EclipseEdge eases installation of raised roof edges while reduces materials costs

By Edit Team | August 24, 2017 8:23 am SHARE

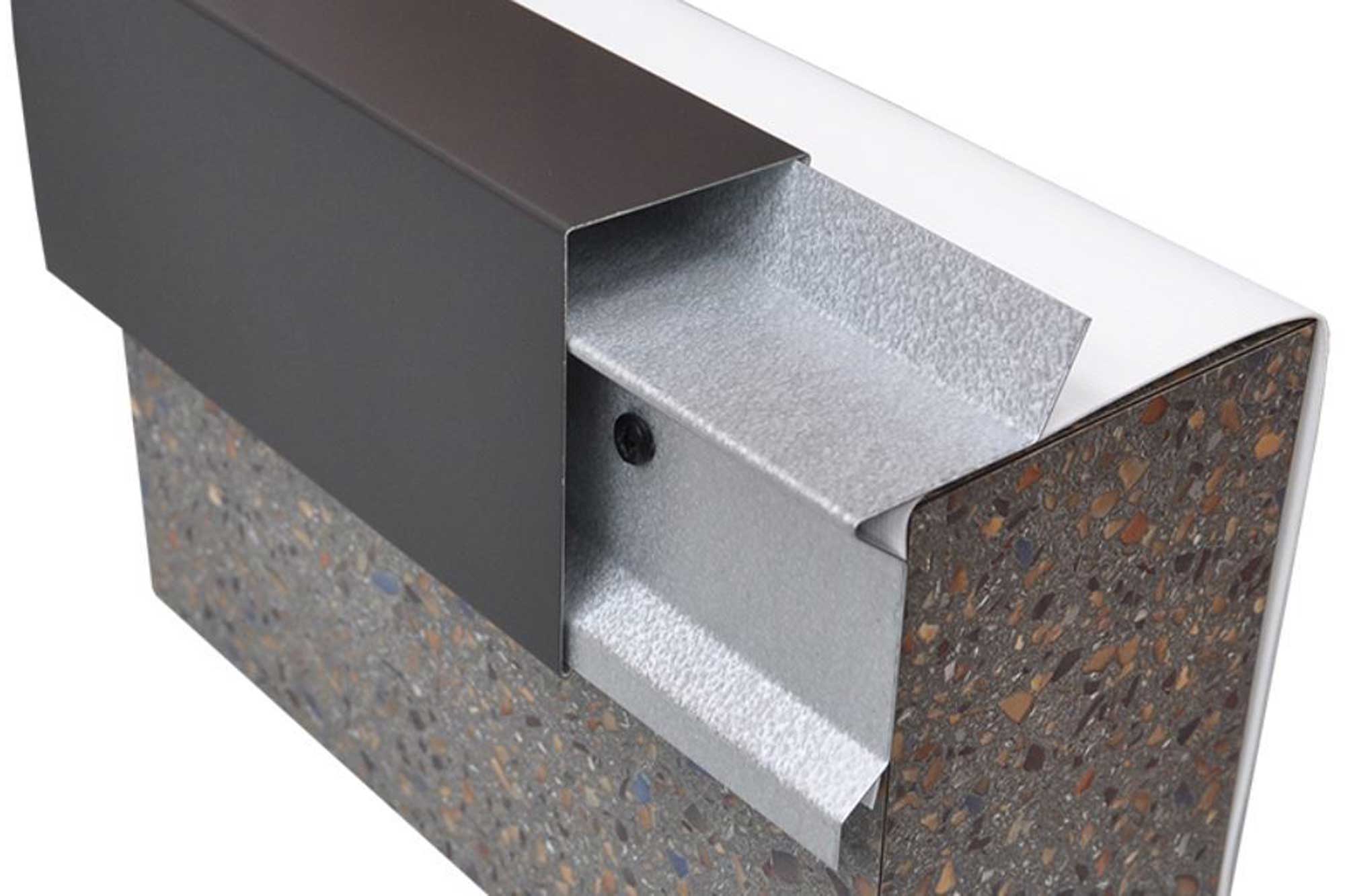

New EclipsEdge edge metal profile from Mule-Hide Products Co. makes installing raised roof edges, gravel stops and full coping caps in single-ply roofing systems faster and easier while also reducing materials costs.

A two-part design, with a base and a top cover, makes EclipsEdge extremely versatile and helps eliminate entire steps often required in traditional installations. The profile can be used in TPO, EPDM and PVC roofing systems and is not sensitive to membrane thickness.

EclipsEdge is not fastened to the horizontal surface of the roof, so there are no fasteners to seal with membrane flashing. There is no need to install a continuous clip when the face dimension exceeds 4 inches. The ends of the top cover are notched for easy overlapping, eliminating the need for joint covers.

Using the EclipsEdge provides the same aesthetics from the ground as traditional coping cap installations while using a fraction of the metal. It also eliminates the need to measure and fabricate copings, and then return to the jobsite to complete the job.

Fastener holes are pre-punched for quick installation. EclipsEdge can be installed using battery-operated equipment.

EclipsEdge complies with ANSI/SPRI ES-1, “Wind Design Standard for Edge Systems Used with Low Slope Roofing Systems.”

EclipsEdge is available in prefinished steel, aluminium, stainless steel and bonderized steel. The standard base is fabricated from 22-gauge galvalume Plus steel or .050-gauge aluminium. The cover is available in 24-gauge galvalume with mill or Kynar finish, 24-gauge stainless steel or .040-gauge aluminium in mil or Kynar finish. All covers measuring 9 to 13 inches are fabricated with aluminium.

Features and benefits

• Easy fast install

• Cuts material and labour costs compared to conventional applications

• Eliminates the need for continuous clip when face dimension exceeds 4”

• Not sensitive to membrane thickness

• Eliminates need for fasteners and required flashing membrane on horizontal surfaces

• Can be installed with cordless drill

• Fastener holes are pre-punched to ease installation

• Pre-notched for easier overlapping during installation

• Overlap design eliminates joint covers

• Metalwork is automatically included in a Mule-Hide labour and material warranty

• Eliminates the need to measure and fabricate copings (Requires a return trip to complete the job)

• ES-1 compliant

• Lower installed cost solution for raised roof edge/gravel stop and coping caps.

For more details, visit www.mulehide.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)