Dewatering solutions for the mining industry

By Staff Report | November 19, 2024 12:39 pm SHARE

With its cutting-edge dewatering panels and conveyor cleaning systems, Jaws Tech is revolutionising mineral processing with environmentally friendly methods while increasing efficiency.

What products did you showcase at IMME 2024?

We specialise in wear-resistant spare components, essentially consumables in the mining industry. Our mission is to innovately handle the mining industry’s wear and tear and breakdown difficulties. The cost of high-end polymers and elastomers, such as polyurethane, has risen. In addition, we excel in powder metallurgy, which includes ceramics and tension carpets, allowing us to provide effective solutions to our mining clients.

Could you elaborate on how Jaws Tech dewatering panels help improve operational efficiency and durability in mineral processing plants?

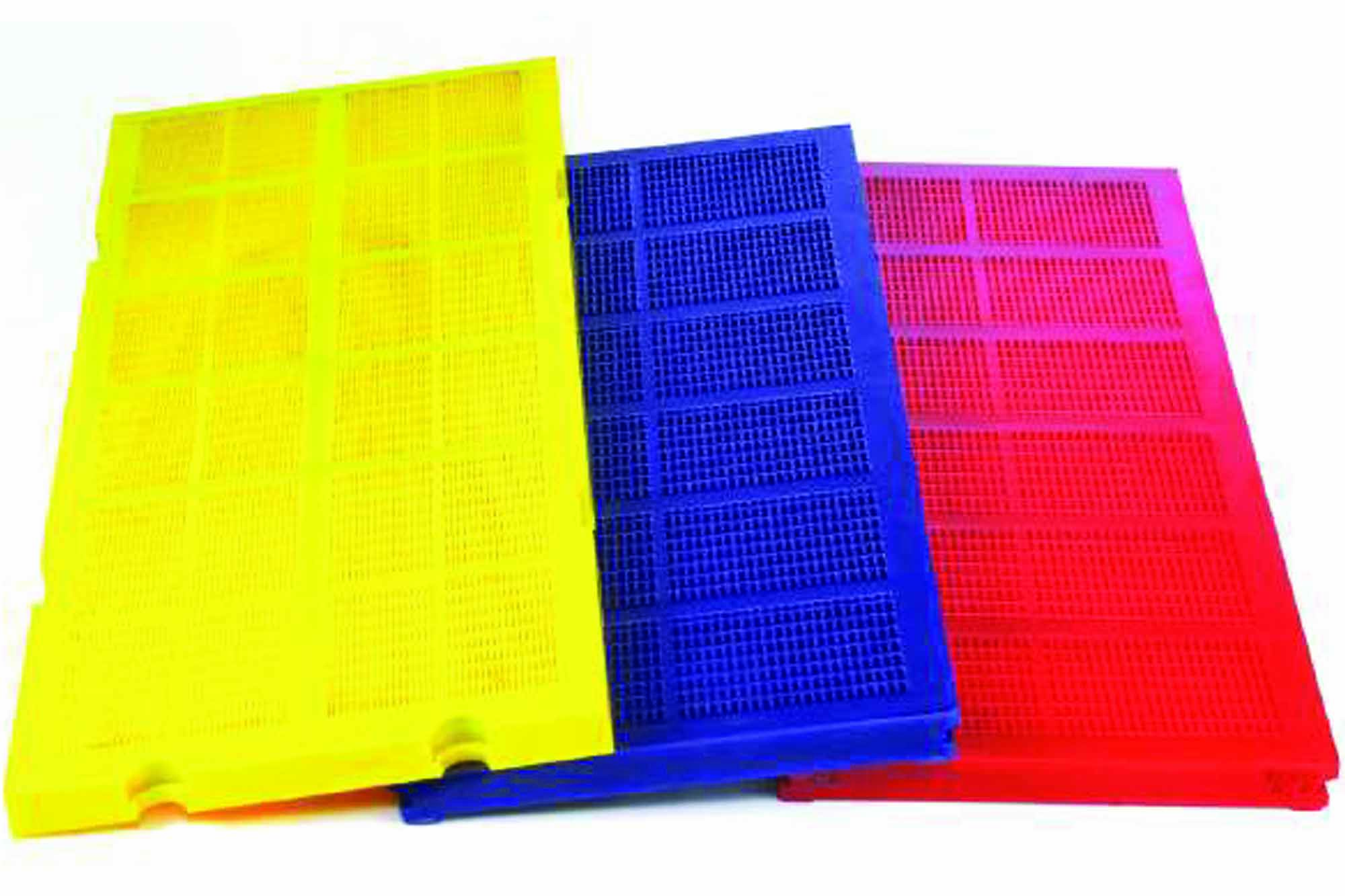

Dewatering panels play an important role in iron ore and mineral beneficiation processes. Many local manufacturers typically supply dewatering screens, but these screens frequently fail, mostly due to choke hazards. Choking might cause failures during operation. To overcome this issue, we presented our technology, which includes self-relieving and anti-choking dewatering screens. These screens reach 90 percent efficiency in dewatering while increasing production. Because they do not choke, clients may save downtime and boost production yield.

How do your anti-clogging wire-PU screens enhance material flow and efficiency in mining operations compared to traditional alternatives?

That is another solution. When aggregate moisture content is high, there is a risk of choking. To tackle this, we implemented anti-clogging technology that combines high-carbon spring steels and PU sponges. This self-relieving technique effectively prevents choking, making it ideal for handling aggregates.

Could you share insights on how Jaws Tech conveyor solutions help mining operations improve productivity and minimise downtime?

Conveyors are extremely useful in the mining industry. However, when they gather a sufficient quantity of carryback, they can cause cleanliness concerns in the plant and require operators to expend significant effort in dust collection, resulting in hazardous conditions.

To address this issue, we produced our Kitto conveyor cleaning solutions, which include main scrapers, secondary scrapers, and bristle-type scrapers. This approach can cut carryback by 95 percent.

Customers profit in two ways: first, they can sell the carryback material alongside the commodities gathered on the conveyor, and second, the factory will remain cleaner and more sanitary. Furthermore,

this technique increases the conveyor’s life, reducing the chance of malfunctions. This is how we help mine operators with our scraper and conveyor cleaning technology.

VSI crusher rotary tips are known for their wear resistance. How does Jaws Tech ensure that its rotary tips offer longer life and better performance compared to other alternatives in the market?

There are numerous VSI rotary tips for crushing large materials into aggregate form. However, their performance hours are often fairly short when employing ordinary tungsten carbide tips in vertical shaft impactors.

To overcome this issue, we developed a low-level micron powder metallurgy process that dramatically extends the life of these carbide tips. By integrating this powder metallurgy with various metal alloys, we can create high-performance VSI tips. As a result, these tips can provide nearly double or triple the lifespan of those now available in the local market. This is a unique solution in the industry.

How is Jaws Tech promoting eco-friendly practices in its product design and manufacturing processes?

We focus our eco-friendly efforts on recycling specific elements to lower carbon footprints. We can make valuable aligner pads and other recyclable materials by crushing waste plastics on the market. This is how we help the system remain sustainable, another component of our continuous evaluation.

In what ways do you think events like IMME contribute to networking and fostering partnerships within the industry?

We are a manufacturer based in the south of India. As many know, most mining activities occur in the northeastern region, making it difficult to connect with such prospects even today. While there are many individuals online, face-to-face encounters might be challenging. In this context, events like the IMME provide a fantastic networking opportunity. This platform offers manufacturers a valuable opportunity to display their capabilities in both the B2B and B2C segments.

This year’s IMME was extraordinarily well organised and managed, and we are delighted to participate. Indeed, the IMME organisers took a different approach this year. They allowed us to schedule meetings with any OEMs or clients we wanted to meet, and customers could also request appointments with us.

For more information, visit: https://jawstechengineering.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)