Energy saving coatings to reduce global warming

By Edit Team | November 12, 2021 6:24 pm SHARE

This article talks about Heat Reflection Technology, a simple yet cost effective method to reduce global warming.

Abstract

Every year thousands of people die due to intense heat in summer, a huge amount of energy is consumed in bringing tolerable controlled temperature within homes by using air-conditioners (AC), coolers and other local methods. It has been found that a temperature of ~40o C will bring the roof top temperatures to about 65o C at the peak day hours, between 12 pm to 2.00 pm. The consumption of electricity under these conditions is very high. A 10o C decrease in the temperature of the room can bring down electricity cost by at least 50 percent. A rough calculation has shown that for a city having 10 lakh roof top houses of approximately 1000 sq. ft., with a 1.5 ton AC, running only for 10 hours a day, can bring down electricity savings equivalent to a cost reduction of about `480 crores if the room temperature be reduced by 10o C.

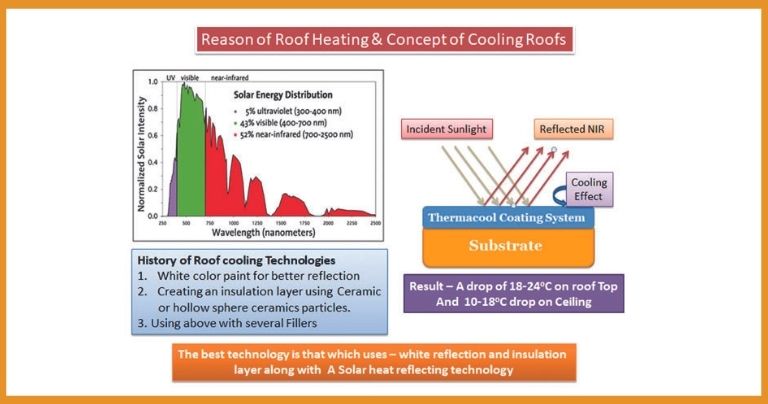

This can be achieved by using solar heat reflecting cool roof coatings (SHRC). A cool roof coating can be created on the roof top of a house which can bring down the ceiling temperature by as low as 20o C. The concept of cool roof coating here is to make use of certain special pigments which reflect more than 89 percent of near infrared radiations from sun, which constitute 52 percent of the total sun radiations. Successful coatings were made which on application on roof top can help bring the temperature of roof top by 18-20o , and the temperature in the room by 6C-9o C. Similarly cool roof coatings for steel surfaces are developed which reduce the temperature by 9.5o C.

Introduction

Last two decades have seen severe climate changes with number of tsunamis, hurricanes, wild fire, cloud bursting, volcanic eruption, glacier melting and severe cold and hot conditions on specific lands. What could be the one reason for these severe changes in climate? The one possible answer is Global Warming, which has risen by just one degree in the last few decades. Now imagine, what worst could happen when the global temperature, as predicted would cross 2o C in the coming one or two decades. Recollecting the reasons behind this rise in global warming is the burning of fossil fuels in power generation and vehicular pollution. That is why the effort is to control this temperature by reducing the use of coal and oil in power plants, using electric vehicles to reduce pollution. World-wide, the action has started and India is not far behind in this effort. India’s goal of power generation using alternative energy methods, especially wind and solar is increasing at a very fast pace and we are much ahead in achieving our targets.

In this short article I want to add a very simple and cost-effective method to control Global warming and if this concept is accepted collectively and implemented with a proper government policy, can create a great dent in reducing global warming. This method is the use of a simple architecture coating on roof tops of houses, industrial establishments, water thanks, automotive transport vehicles and tractor tailors. This architectural coating is modified to absorb heat IR radiations (52 percent of total solar radiations), followed by their immediate reflection. This technology is therefore called as Solar Heat Reflecting Technology to precede cool roof coatings, applied on roof top of buildings, and industrial establishments whether of concrete, steel or any other artificial roofing material. If implemented properly, it has an annual market of `2500 crore and can reduce substantial carbon footprints in terms of thousands of ton per annum.

Concept of Solar Heat Reflective Coatings

Fig. 1 gives a schematic of solar radiation which mainly consists of UV, visible and infrared radiation. It is IR radiation, especially near IR (from 750-1250 nm) which brings maximum heat to roof. Hence any technology for cool roof must eliminate this portion of IR radiation. This therefore can be achieved by modifying the formulation of conventional architectural coatings by introducing IR absorbing pigments. A right composition of these pigments with suitable size can absorb most of this radiation, followed by its immediate reflection. Other two factors which help in the cooling are white colour and presence of insulation additives. The Thermogreen Solar Heat Reflective coating has all such gradients and that is why it is an effective coating to reduce heat. It is a patented technology, developed at IIT Bombay and has been well tested using several proofs of concepts in industrial sheds, railway transportation and housing.

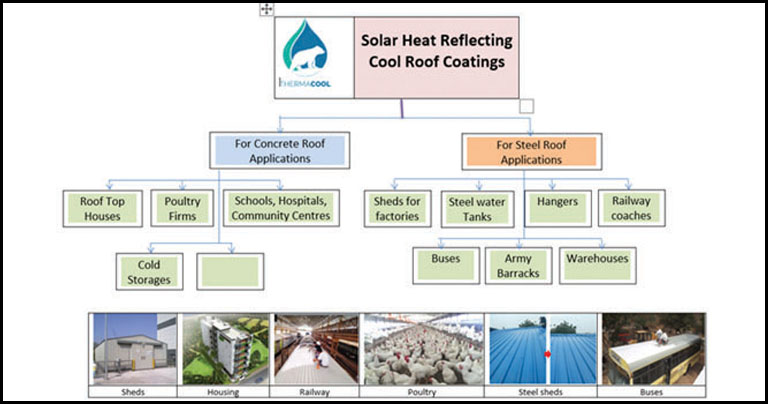

Fig – 2 – Application of SHRC coatings in various sectors

Fig. 2 displays various possible applications of the SHRC coatings which goes from simple concrete housings, schools, factories, hospitals buildings, industrial sheds and warehouses, railway and bus transportation, roof top water tanks and many more. The apporimate market of SHRC has been found to be `2500 CR per annum.

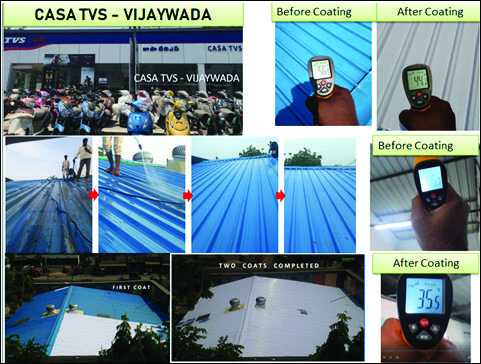

Let us see now some of the results of proof of concepts on many industrial and utility buildings. The first example is the huge drop in temperature of a TVS industrial shed made of coil coated steel in Vijaywada.

Fig. 3 – An example to show the cooling effect on a steel shed roof by 12 Degree – C.

Fig. 3 showed a drop of 12o C after application of this coating on the steel roof top and 11o C drop in the temperature of ceiling which is a substantial drop in temperature for the comfort of workers, working under the shed.

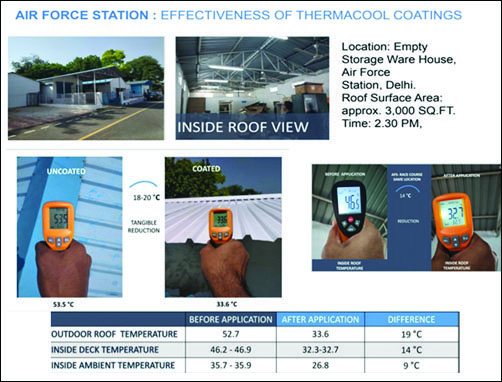

A drop in temperature of 18-20Degree C of the roof temperature at an ambient temperature of 34 Degree C with 9 Degree C drop in the temperature of the room.

Fig. 4 is the most pertinent example to illustrate the use of such coatings. A drop of 18-20o C was noticed on the steel roof top at an ambient temperature of 34o C outside.

This resulted into the temperature in the room as 26o C, almost 9o C drop in temperature from outside. The next example is that of railways and bus transportation where a substantial cost reduction of electricity consumption can be achieved by coating roof tops by SHRC coating (Fig. 5) and longer life and fuel savings can be achieved for AC buses.

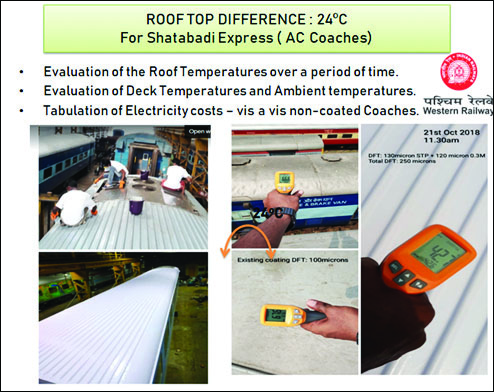

The application of SHC Coating on the roof of a air-conditioned compartment was 24oC by its application which can substantially bring down the electricity consumption of the AC.

The coatings supplied by Thermogreen Cool Coat Pvt. Limited are simple and are in two categories, one for concrete roofs which are acrylic based and are Griha certified eco-friendly category with a durability of 5 years. The coatings those applied on steel roofs are Polyurethane base and are solvent base with a durability of 8 years. A list of various products available along with suitable primer and a modified fire retardant coating are given in the following table.

Energy Saving and Reduction in Global Warming

Finally it can be shown how much electricity savings can be made on running your AC’s at home which would give you monthly savings in the electricity bill cost and annual savings in carbon footprint. The results are summarised taking the example of a roof top house of 1000 Sq.Ft with an AC of 1.5 tons running for 10 hours a day. Application of our coating will save 7 units of electricity per day equivalent to about `314 savings per month and a savings of C foot print of 9 m tons per annum taking approximately 6 m AC’s in a city.

(This article is authored by – A.S.Khanna, IIT Bombay, Powai, Mumbai – 400076. Email id-anandkh52@gmail.com)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.