Schmalz reforms food handling with hygienic mGrip Finger Gripper

By Staff Report | November 23, 2024 12:26 pm SHARE

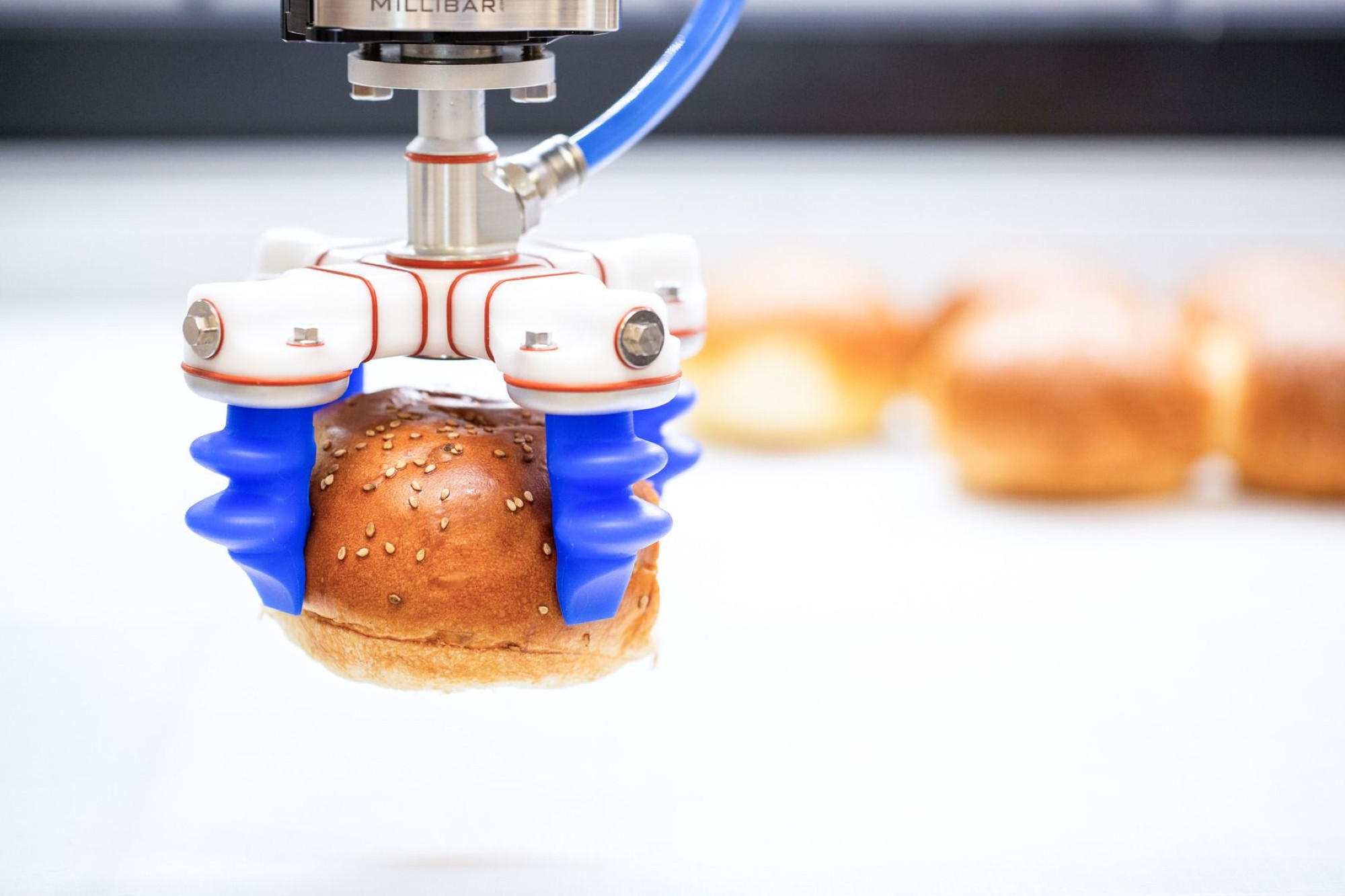

Schmalz’s innovative mGrip finger gripper offers a game-changing solution, combining a hygienic design with exceptional flexibility and precision.

Schmalz’s innovative mGrip finger gripper is constructed in a hygienic design and meets the highest cleaning standards. Its unusual design lets it pick up delicate things like vegetables or baked goods precisely and gently. This enables food manufacturers to automate their handling operations while maintaining process reliability.

Sensitive surfaces, sometimes soft, sometimes fragile, spherical or flat—food products come in a variety of shapes, making automated solutions difficult to implement. However, they all have one thing in common: the handling must be completely hygienic and hence safe. With its numerous configuration choices, Schmalz’s mGrip finger gripper always provides the best solution. Strong grasping is made easy with circular or parallel finger modules.

In contrast to mechanical solutions, the pneumatically controlled mGrip handles sensitive products with remarkable precision. Baked items, fruits, and vegetables, for example, can be safely placed in trays and removed for quality check. The gripper can safely pick up food in a variety of shapes and forms, including chicken drumsticks, thanks to its flexible structure. Companies outside the food business that want to pick up nets or sacks full of small parts benefit as well. This means that rapid picking can be implemented around the clock without the need to retain workers on standby for order picking.

Excellent process stability

The closed system maximises process dependability. The innovative finger gripper also meets the strictest cleanliness standards. They are simple to clean from the outside and meet the standards of CIP (Cleaning in Place) and COP. Schmalz has removed extra drives from the design, and the pneumatic circuit is closed. The sanitary design reduces the danger of contamination. The lightweight design makes mGrip ideal for use on cobots and other lightweight robots.

The gripper’s modular design, which includes different finger sizes and varied placements, opening angles, and forces, allows it to be easily customised to any task. This provides enterprises the greatest flexibility when processing various foods, particularly for usage in high-speed processes. As boring jobs are automated, they may deploy their workforce more efficiently. This reduces expenditures while also improving the application’s efficiency and quality.

For more information, visit: https://www.schmalz.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)