ArcelorMittal and HP collabs to drive steel additive manufacturing

By Staff Report | November 12, 2024 7:09 pm SHARE

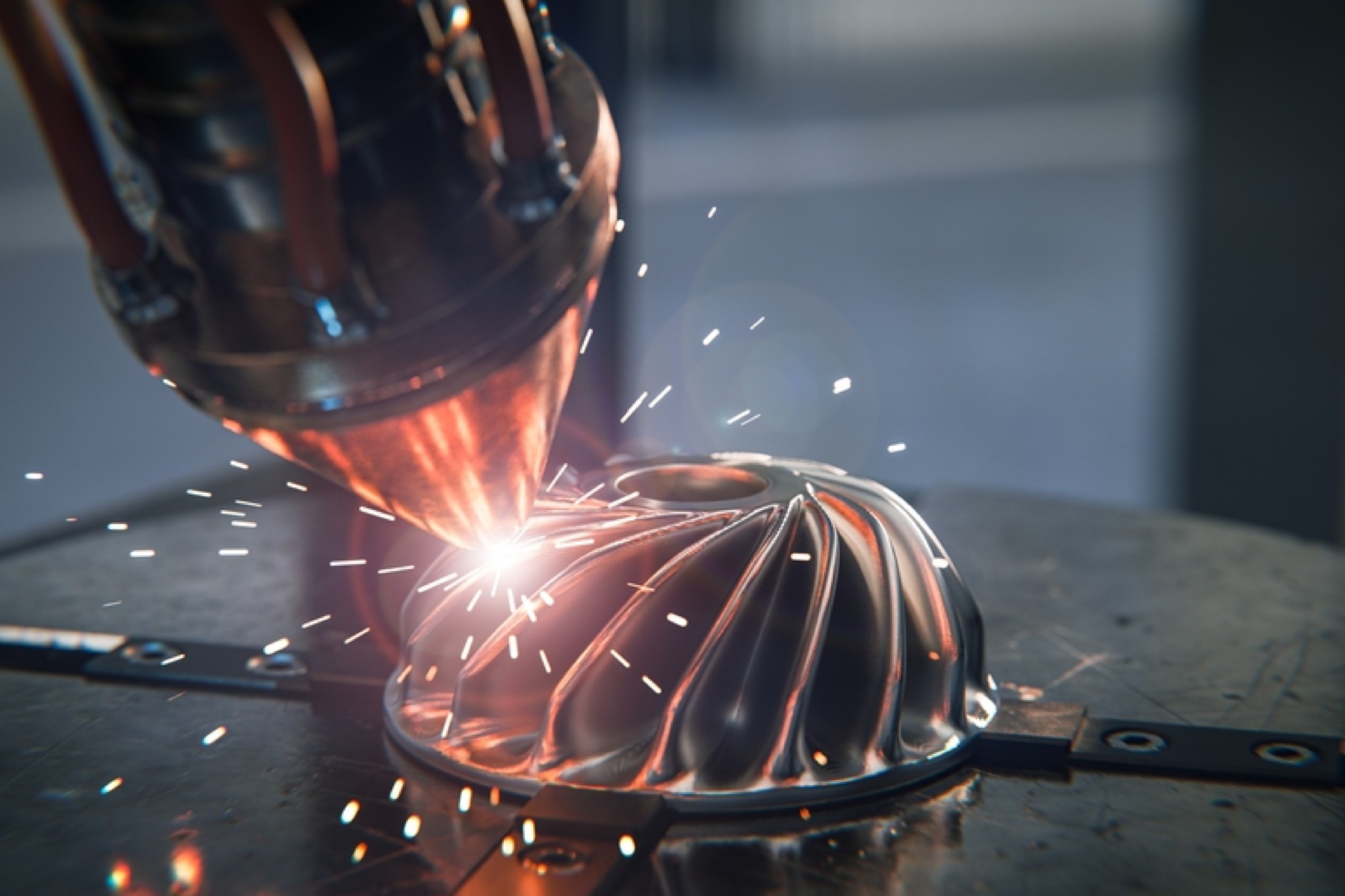

ArcelorMittal and HP have teamed up to transform steel additive manufacturing. They combine HP’s Metal Jet S100 technology with ArcelorMittal’s expertise to develop innovative, sustainable, and cost-effective solutions for various sectors.

ArcelorMittal, a global leader in sustainable steel solutions, and HP, a well-known printing firm with substantial experience in additive manufacturing, are happy to announce a strategic partnership to improve steel additive manufacturing. This collaboration is a critical step towards developing novel solutions that will impact the future of additive manufacturing.

ArcelorMittal recognises HP’s technical expertise by utilising their cutting-edge Metal Jet S100 technology for steel additive manufacturing. This adoption demonstrates ArcelorMittal’s dedication to using modern technology to improve its manufacturing capabilities.

HP acknowledges ArcelorMittal with good results with their steel powders, demonstrating the robustness of binder jetting technology. These powders demonstrated instant good performance without requiring any changes to printing conditions, showcasing the two firms’ synergy.

The collaboration intends to advance steel additive manufacturing by combining HP’s printing and existing production knowledge with ArcelorMittal’s leadership in sustainable steel solutions.

The collaboration will focus on the following key pillars:

- Lower Cost per Part: Taking a comprehensive strategy to unlocking a wide range of accessible parts for 3D printing, particularly in the automotive industry.

- Extend Material Options: Creating steels with unparalleled qualities that are impossible to achieve using traditional manufacturing methods.

The proposed working model entails HP and ArcelorMittal collaborating to bring new steel solutions to a sufficient Technology Readiness Level (TRL), and then leveraging ArcelorMittal Research Centre for breakthrough applications as an incubator for new applications developed in collaboration with customers, saving them the initial investment to evaluate and qualify the technology until the process can be transferred to a contract manufacturer for final industrialisation.

This partnership is a huge step forward for steel additive manufacturing. It brings together the skills of two industry giants to promote innovation and provide high-quality, sustainable solutions.

Aubin Defer, Chief Marketing Officer at ArcelorMittal Powders, says, “We are thrilled to collaborate with HP in advancing steel additive manufacturing. This collaboration leverages our combined expertise to develop innovative solutions to drive the industry forward. The promising results of our steel powders with HP’s binder jetting technology are a testament to the potential of this partnership.”

Alexandre Tartas, Global Leader of Metals Sales & Go To Market at HP, adds, “We are excited to join forces with ArcelorMittal to push the boundaries of steel additive manufacturing. This collaboration will enable us to leverage our technical expertise and ArcelorMittal’s leadership in sustainable steel solutions to create groundbreaking advancements in the industry. Combining the steel expertise of ArcelorMittal and HP Additive Manufacturing positioning in high volume production offers a unique value proposition for the manufacturing industry.”

For more information, visit: https://corporate.arcelormittal.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)