Friends Equipment owns India’s largest diameter TBM

By Edit Team | February 10, 2023 1:48 pm SHARE

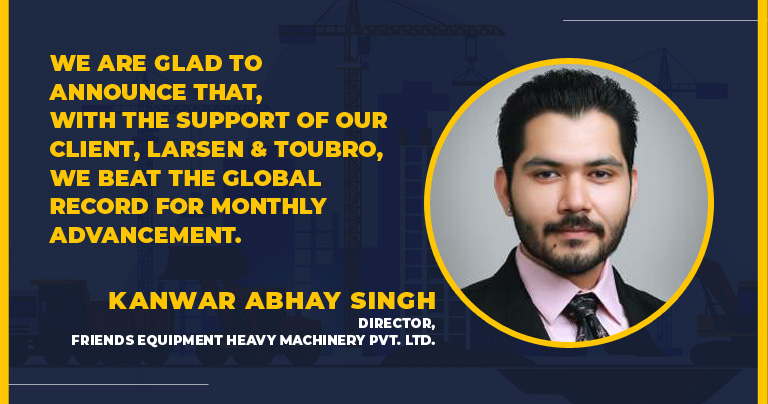

Kanwar Abhay Singh, Director of Friends Equipment quickly explained the ground-breaking and famous coastal projects with their TBM in an exclusive interview with B2B Purchase.

Bauma CONEXPO 2023 was a positive experience for us as we received favourable inquiries. We also located several local vendors for our TBM spare parts needs, where we discussed ideas on how to best localise.

TBM is one of our most important businesses in India, and we are grateful to our customers for that. Our commercial performance has been pleasing in recent years, as we are engaged in the most of projects in India. We’d wish to use this opportunity to promote our other products, such as Jumbo drills, shotcrete, cotton pickers, and so on.

Which innovations are happening in TBM? How are these innovations adding value to your projects?

We have over ten machines now working in India. They work in India’s east, west, north, and south, including the giant diameter TBM in the country, with a 12.2-meter diameter for the Mumbai Coastal Road.

In Bangalore, we have encountered the toughest geology in India. And no TBM came out of the last project in Bangalore without significant damage. Our first two TBMs, on the other hand, completed the task successfully and made the final breakthrough without any substantial setbacks or damage. Another watershed moment will occur in February. Our TBM will become the first to complete its final breakthrough in Bangalore.

Can you talk about your coastal projects where these TBMs will be primarily used?

The tunnel boring machine, named “MAVALA,” was supplied in mid-2020, and there was a peak CO2 situation worldwide. The foreign expatriates were not able to visit India for the installation and commissioning of this TBM. During the pandemic situation, we formed our Indian team, and with the virtual support of CRCHI, we were able to launch this TBM successfully and have almost completed the tunnels in about two years. We are pleased to announce that, with the assistance of our client, Larsen & Toubro, we broke the world record for monthly progress.

You have been involved in multiple projects. Which challenges do different geographies face in terms of safety, management, and tunnelling?

Tunnelling is a tricky business because each project has different geologies, and each TBM must be designed according to the geology. Some places are safe, some are hard to very hard, some are mixed, and some are underwater. In the case of metro and road projects, the TBM must pass through dense populations and beneath old structures. We have to ensure that there will be no damage to people or property. The engineers are on the job 24 hours a day, seven days a week, to ensure the excavation runs smoothly.

How do you ensure quality and efficiency across your TBM range?

The TBMs we supplied had better parameters and were built with branded, tried-and-true parts. Our TBM has already proven its quality and efficiency. We set a world record in the Coastal Road Project and were nearly finished tunnelling in Bangalore, India’s toughest geology, while other TBMs are still struggling to break through.

For more details visit: https://friendsequipment.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)