Amidst the dynamic landscape of modern industry, Messer Cutting Systems emerges as a trailblazer in oxy-fuel technology. Explore the transformative advantages and why discerning businesses opt for Messer’s unparalleled cutting solutions.

In today’s rapidly evolving industrial landscape, businesses seek cutting-edge solutions to enhance productivity, efficiency, and precision. One such innovation that has stood the test of time and continues to revolutionise the metal-cutting industry is oxy-fuel technology. Messer Cutting Systems, a global leader in cutting-edge manufacturing solutions, offers a comprehensive range of oxy-fuel products designed to empower businesses with exceptional cutting capabilities. Let’s explore the remarkable benefits of oxy-fuel technology and why Messer Cutting Systems should be your preferred choice.

Unleashing the potential of Oxy-Fuel Technology

Oxy Acetylene / Oxy LPG: The foundation of efficient cutting: At the core of Messer Cutting Systems’ oxy-fuel technology lies the use of oxy-acetylene / oxy LPG, a powerful fuel combination known for its exceptional cutting, heating & brazing capabilities. This gas combination enables precise cuts/joints across a wide range of material thicknesses, making it a versatile choice for various industrial applications. With Messer Cutting Systems’ oxy-fuel products, businesses can achieve clean, high-quality jobs with unparalleled speed and accuracy.

Gas Cutting Torch: Unleashing the precision: Messer Cutting Systems’ gas cutting torches are meticulously crafted to deliver exceptional performance, unmatched precision and safety. Designed with advanced features, such as a high-flow design and multiple preheating options, these torches ensure smooth and consistent cuts, even in the most demanding environments. With ergonomic designs and optimal weight distribution, Messer’s gas-cutting torches offer enhanced manoeuvrability and ease of use, reducing operator fatigue and increasing productivity. These torches can be easily used with oxy-acetylene and oxy-LPG combinations.

CNC Integration: Automation for superior results: In today’s digitally driven world, automation is crucial in streamlining operations and optimising productivity. Messer Cutting Systems’ oxy-fuel products seamlessly integrate with CNC (Computer Numerical Control) systems, enabling businesses to automate the cutting process with precision and efficiency. CNC integration eliminates human error and ensures consistent, repeatable cuts, maximising throughput and reducing material waste.

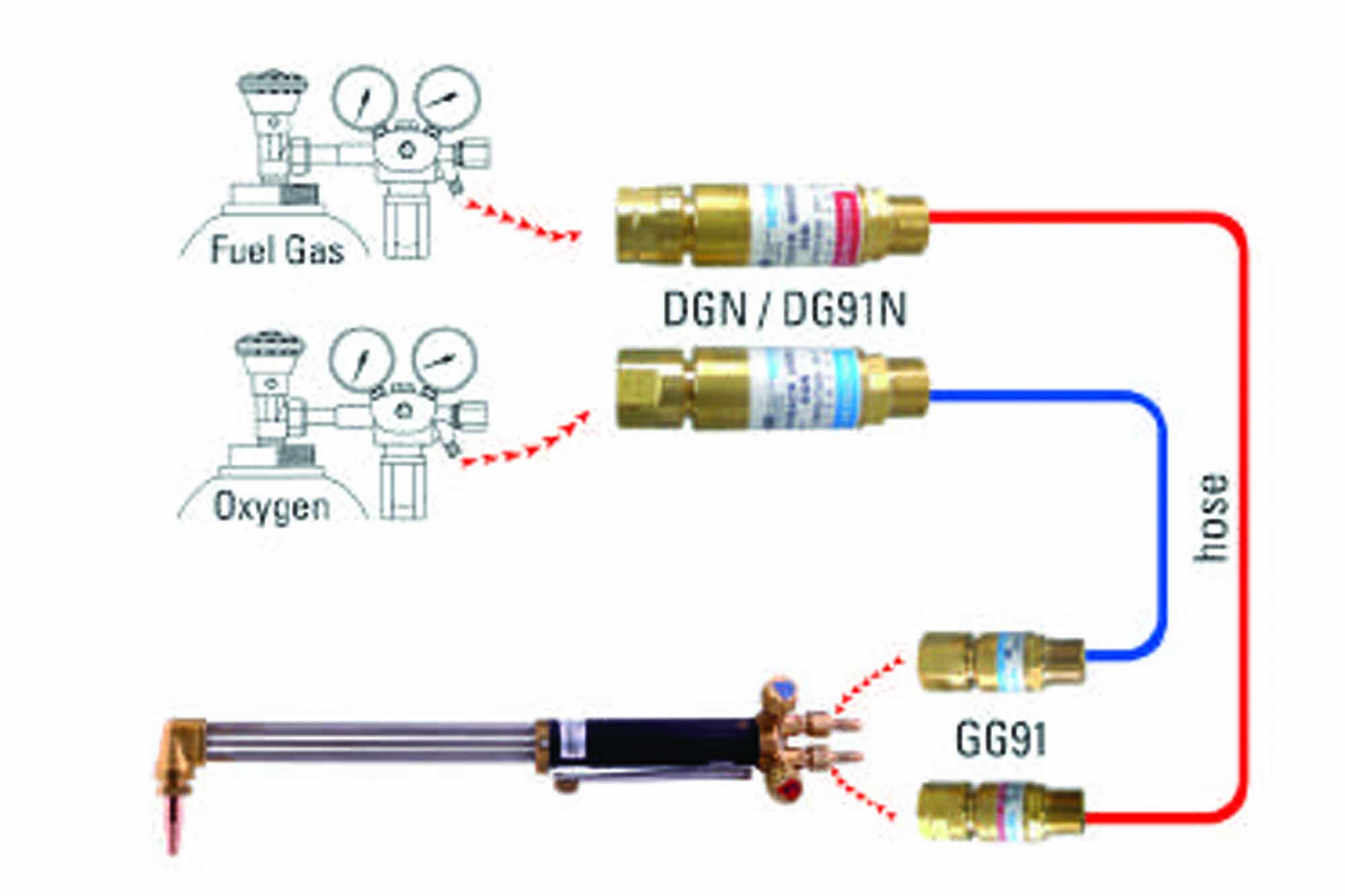

Pressure Regulator: Fine-tuning for optimal performance: To achieve optimal cutting results, precise gas flow and pressure control is vital. Messer Cutting Systems’ pressure regulators provide accurate and reliable control over the gas mixture, enabling operators to fine-tune the cutting process according to specific requirements. These regulators ensure consistent gas flow with exceptional stability and durability, resulting in uniform cuts and minimising rework.

Flashback Arrestor: Safety first: Safety is a top priority in any industrial setting, and Messer Cutting Systems recognises its significance. The Messer flashback arrestors are built with the highest quality standards, which provide robust protection against potentially dangerous flashback incidents. By preventing flame propagation into the gas supply system, these arrestors ensure the safety of operators, equipment, and the overall workplace environment.

Oxy-fuel gas brazing torches: Messer offers a wide range of oxy-fuel brazing torches suitable for oxy-acetylene and oxy-LPG combinations. The featherlight Minitherm torch, weighing approximately 100 gms, is one of the most sought-after torches by operators due to less fatigue, higher productivity and easy manoeuvrability.

Heating torches: Be it preheating, post-heating, bending, straightening or any other flame heating application in the industry, Messer has a product to offer through its dedicated Griflam series product range. Customers can choose off-the-shelf standard heating torches or customised heating solutions to suit the application demand. These torches are available for operation with several gas combinations viz oxy LPG, oxy-acetylene, fuel gas with compressed air, only LPG (working on sucked air principle) etc.

Gas savers: saving is one of the most important aspects of business operations in today’s competitive world. Messer offers gas savers for shielding gases being used in MIG/MAG applications, oxy-fuel gas economisers suitable for working with brazing stations, etc.

Messer Cutting Systems’ oxy-fuel technology empowers businesses with the precision, efficiency, and safety required to excel in the metal cutting, heating and brazing industry. From oxy acetylene to gas-cutting torches, pressure regulators to flashback arrestors, their comprehensive range of products ensures unparalleled cutting performance for various applications. By embracing Messer Cutting Systems’ oxy-fuel technology, businesses can unleash their true potential, achieve superior cutting results, and stay ahead in the competitive market.

To learn more about Messer Cutting Systems’ oxy-fuel technology and explore their extensive range of products, visit their website: https://in.messer-cutting.com/products/oxyfuel-technology/oxyfuel-technology.https://in.messer-cutting.com/products/oxyfuel-technology/oxyfuel-technology

Enhance your cutting capabilities, embrace precision, and drive your business to new heights today with Messer Cutting Systems’ oxy-fuel technology.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.