Oil Condition Monitoring for equipment UPTIME

By Edit Team | February 18, 2023 11:39 am SHARE

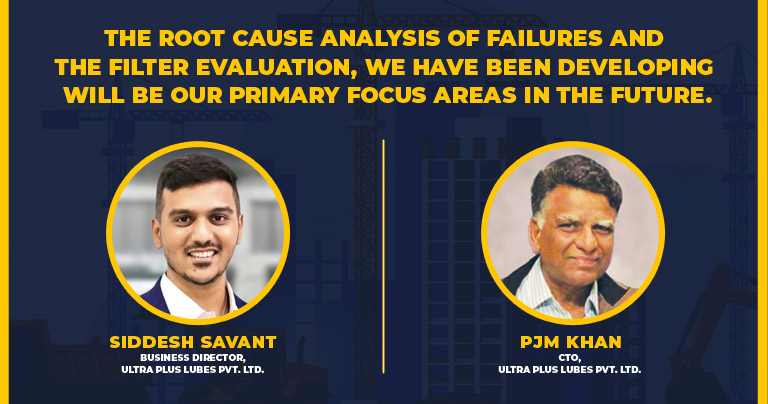

Mr Siddesh Savant and Mr PJM Khan of Ultra Plus Lubes explained the need for Lube oil analysis, Fuel and AdBlue testing in an exclusive interview with B2B Purchase. They also briefed their focus on filter analysis primarily to improve the machine’s performance and increase its reliability.

What is Ultra Plus Lubes key core business strength and focus?

Ultra Plus Lubes Ltd was started as a consultancy organization for setting up Lubricant blending plants. In 1993 we set our own blending plant catering to various MNCs for meeting their blending requirements. In 2014, as an additional service to its existing customer base Ultra Plus Lubes started a commercial laboratory for testing used Oil, Fuel, Coolant and AdBlue. The core strength of this business is to provide accurate results and prompt services to its customers thru the concept of ACCURACY AND SPEED DELIVERED. Today it has grown from testing 300 samples per month to 4000 samples per month.

Can you talk about your testing facility and the parameters followed?

We’ve been in this industry for almost seven years now. We began this journey with about 300 samples a month and are now testing over 4000+ samples monthly. We have now moved to a new laboratory set up with a built-up area around 10,000 sq. ft. in Navi Mumbai. This new state of art laboratory has the latest testing instruments to ensure faster reports to our customers. Apart from standard testing, we have expanded our capabilities into performance testing instruments like CCS (Cold Cranking Simulator) Brookfield Viscometer and Four Ball tester.

Apart from testing of various liquids, we are also focusing on the interpretation of the reports. Our team consists of industry veterans with an extensive understanding of equipment hardware to ensure that our customers receive the correct interpretation of the oil analysis results. We further believe in educating our consumers on understanding the results and pinpointing the specific problem thru the oil analysis report.

What kind of training is required to perform oil analysis?

There is a huge lack of awareness in terms of oil analysis and its impact on the machine.

Training is one of the most critical components of developing and nurturing this business, hence ensuring that even the person who collects the oil sample knows the advantages of oil analysis is essential. Ultimately oil analysis is an investment with numerous benefits and offers huge dividends for our customers with increased availability of the machines.

What innovations are happening in testing?

Over the years the customer demands have been changing very rapidly. Today our customers do not want to wait even for a day for the oil testing reports and are looking for solutions. There are remote monitoring devices available in the market which can trigger any abnormality in the oil parameters through the sensors fitted on the engine/equipment. Going forward we feel that customers will rely on hybrid technologies viz sensor based and on-site laboratories to ensure faster and accurate results.

For more details visit: http://www.ultralub.co.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)