All over the world, for decades, shipyards have been using the variable speed, all position carriages for mechanisation of welding and cutting for improving productivity and quality at their yards. Gullco International is a prominent name in welding sector for the ship building vertical. The company offers the latest and advanced low cost automation in welding, cutting and plate bevelling in ship building sector.

“There is tremendous shortage of skill welders, leading to delays in projects and deterioration in the quality of welding,” says Sateesh Desai, National Head – Sales & Service, Gullco International. The company is one of the renowned manufacturers of automated welding carriages, welding tractors, cutting carriages, welding automation and accessories which supports to the shipbuilding industries. These equipment are selected for several areas of production on the ships.

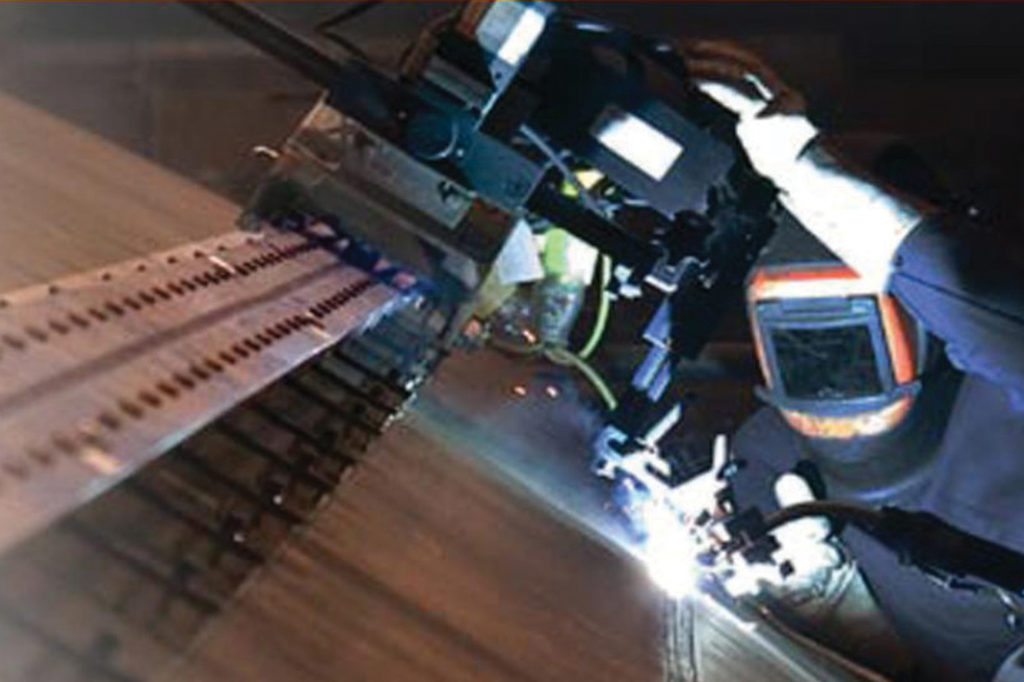

Explaining the most advanced technology in shipbuilding sector, Desai says, “The use of low cost welding and cutting systems plays a vital role for increasing ‘arc time’, reducing man hours, and at the same time improving quality in welding and cutting operations. Arc on time is one of the management tools for measuring the shipyard’s output in terms of efficiency. With the deployment of these equipments, there is also reduction in reworking time, saving in consumables, reduction in skilled labour and lesser crane handling operations.” He says that the skill of the welder is transferred to the equipment. It is believed that the equipment reduces operator fatigue, and, at the same time the equipment can be used continuously at high arc times.

When it comes to applications including positional welding and cutting, the highly versatile KAT travel carriage system is selected. Explaining the company’s offerings in this system, Desai adds, “Gullco KAT allows quality welds and cuts to be made in any position, including horizontal, vertical and overhead. This greatly enhanced efficiency of welding and cutting for the ship building process. Gullco Oscillators provide high quality mechanised welds in all positions, including overhead.”

KAT Oscillating System has been found to be extremely reliable in the variety of positions and environments within the shipyard. It is claimed that this greatly reduces production times while improving the quality of the welds.

Speaking further, Desai says, “Fillet Welding Carriages, Moggy, manufactured by Gullco are very simple to operate. These carriages are microprocessor based with tacho feedback controls and are guided by adjustable idler guide rollers, which track vertical member of the fillet, or lap, to be welded. One or two torches can simultaneously be used for welding.” The controls are designed for continuous and stitch welding applications. Typical applications of these carriages include welding of stiffeners and bulbs to panels, fillet and lap welds on the deck.

The company claims that the plate bevelling machine featuring its popular KBM 18 and KBM 28 portable plate edge bevellers offer the quality and reliability. The bevelling process is noiseless and vibration free.

As per company claims, it’s new improved automatic gouging system provides versatility, flexibility and safety features built with an enhanced gouging function. “Combined with the KAT Automated Carriage further improvements to productivity, consistency and quality are achieved. Covering a broad range of applications, this automated gouging system can be utilised on almost all metals, including stainless steel, carbon, manganese, and chrome-moly steels. It is perfect for work with pressure vessels, wind towers and shipbuilding,” adds Desai.

Ceramic backing strips designed by the company are used in shipbuilding and other industries for producing excellent welds and radiographic results for the root run welding thereby, avoiding back chipping or grinding. These ceramic backings are available in several segmented shapes and sizes, to suit almost any application requirements.

Contact:

Gullco International India Pvt Ltd

Ground Floor, Mayfair Annex,Behind Mayfair Tower,

Final Plot No 55, Survey No 26, 27 and 28 (Part)

Bhamburda, Shivajinagar,Pune – 411005

Tele: +91-20-65260382

Mobile: +91-7709495342

Email: sateeshvdesai@gullco.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.