Bison Panels: The preferred choice for customers

By Edit Team | February 15, 2018 9:02 am SHARE

The success stories on Bison panels highlight diverse applications and unique advantages.

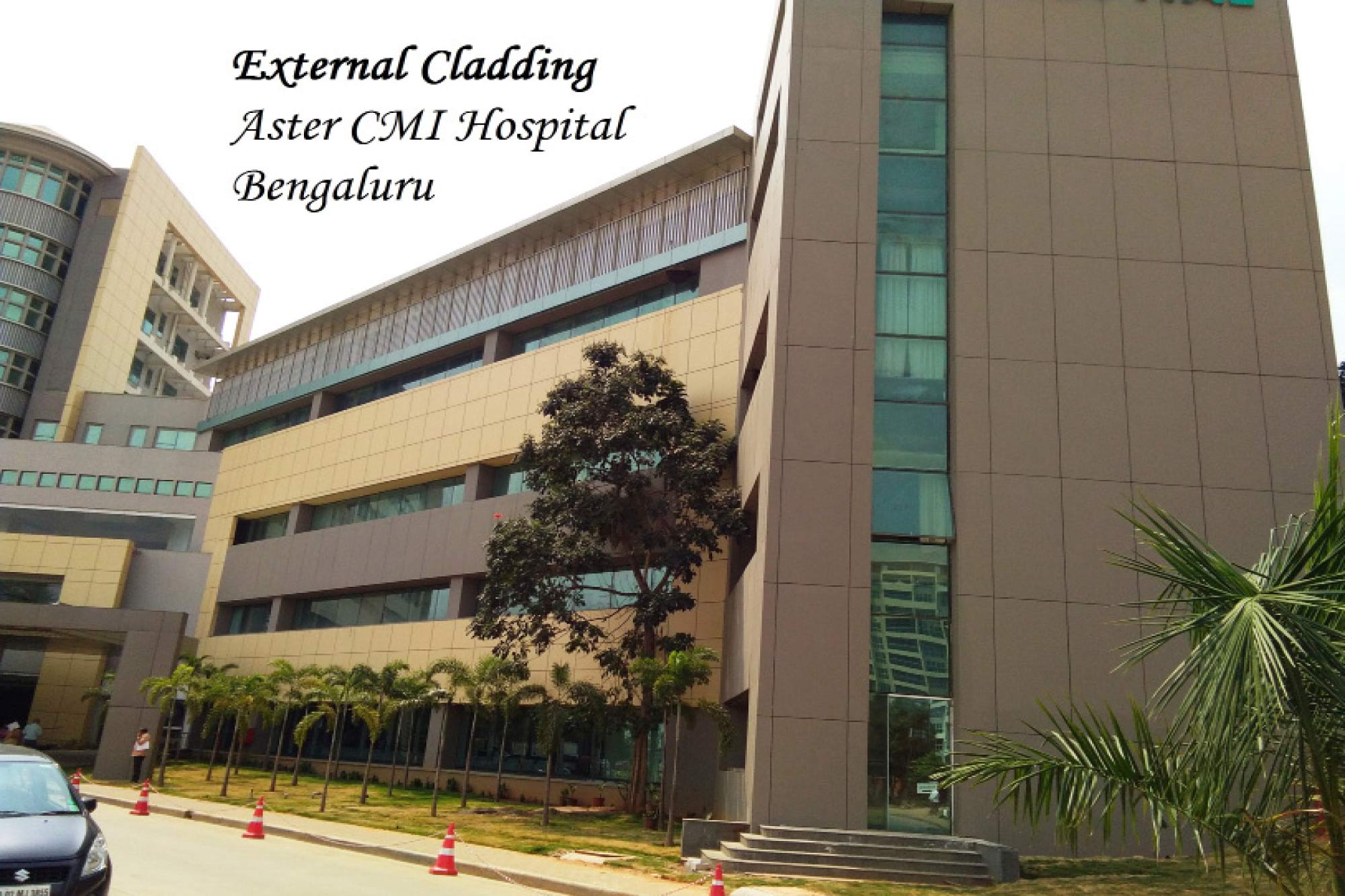

Aster CMI Hospital prefers Bison panels for external wall cladding

Aster CMI Hospital in Bangalore is a trusted name in healthcare. When the need for external wall cladding arose, they chose to go with a trusted brand with an excellent track record. While the initial preference was for ACP boards, the versatility of Bison boards coupled with its durability was enough to convince them.

The look of trust

Hospitals are places that inspire immense trust in their patients and families. Arun Nalapat Architects, the firm helping to design their new building, were starkly aware of this. When the proposal to choose external cladding came to their table, they wanted a sleek, sophisticated and elegant option that was also durable and easy to maintain. To match the colour specifications, Bison Panels were painted with a lacquer of choice.

Fulfilling many needs (sub-para)

Aster CMI Hospital is situated on the very busy New Airport Road, National Highway 7. By choosing an external cladding material, Arun Nalapat Architects wanted to not only add aesthetic appeal but also to serve a greater purpose- provide soundproofing and insulation to the patients inside. The use of Bison boards of 12 mm thickness ensured that this brief is met. Moreover, since the external cladding cannot be cleaned every other day, the usage of Bison boards that are dust resistance makes maintenance easy.

A fulfilling experience

Bison Panels stand for durability, strength and serving a purpose. That they fulfill all of these promises is witnessed in the fact that a renowned hospital has adopted these panels for their use. In future projects, the client is looking forward to using Bison Panels in a variety of different applications such as interiors and false ceilings. Again, in their decades of service, the Bison Panel has proven that it is the best option for a variety of construction needs.

Key challenges

- Matching the colour specifications for the external cladding was very important to keep the panel in line with the architect’s vision.

- Since Bison Panels were being used by the client for the first time, a few operational difficulties arose and were promptly addressed.

Highlights

- Soundproofing was the topmost priority for the hospital, and this was successfully achieved using 12 mm boards.

- Arun Nalapat Architects specified a set of safety and resistance guidelines, and Bison Panels were able to match all of these specifications.

- Being dust resistant, regular painting alone is sufficient to maintain the panels for at least 25 years. With cost differences of close to 45 per cent as compared to traditional external cladding material, Bison Panels are a cost-effective solution that can be put to diverse applications.

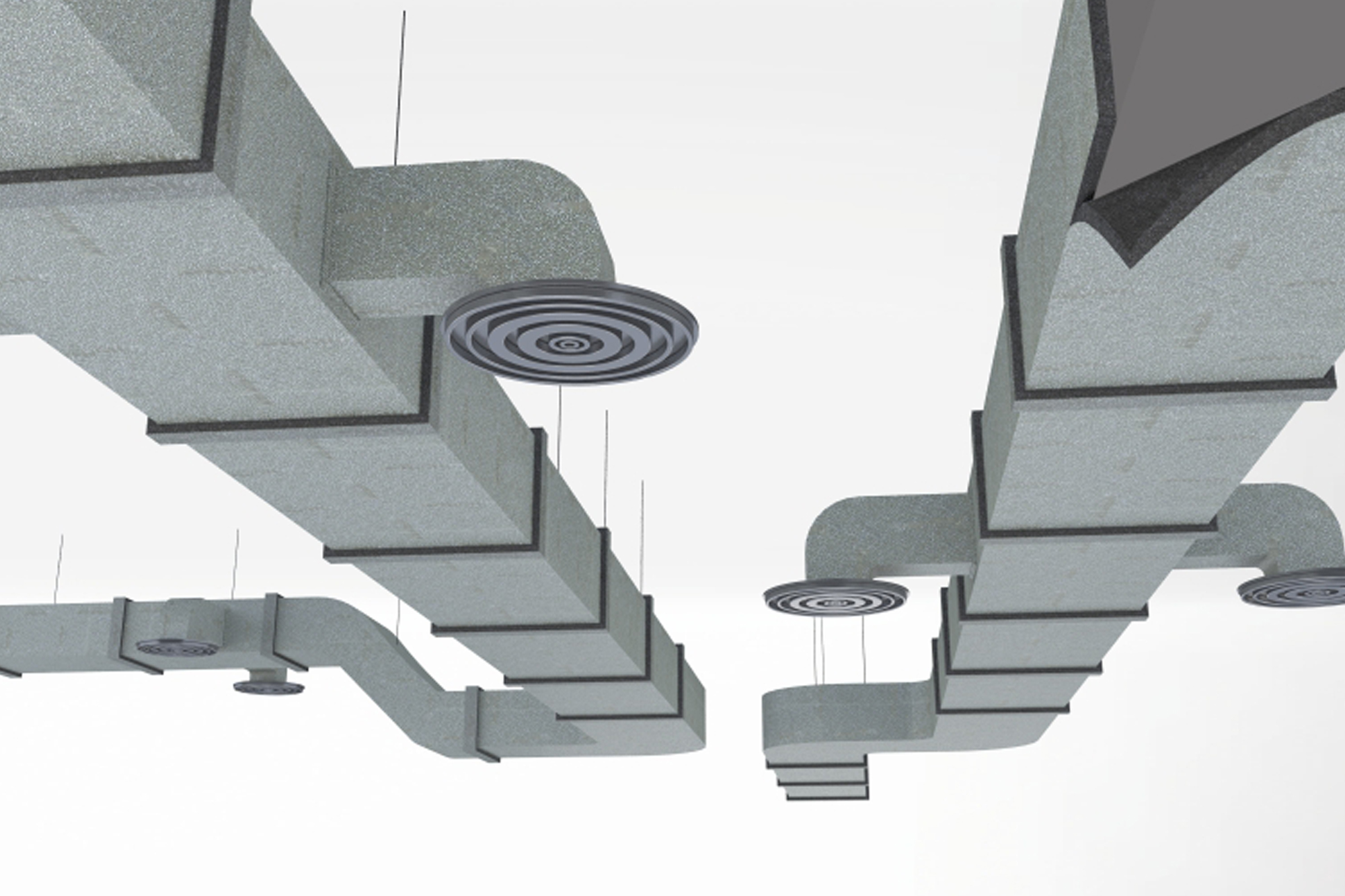

Bison panels used successfully in L&Ts office space

In yet another success story for Bison Panels, Larsen & Toubro India used these cement bonded particle boards for their new office interiors, exteriors, wall panelling and for false ceilings. Keeping in mind the scope of the project, fabricators were able to complete the project promptly and on time.

Versatile requirements

At the very outset, the client made it clear that they wish to use Bison Panels for most internal and external applications. They also had specific fire safety, water resistance and soundproofing norms

Diverse applications

Bison Panels proved to be a cost-effective alternative to the Aluminium Composite Panel (ACP) sheets that are used most often for false ceilings. Apart from the ceilings, the Bison boards were also used for wall panelling, Interior aesthetic design as well as external wall claddings. Boards of different thickness specifications and designs were used for each of these applications.

At the forefront of innovation

Since the building’s interiors were already in place, it was essential to make the Bison Panels a part of the original design such that they stand out aesthetically and serve their purpose too. Joint gaps were thus left in place, and Bison boards were strategically placed to give an appearance of blending in with the surroundings.

Happy clients

It was a significant move on the client’s part to choose to use Bison Panels for all external and internal applications. This would be their first experience with cement bonded particle boards. However, with on-time delivery and seamless execution, as well as by addressing operational issues soon as they cropped up. L&T is one happy customer. Product durability is another factor that clients consider very important and with regular painting, durability for the next twenty-five years is assured.

L&T is now preparing to use Bison Panels in their own property constructions- the highest accolade the panels could receive from a client.

Key challenges

- Fabricators had some trouble initially using Bison Panels in place of ACP for false ceilings. However, with proactive involvement, this was resolved soon.

- Since the client is already in the infrastructure space, highest standards of execution were of paramount importance.

Highlights

- In spite of using Bison Panels for the first time, fabricators found their flexibility of use quite beneficial.

- Bison Panels are able to comply with all noise, fire safety and pollution control standards, expected by the client.

- With a durability of over two decades, Bison Panels can stand the test of time even with regular use.

- Compared to available market alternatives, Bison Panels offered a cost saving of 45 per cent on the project, making them a feasible alternative for extensive use.

Bison is both fire and moisture resistant; possess superior termite and weather resistance

Bison Panel is a cement bonded particle board that is fire, weather, and termite resistant a good sound insulating material, dimensionally stable, possesses a smooth surface with wood workability and is chemically stable. Tested in accordance with BS 476 – Fire test on building materials and structures. Part 6, 7 – it is classified as a class ‘O’ building board with class I surface spread of flame. The board has been subjected to many cycles of soaking, freezing, and heating without any sign of disintegration. Due to mineralisation of wood particles by cement, Bison is resistant to termite and vermin attack. It does not support fungus growth. Even untreated samples exposed to contact with the ground surface have shown no signs of rot or decay. Airborne sound reduction varies between 30 and 37 db for the frequency range of 100 – 3150 Hz according to thickness of Bison Panel It can also be drilled, sawn, and sanded with normal wood working tools, and can be fixed using screws and nails.

Certifications

Bison panels conform to IS 14276. Bison panels are green building material and eco-friendly, certified by IGBC and GRIHA. The products are radio actively neutral. Bison boards are T.U.V –Singapore- certified for Fire propagation and surface spread of flame, tested by C.P.R.I for Heat release rate. Our boards are tested for Load bearing strength by J.N.T.U Hyderabad and Civil Aid Techno-clinic, fire resistance by Bodycote Warrington, England, thermal conductivity by Isolloyd Engineering Technologies Limited, Himachal Pradesh, Sound Transmission Class value at Prasar Bharathi, New Delhi and Impact test by National Test House, Kolkata.

For more details, visit NCL Industries at www.nclind.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)