Concrete floor maintenance and repair are essential to prolonging the life of buildings. Zara P Care’s CRP-FLR solution offers quick and comprehensive concrete restoration within four hours.

Concrete floor maintenance and repair

With the vast number of concrete structures that surround us every day, it’s easy to take concrete for granted and forget how it enables us to live our lives in our evolving urban landscape. Just like us, concrete needs maintenance. It is affected by the stress and strain of everyday life. Concrete deterioration can occur due to corrosion, structural damage, water infiltration, seismic activity, or many other reasons. Concrete floors are vital parts of any structure that are most exposed to heavy traffic, fluctuating temperatures, impact loads, abrasion, and friction, all of which gradually damage the floor over time.

Concreting and flooring lifecycle

The floor’s life depends on the type of material used, exposure conditions, frequency of loading, and other factors. The average floor without a protective coating can last 20–30 years, while the average concrete structure can last 50–100 years, meaning every building will need at least one-floor replacement or repair. Therefore, concrete floor repairs are inevitable and indispensable. Repairs restore or maintain existing equipment’s usability, often contributing to the extension of its expected life and increasing the sustainability of building resources.

Innovating concrete products and solutions

Currently, the various floor repair methods available consume a lot of time to repair and prepare the floor. The average time required for various MNC products is 6 to 7 days. This is the cause that forced Zara P Care to research and developed a product that could solve this problem in one day so that the floor could be used on the same day to minimise the loss of time, money, and commitment.

Inventing a CRP-FLR solution for concrete restoration and rehabilitation

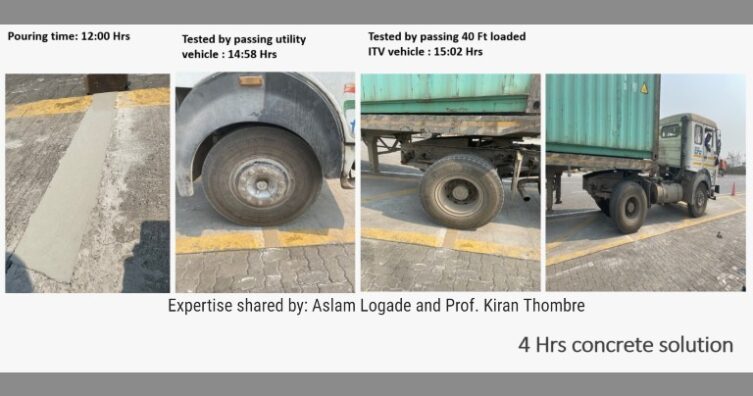

A dedicated team of researchers and years of hands-on experience have enabled Zara P Care to develop a fully comprehensive CRP-FLR solution for restoring and rehabilitating concrete floors within 4 hours. Concrete Reinforced Putty for Floors (CRP-FLR) is a self-levelling, two-component product specially developed to repair cracks and damage in floors and roofs. The magical properties of the product allow it to harden within 4 to 5 hours, and the surface is ready for use with full load capacity. The abrasion resistance of the product has already been verified and tested in more than 50 places, which is better than the real floor material.

Concrete adhesion and load capacity

The compressibility and ductility of the product are also good, and it can withstand traffic loads in tonnes and does not show any cracks due to its better elasticity. CRP-FLR also has better adhesion to concrete. The product can withstand temperatures over 3000 °C. In short, CRP-FLR is a high-strength, superfluid, shrinkage-compensated micro-concrete developed to withstand high temperatures. The following case study verifies the quality of the product. Our prominent areas for services are the warehouse, RTG tracks in the port area, production shop floor area, etc.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.