Accelerating construction projects with prefab technology

By Staff Report | October 24, 2024 2:57 pm SHARE

Tata Steel Nest-In leads the prefab construction industry with innovative, sustainable solutions like 3D Volumetric and LGSF, offering faster, eco-friendly construction across sectors from healthcare to industrial applications.

What are the latest trends in prefabricated and modular construction that Tata Steel Nest-In is observing in the industry?

To remain relevant today, staying on top of ever-changing trends is critical. The prefab construction market is thriving, with sophisticated technologies such as 3D volumetric and hybrid construction—more complex types of modular construction that require the vertical stacking of ready-to-use modular parts—gaining traction alongside LGSF and other modular approaches.

Overall, LGSF and modular construction technologies are always being researched and developed to improve their efficiency, sustainability, and adaptability to different applications. We have been involved in various corporate social responsibility efforts, including constructing multispecialty hospitals and cutting-edge educational institutions using cutting-edge technology.

Can you discuss the innovations in materials used in your prefabricated solutions, particularly regarding durability and sustainability?

Quality materials are key to the Nest-In construction process, as evidenced by the recent achievement of ISO 9001:2015 accreditation, a worldwide recognised standard for Quality Management Systems (QMS). This international certification certifies our dedication to quality and assures that our prefabricated construction solutions adhere to the highest requirements. Customers can be confident that the solutions they obtain from us adhere to internationally recognised quality management methods. This certification demonstrates our commitment to client satisfaction and continual improvement in all business areas.

Our prefabricated solutions solely contain high-quality Tata steel. We employ fibre-gypsum and cement boards and insulation materials such as mineral wool as supporting materials. Tata steel is extremely robust, rugged, rust-resistant, and solid, making it suitable for our prefab solutions, built-in unstable terrains, or places prone to extreme weather events such as floods and earthquakes.

Our prefabrication procedures are intended to be as sustainable as feasible. For example, we use 48 percent less freshwater than RCC construction methods because we only use cement in the base. Our procedures are subject to stringent quality audits and must meet the highest international sustainability and efficiency standards.

The LGSF Nest-In solution is touted for its speed and efficiency. Can you elaborate on the advantages of Light Gauge Steel Frame (LGSF) construction over traditional methods?

We’ve used LGSF to complete various large-scale projects. Because of its adaptability and durability, it is a popular building method in prefabrication enterprises. It offers various advantages over traditional construction methods, the most prominent of which is its speed, which is more than twice as fast. This is due to our efficient operations: the LGSF framework is constructed of prefabricated steel components built in a factory. These components are designed to be placed immediately on-site, aligning with the customer’s vision and needs. Major work is done offsite, while assembly is done on-site, so rain/weather does not interfere with schedules. This differs from the typical construction process, in which raw materials are not precisely manufactured, bad weather causes construction delays on-site, and installation or execution falls short.

Another advantage is the ability to sustain operations. As I previously stated, our prefabrication technologies use 48 percent less freshwater, and 65 percent fewer materials, and have a 53 percent lower greenhouse gas effect than typical construction methods. We only need a little transportation or heavy machinery because we only go to the site to dig the foundation and move the prefabricated components. We want a small team of specialists adept at assembling and installing prefabricated structures, emphasising safety and less on-site labour to avoid on-site accidents.

Another significant benefit is our exceptional adaptability to difficult terrains. Prefabricated construction is the solution for situations where traditional construction methods are difficult to use, such as steep terrain, mining regions, and areas prone to earthquakes, vibrations, floods, and high winds. Our prefab solutions are built to withstand harsh conditions, and their lightweight design makes installation in mountainous and unstable terrain simple and hassle-free.

How do the modular portable cabins cater to the diverse needs of industries such as manufacturing and construction?

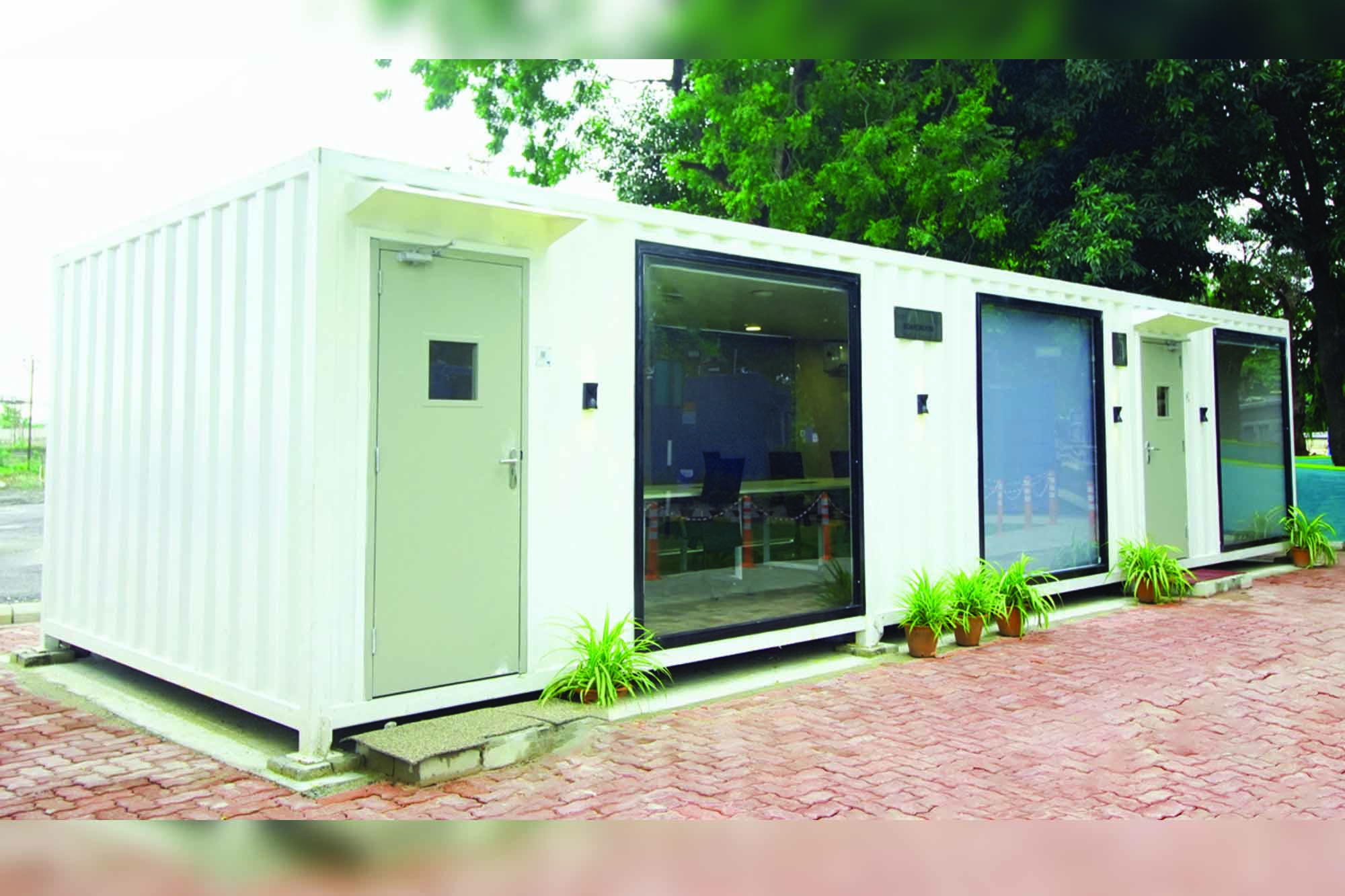

Modular cabins are designed to be versatile, flexible, and adaptable. They are completely plug-and-play, with just basic plumbing and electricals needing to be fixed on-site and the remainder of the cabin, including the inside, being manufactured offsite. They are the right answer for the following locations on a building site or manufacturing: a site office, creche, boardroom, workers’ rest shelter, canteen, toilet blocks, and conference room. These modular blocks can be customised for their specific application and expanded by adding modular blocks to accommodate larger numbers of people, more rooms, more restrooms, and so on.

Can you discuss the key features of your specialised COVID-19 offerings, such as isolation and quarantine cabins?

We were honoured to help our country tackle the COVID-19 pandemic with our prefabricated healthcare solutions. Our COVID-19 isolation and quarantine cells were created with cutting-edge medical facilities to provide prompt and efficient care. We have created 23 cabins for a 96-bed modular hospital in Faridabad, including 16 interconnecting patient cubicles, six washrooms, and one doctors’ utility room. Each patient cabin had two air conditioners, medical furnishings, and six medical beds, each with an oxygen pipeline. Offsite production and on-site quick plug-and-play resulted in a more than four times faster ready healthcare facility than conventional procedures.

For more information, visit: https://www.tatasteel.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)