

Our advanced Keestrack-er remote monitoring system provides real-time diagnostics, allowing for proactive maintenance and minimising downtime. We also offer extensive training programs to equip operators with the necessary skills to manage routine maintenance effectively.

Could you please explain how the Neemrana manufacturing facility has impacted Keestrack’s product development and market presence in India?

Since establishing our state-of-the-art manufacturing facility in Neemrana in 2021, we have experienced substantial growth in product development and market presence in India. This local production capability has allowed us to tailor our equipment to meet the specific needs of the Indian market, resulting in increased demand and application versatility.

The improved production efficiency has shortened lead times, enabling us to respond swiftly to market demands. We have observed a significant increase in projects utilising our crushers, ranging from urban construction to rural infrastructure development.

Please elucidate your approach to innovation, localisation, and sustainability.

We believe innovation should simplify machinery, reducing operational and maintenance costs to maximise uptime. Our products incorporate the latest technology and best-in-class features to achieve the lowest operational costs.

We manufacture machines at our Neemrana facility, which has achieved approximately 80 percent localisation. This facility also serves as our global supply base, with plans to reach 100 percent localisation. Localising wear and maintenance parts ensures cost competitiveness and provides immediate support.

In addition to advancing machinery, we implement several initiatives to enhance environmental sustainability. We invest in R&D to improve energy efficiency and reduce emissions across our product range. By optimising engine performance and using intelligent control systems, we minimise the carbon footprint of our machines.

We also promote alternative fuels and electric power options, focusing on zero-emission electric models contributing to cleaner work environments. Our commitment extends to recycling and waste management practices, aiming to reduce the environmental impact of our manufacturing processes.

Collaborating with customers, industry partners, and government bodies, we raise awareness about environmental issues and promote sustainable practices in the construction and mining sectors. Our continuous innovation reflects our dedication to environmental stewardship, ensuring our products and operations contribute positively to the environment while maintaining high efficiency and performance standards.

For more information, visit: https://etrackcrushers.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.