Digital Twins Transforming Construction Ecosystem

By Edit Team | September 16, 2023 5:20 pm SHARE

Digital twins bridge the gap between construction and innovation, revolutionising planning, execution, and maintenance.

Digital twins redefine construction, blending virtual and physical realms for efficient project planning, execution, and maintenance, says Harsh Pareek, the Regional Sales Director for India and SAARC, at Trimble Solutions.

How are digital twins revolutionising the construction industry’s approach to project planning, execution, and maintenance?

In the rapidly evolving landscape of the construction industry, the emergence of digital twin technology has introduced a groundbreaking paradigm shift in managing building operations and maintenance. As the industry embraces innovative solutions, digital twins have emerged as a transformative tool, offering a virtual replica of physical structures and systems. This advancement is not only redefining the way we approach construction but also revolutionising the post-construction phase by streamlining building operations and maintenance processes like never before.

Digital twins make it possible to precisely visualise and stimulate the entire process during project design, which makes it possible for stakeholders to predict problems, streamline processes, and come to conclusions before any actual construction takes place. This proactive strategy, in turn, reduces expensive delays and design flaws.

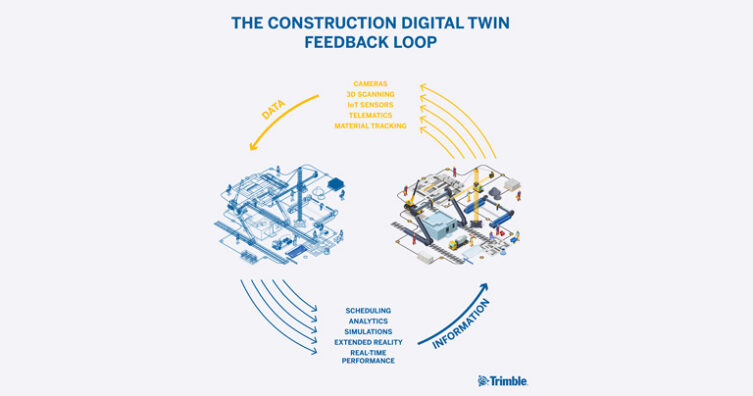

Additionally, digital twins also improve team collaboration and communication during project execution and reflect real-time changes from sensors and IoT devices connected to the actual construction site. This makes sure that all involved parties have access to reliable, current information, allowing them to keep track of developments, spot inconsistencies, and uphold quality standards throughout the construction process.

Once a project is completed, the digital twin continues to serve as a valuable tool for ongoing facility management. The technologies effortlessly combine data from numerous sources to produce comprehensive virtual models that accurately represent the intricacies of the actual world. The digital twin technology enables the construction sector to streamline operations, cut costs, and improve overall project outcomes by bridging the gap between the physical and digital realities.

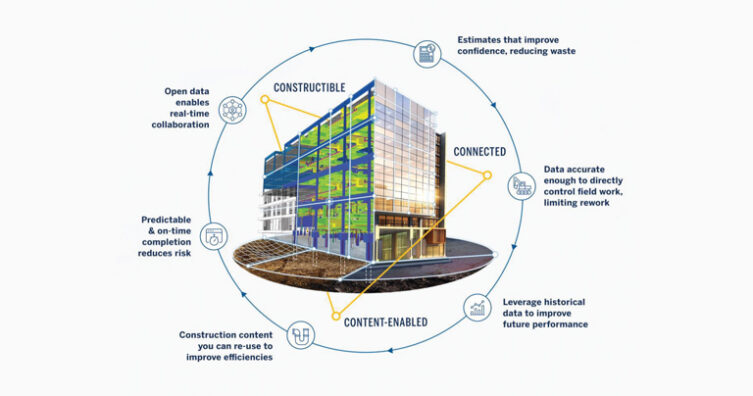

By providing unmatched insights, efficiency, and accuracy, digital twins are fundamentally altering the construction industry’s approach to project planning, execution, and maintenance. Trimble, a leader in construction technology, is at the forefront of leveraging this innovation.

What key technologies and data sources are integrated within digital twins to enhance collaboration and decision-making across construction projects?

Digital twins in construction seamlessly integrate a diverse array of key technologies and data sources to elevate collaboration and decision-making throughout construction projects. At the heart of this synergy lies Building Information Modeling (BIM), which furnishes intricate 3D models amalgamating architectural, structural, and system data, fostering efficient design collaboration and conflict detection.

This data forms the foundation of the digital twin and ensures accurate representation. Its robust sensor technologies collect real-time data from construction sites, encompassing statuses like environmental conditions, equipment status, and worker locations. Another key technology is the Internet of Things. The IoT devices are also integrated into digital twin technology, enabling the monitoring of equipment performance and health. This data-driven strategy helps with preventive maintenance, cuts downtime, and boosts operational effectiveness.

This data forms the foundation of the digital twin and ensures accurate representation. Its robust sensor technologies collect real-time data from construction sites, encompassing statuses like environmental conditions, equipment status, and worker locations. Another key technology is the Internet of Things. The IoT devices are also integrated into digital twin technology, enabling the monitoring of equipment performance and health. This data-driven strategy helps with preventive maintenance, cuts downtime, and boosts operational effectiveness.

Additionally, Trimble uses geospatial data to ensure accurate positioning and location information by integrating GNSS (Global Navigation Satellite Systems). As a result, the digital twin is more accurate, and on-site activities can be better coordinated.

Through these cloud-based technologies, which enable project stakeholders to access the digital twin from any location and enable real-time discussion and decision-making, collaboration is promoted. These technologies collectively furnish an enriched ecosystem that empowers stakeholders to make informed decisions and achieve more streamlined, efficient, and successful construction.

Could you provide examples of successful projects or case studies where the implementation of digital twins led to improved construction project outcomes in terms of cost, time, and quality?

Could you provide examples of successful projects or case studies where the implementation of digital twins led to improved construction project outcomes in terms of cost, time, and quality?

Implementation of digital technologies such as BIM and cutting-edge technology has seen a significant shift in the construction sector. Not only have the industry players adopted digital technologies, but they have also delivered big-ticket projects in India and around the world with considerable savings in materials and manpower usage.

Several technologies that seemed too futuristic a decade ago, like drones, robotics, AI, and augmented or mixed reality (AR/MR), are now actively being adopted and used on construction sites today. Thanks to technological advancements, these digital models have taken the form of digital twins. KONE recently used digital twins to analyse how people are using elevators. Sensors were used to track how people moved through buildings. The goal is to cut down on elevator wait times, especially during busy mornings.

Tekla structures have been extensively working in India and the Middle East to deliver big-ticket projects that are easily constructed and delivered. One such project is the Museum of the Future in Dubai.

Eversendai, the company behind iconic structures like the Burj Khalifa and Petronas Tower 2 in Malaysia, was one of the contractors involved in the construction of the Museum of the Future in Dubai. They found the calligraphy and complex structure a time-consuming process and used Trimble’s tech solutions to streamline and simplify the entire project’s modeling and execution.

This automated change management was one of the most beneficial features of using advanced modeling software like Tekla Structures. It enabled real-time teamwork, which not only eliminated the clashes at an early stage but also contributed to completing the project with more efficiency and better quality.

In what ways can the concept of digital twins be extended beyond individual construction projects to create a more interconnected and data-driven construction ecosystem?

The concept of digital twins can transcend individual construction projects to forge a more interconnected and data-driven construction ecosystem through various avenues. One approach involves the integration of digital twins across multiple projects within a region, enabling stakeholders to gain insights from a broader perspective. By interconnecting these digital twins, a seamless flow of information can occur, fostering collaboration, knowledge sharing, and standardised practices. Moreover, extending the concept to city-scale applications, such as smart urban planning, offers the potential for optimising resource utilisation, traffic management, and environmental sustainability. This ecosystem can also incorporate supply chain partners, enabling real-time tracking of materials, reducing delays, and enhancing efficiency.

We see a bigger possibility than just individual construction projects when we think about digital twin applications. A linked, data-driven construction environment can be built using the larger framework, which has the potential to improve project members ability to communicate and understand one another. By establishing benchmarks and spotting market trends, this networked ecosystem can promote innovation and raise industry standards for the construction industry.

Ultimately, this extended digital twin ecosystem has the capacity to usher in a new era of construction excellence characterised by enhanced coordination, sustainability, and innovation.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)