Bentley’s ProConcrete V8i flexibility in rebar detailing

By Edit Team | January 30, 2015 6:54 am SHARE

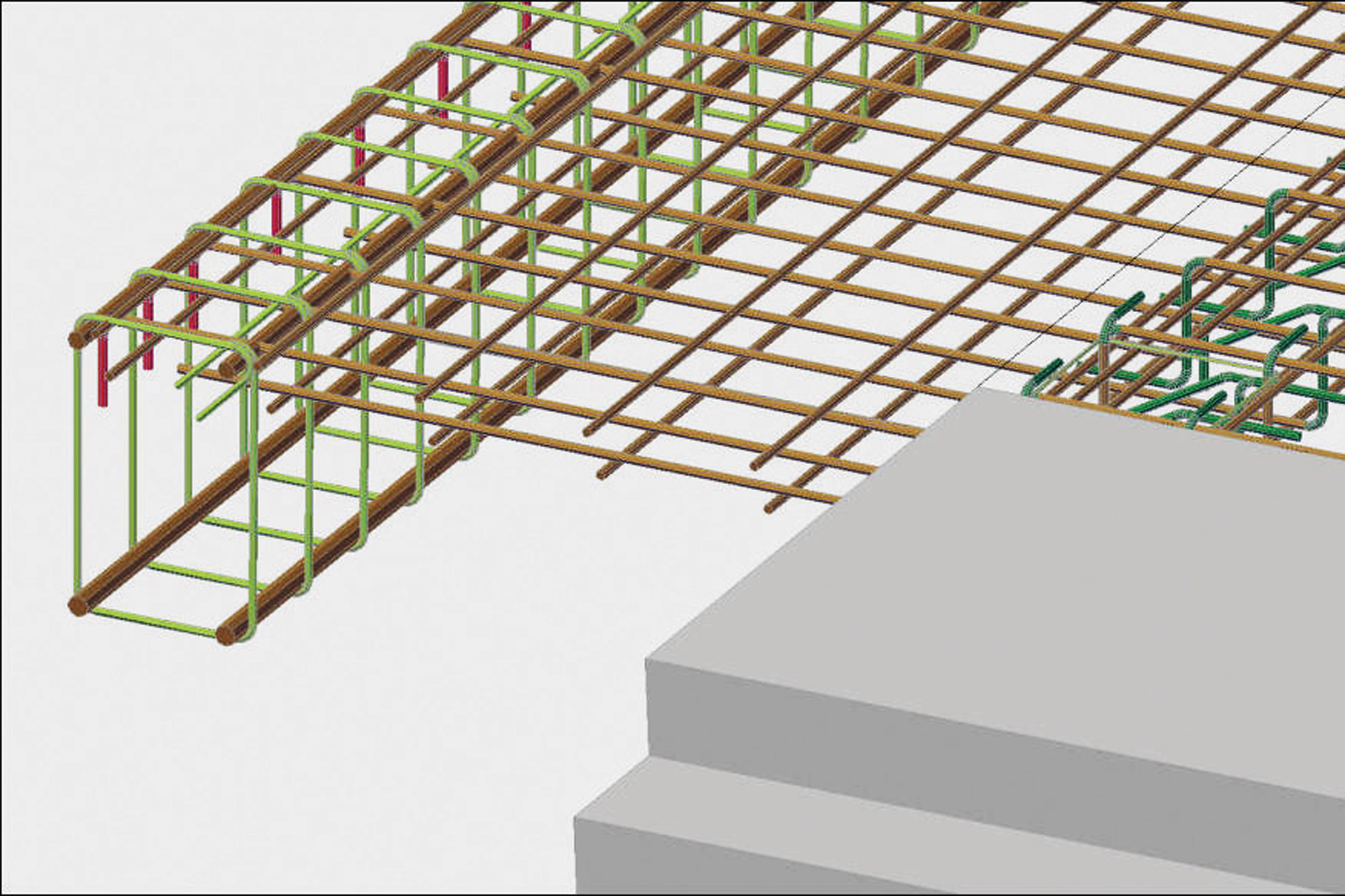

Structural Engineers to gain enhanced efficiency in reinforced concrete projects with coming addition of rebar drawing automation to Bentley’s ProConcrete.

ProConcrete V8i (SELECTseries 7), to be launched in 2015, will include Bentley’s rebar drawing automation technology, resulting in a cutting-edge BIM offering for reinforced concrete projects worldwide.

Bentley Partner Scott D. Leib, President and CEO, Applied Systems Associates, Inc., said, “Efficient rebar and concrete drawing production for both detailers and designers has long been the biggest challenge in the adoption of 3D modelling. By intelligently automating the most time-consuming tasks of drawing production – from hidden bar rendering to special purpose symbolization and automated scheduling – the concrete design and detailing industry takes a big step forward in productivity. We are also excited by the future. As we continue to integrate the 2D modelling capabilities and cross section drawing templates from Bentley Rebar and aSa’s own 2D detailing application into ProConcrete, we open up a world of new possibilities for users’ comfortable working in 2D or 3D.”

Bentley Rebar has long been Bentley’s signature rebar product, but its strength has been its provision of a 2D workflow. ProConcrete is Bentley’s 3D rebar and concrete product. Seamlessly integrating the two technologies in ProConcrete V8i (SELECTseries 7) provides users maximum flexibility in rebar detailing. Bentley Rebar’s dynamic concrete drawing, labelling, and scheduling engine working in concert with ProConcrete’s 3D modelling capabilities will deliver integrated and automated drawing production, enhancing user efficiency.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)