Doka to showcase innovative scaffolding and formwork products at bauma 2025

By Staff Report | March 18, 2025 11:56 am SHARE

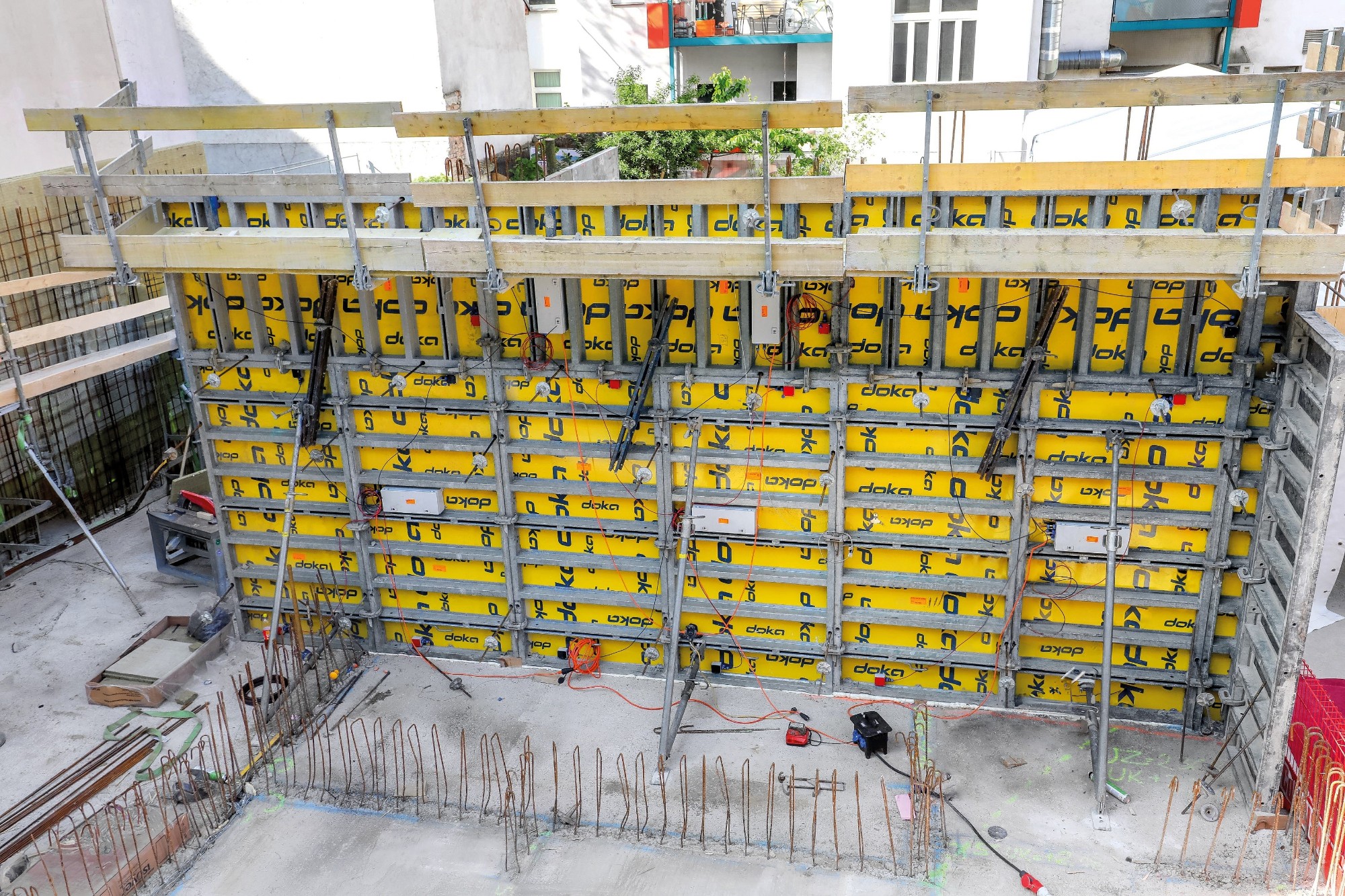

At bauma 2025, Doka and Umdasch Group will showcase 40+ innovations in formwork, scaffolding, and automation, driving efficiency, digitalisation, and sustainability to future-proof construction and enhance productivity. Visit booth FN.420 – FN.423.

At bauma 2025, Doka and parent company Umdasch Group will showcase over 40 groundbreaking innovations in formwork, scaffolding, and other key areas spanning a building object’s entire lifecycle. Visitors (booth FN.420 – FN.423) will experience new technologies, products, and materials designed to drive efficiency and productivity on the job site. The aim is to make concrete construction fit for the future.

For decades, construction productivity has been lower than that of other industries. Between 2000 and 2022, manufacturing productivity increased by 90 percent and the overall economy by 50 percent, but construction improved by only 10 percent, or 0.4 percent per year (McKinsey, 2024).

“We cannot build the future with yesterday’s methods,” says Robert Hauser, CEO of Doka. “The construction industry is facing enormous challenges – above all, it must overcome its productivity stagnation. While we are just one part of the bigger picture, we are committed to creating real value within our field. Through new technologies and, most importantly, the consistent digitalisation of the entire formwork process. Making this possible for our customers must be our ambition – nothing less.”

Doka’s expanding portfolio of products and services is helping to future-proof the industry by updating outdated construction methods. At bauma 2025, Doka will showcase over 40 innovative products and solutions, all of which are designed to help customers increase productivity. To highlight its ambitions for the next era of construction, Doka will unveil its vision of a fully digitised formwork process. The goal is to enable seamless process integration via a connected platform, resulting in unparalleled transparency and full control over the entire formwork and pouring workflow, anytime and anywhere.

Smart construction area: Automation, robotics & more

At bauma 2025, Doka will demonstrate cutting-edge automation in formwork solutions. The new Doka LeanForm streamlines concrete wall construction with a pre-assembly platform, lowering transportation costs and wait times. A robotic system helps to mobilise and position components. The DokaXBot Lift, redesigned for greater safety and efficiency, precisely positions formwork up to 5.7m high. Doka FormDrive automates high-rise and infrastructure projects using a mobile control unit that lifts and steers formwork, reducing manual labour and increasing safety and productivity.

Multiple premieres in wall and slab formwork

To promote using new, more environmentally friendly concrete mixes, Doka has created an intelligent heated formwork prototype. The prototype uses targeted heating to accelerate delayed strength development in CO₂-reduced concrete, allowing for safe and efficient use on-site. Integrated digital sensors enable real-time concrete monitoring, which improves on-site performance. Following successful trials in research projects and on real-world construction sites, the prototype will make its international debut at the fair. Doka’s technology demonstrates that formwork is more than just a supporting structure; it is a critical enabler in the transition to low-carbon concrete and the decarbonisation of construction sites. “As one of the largest GHG emitters worldwide, the construction industry must evolve,” says Hauser. “CO₂-reduced concrete is a key driver of change, and we are committed to supporting a lower carbon construction future, in line with our ambitious goal of achieving net zero by 2040. We are excited to present our prototype at such an important show.”

Visitors can look forward to even more highlights:

- By incorporating circular economy principles, Doka demonstrates that sustainability and economic efficiency are inextricably linked. The Xlife top sheet is the first Doka formwork sheet with a core made entirely of upcycled plastic. It is specifically designed for high durability and multiple reuse cycles, lowering material consumption and maintenance costs while providing both financial and environmental benefits. When the sheet reaches the end of its lifecycle, it is returned to a closed-loop system and recycled into new sheet cores.

- In terms of slab formwork, the DokaXdek system family, which includes the DokaXdek table, DokaXdek panel, and DokaXdek I-frame, will be showcased at the show with the latest innovations.

- A new safety upgrade for beam slab formwork, featuring the Safeflex sliding mesh and Safeflex system, raises the bar for stability and safety in precast and in-situ concrete applications.

- To increase efficiency, Doka is adding new components to its product portfolio: One standout feature is the innovative XT20 beam, which has a 50 percent higher load capacity and saves up to 15 percent on materials and costs. Despite its new features, the extra tough XT20 maintains the familiar H20 dimensions without sacrificing compatibility. Furthermore, the new Doka Eurex 20 basic floor prop combines increased load-bearing capacity with reduced weight, resulting in easier handling and lower costs for all slab systems.

- Another significant addition to Doka’s formwork portfolio is making its debut. Doka acquired Malaysia’s MFE, the market leader in monolithic aluminium formwork, in 2024. Doka is now introducing monolithic formwork technology to the bauma 2025 exhibition for the first time, demonstrating its impact on modern, high-speed construction.

Raising the bar in scaffolding

Doka, in collaboration with AT-PAC, the group’s dedicated scaffolding brand, will demonstrate new scaffolding solutions designed to improve efficiency and safety for both construction and industrial customers. A dedicated area for the new scaffolding product lines will showcase advancements in façade scaffolding, access systems, and expanded shoring applications, increasing Ringlock scaffolding’s versatility for construction projects. These new product lines will be displayed alongside an impressive 30-meter scaffolding tower with an integrated viewing platform, a unique booth feature that provides visitors with a breathtaking panoramic view of the bauma fairgrounds.

Lighter and more versatile shoring solutions

Doka will unveil next-generation shoring systems at bauma 2025. DokaXshore, which makes its global debut, is a lightweight, tool-free system with a leg load capacity of 100kN, ensuring fast assembly and high safety. The well-known Doka UniKit heavy shoring system, which is used in high-rise and infrastructure projects, will receive two major upgrades: a 400kN wall-mounted support for tight spaces and Ringlock scaffolding integration for secure access at any height.

Under one roof

Visitors can go on an immersive journey through a dynamic indoor exhibition that is shared with the parent company Umdasch Group. There is an exciting outdoor area dedicated to smart construction, as well as the striking Ringlock scaffolding tower. More than 100 live demonstrations will bring the ‘we make it work’ theme to life during the event, which takes place in Munich from April 7 to 13. The Umdasch Group has a stronger presence than ever before. The group brings together leading brands and expertise, bringing key themes like renovation, sustainability, and digitalisation under one roof. Visitors will see firsthand how this holistic approach is shaping the future of construction by providing integrated solutions throughout the lifecycle of a building object.

For more information, visit: https://www.doka.com/in/index

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)