P20 Formwork Beam: economical, safe and effective

By Edit Team | July 16, 2018 10:16 am SHARE

Sharp Ply’s innovative concepts offers high level of product safety and optimum cost effectiveness

Sharp Ply, one of the well-known brands across India is majorly known for its deep involvement in the fields of architecture, building construction, interiors, sports flooring’s, automotive body building, industrial patterns and dyes/dies (confirm!) and packing and palleting. The company‘s headquarters is located at Bangalore and has a wide presence across India.

Sharp Ply has got a variety of products that caters to the construction industry from formwork to finish for the best results.

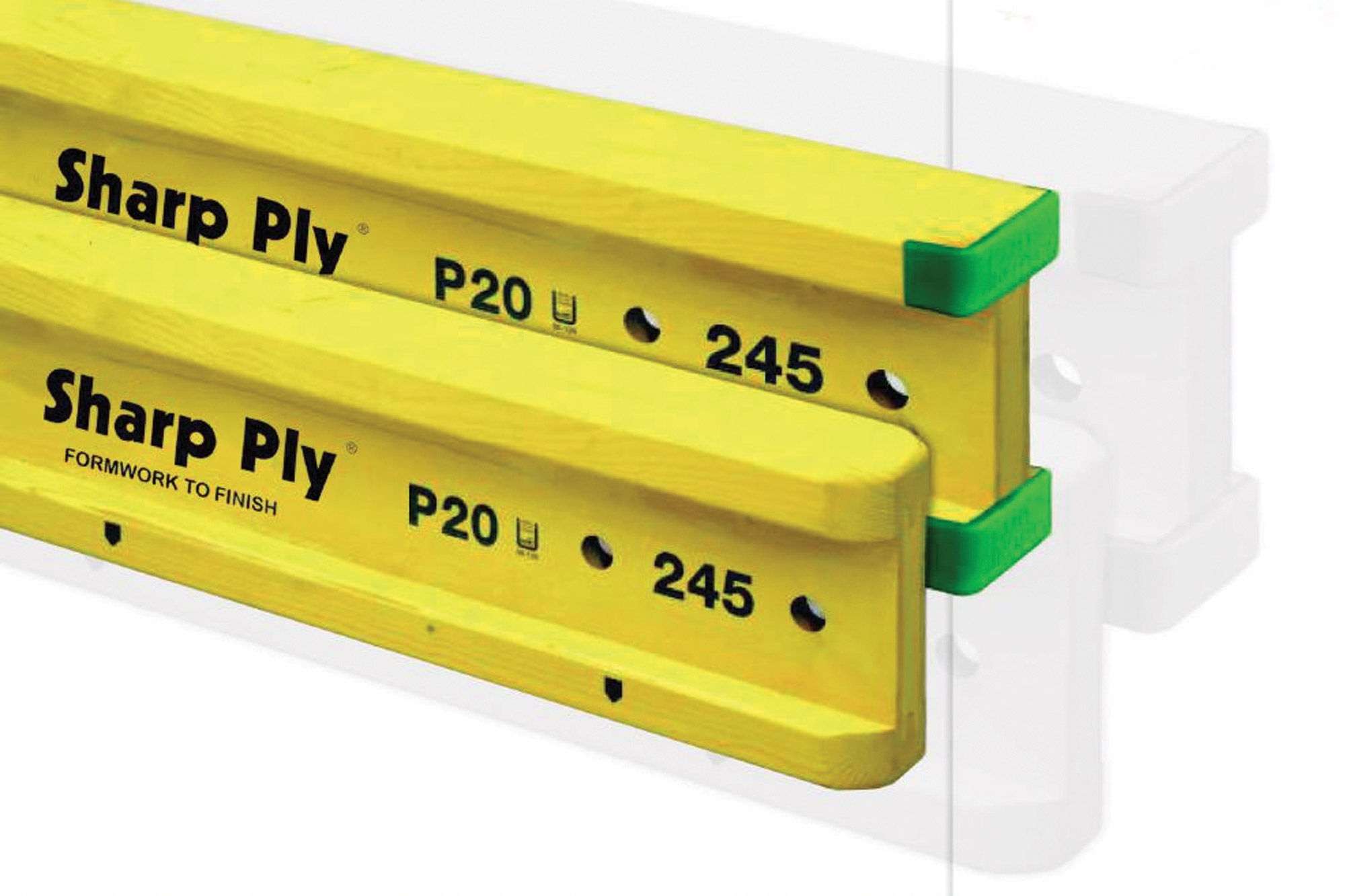

P20 Formwork Beam

In difficult working conditions at building sites – P20 Formwork Beam is considered to be one of the best options to use as it is economical, safe and effective. For more than 12 years, company’s family business is developing and producing P20 formwork beams at its production site in Polomka, Slovakia.

P20 Standard

Formwork beam produced according to European standard EN13377 with solid 27mm 3-ply web. P20 Standard beams offers high-level of product safety and an optimum cost effectiveness. They are easy-to-handle and proven in practise for efficient formwork construction.

Advantages

• High-loading bearing capacity at low weight

• Firm gluing (according to gluing certificate C)

• Highest safety level due to automatic sorting of raw material

Dimensions and tolerances

Technical specifications

Contact

Sharp Ply (India) Pvt Ltd

#33 ‘Suhani Villa’

Middle School Raod, V.V.Puram

Bangalore – 560004

Telephone – 080-26600117

info@sharpply.com

www.sharpply.com

P20

Standard P20

Premium Tolerance

Beam hight 200mm 200mm ± 1,0%

Flange height 40mm 40mm ± 1,5%

Flange width 80mm 80mm ± 1,5%

Web thickness 27mm 31mm ± 3,0%

Weight/Meter 4.5kg 4.7kg ± 1,5%

According

to EN13377 Carrying

capacity Characteristics

Shearing force Vk = 23,9 kN zul. Q = 11 kN

Bending moment Mk = 10,9 kNm Zul. M = 5kNm

Support Pb,k = 47,8 kN

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)