Light Steel Frames reduce waste in PEB structures

By Admin | October 31, 2022 4:07 pm SHARE

Green construction is gaining traction from all sides, and prefabrication is driving this change in a big way.

What unique features of your solution range give you a cutting edge over others?

Our systems make the prefab manufacturing and installation process simple and cost-effective. Our construction technology is based on our thorough understanding of the limitations of the Indian market, including execution capabilities. Still, it capitalises on the market’s smart, cost-efficient opportunities, which reduce overhead costs and make technology affordable. Our construction process requires low capital and delivers high ROI for our clients.

How is the increased usage of steel and PEB advised for sustainability?

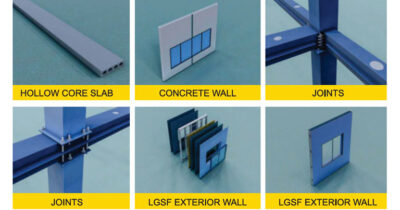

The construction method in a Light Steel Frame (LSF) uses no polluting materials and reduces energy consumption by about 70 percent. The CO2 emissions are also lower, and all materials used in construction can be recycled. In addition to steel products being completely recyclable, the accuracy and timeliness of manufacturing and construction of LSF components lead to less wasted material, ultimately reducing the environmental impact. Steel is 100 percent termite proof and doesn’t need any anti-pest treatment. At Steel ion, composite prefab elements are produced using offsite construction methodologies at low-cost decentralised yards near the construction site. This project-based offsite construction approach helps us to reduce overhead and transportation costs. This enhances agility in our services while reducing emissions, making our construction process environmentally sustainable.

How does your company contribute to green initiatives to increase sustainability in construction?

Due to its inherent advantages, prefabrication is one of the best eco-friendly alternatives for both consumers and construction companies as it is cost-efficient. They greatly minimise the amount of waste produced during the construction process. The materials used in prefab construction are green and reap financial benefits in the long run with a low maintenance cost and greater lifespan. At Steel ion, our offsite construction methodologies, which make use of sustainable materials, reduction in the wastage of construction materials, and our mobile yards in proximity to the construction site, which reduce overhead, and transportation costs and significantly reduce emissions, are some of the positive measures already being implemented at our construction sites. What offers an edge to Steel ion among the established players in the market is its approach to quickly embracing the changes that are highly sustainable, energy-efficient, and time-bound.

Do you notice any shift in the procurement pattern for your solutions?

Yes, our customers are quickly embracing change and seeking solutions that are not only qualitatively superior and long-lasting but also environmentally sustainable. While the pace of change has been slow, we are happy to see the traction green construction is gaining from all quarters, and prefabrication is driving this change significantly.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)