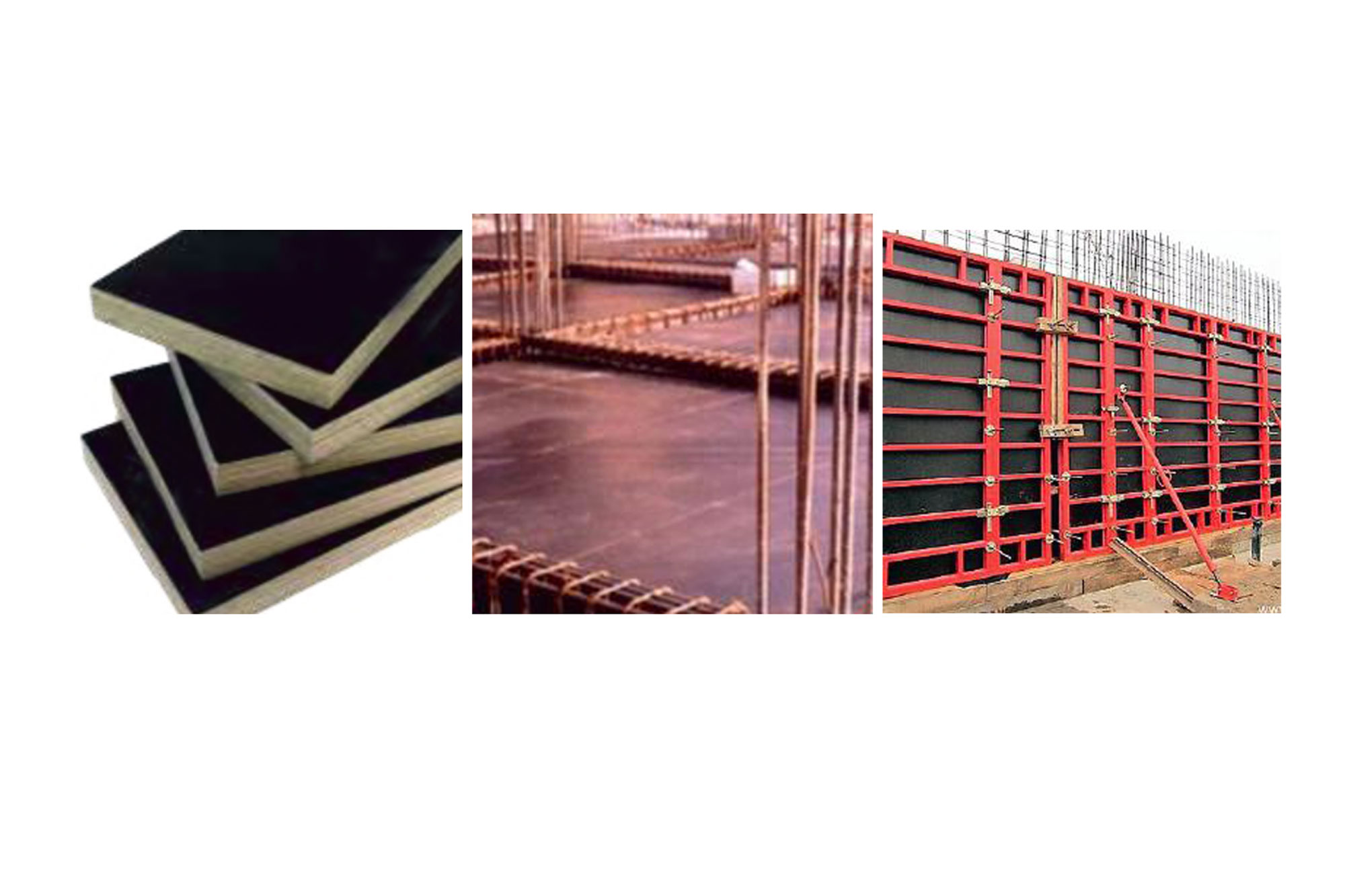

Sharp Ply Calibrated Sheathing Sheet

By Edit Team | July 15, 2019 4:19 am SHARE

Calibrated sheathing sheet is ultimate in plywood having excellent physical and mechanical properties. The rigid laminated surface not only prevents moisture absorption but also ensure excellent abrasion resistance in aggressive conditions and smooth finish to concrete formwork. It has been designed to suit any and every application needs of construction industry where durability, versatility, high bending strength, rigidity, stability, accuracy and tolerance to humidity parameters of performance value are critical.

Tips for optimum utilisation of shuttering plywood

Protect from weather: Store the formworks and the loose formwork panels against sun and rain.

Use standard tool: Film faced plywood can be cut shaped and drilled using standard wood working stools.

Seal edges and holes: Seal the resulting raw edges and holes with suitable water-resistant paint.

Oil panels before use: A suitable approved release agent must be used to ensure cleaner and easier striking and also more re-users.

Back face fastening: To achieve the best results, it is recommended that the plywood should be fastened to the formwork support members from the back of the panel.

Avoid falling from height: Plywood panels should be handled very carefully when moving high above the ground to prevent damages.

Clean after use: Plywood panels should be cleaned carefully with water or damaging the stream after use. Avoid damaging the panels surface when cleaning the concrete residues.

Contact

Aditya Chowatia, Executive Director

Sharp Ply India Pvt Ltd

# 33, Middle School Road, V.V. Puram,

Bengaluru – 560004, Karnataka

Tele: +91-80-26600117

Email: info@sharpply.com

www.sharpply.com

General Specifications

Items Value

Size 1,220 x 2,440 mm

Thickness 12 mm or 18mm

Wood Core Plantation Hardwood, Grade A

Type WBP or Class 3

Film Thickness Phenolic 130 GSM, Brown Colour

Density = 650 kg/cu.m. or = 630 kg/cu.m.

Technical Specification

No Properties Unit Values Testing Methods

1 Bonding Type Weather & Ball Proof-WBP (Class 3) EN 636:2003

2 Resin PF

3 Veneer Plantation Wood

4 Density Kg/m3 = 630 EN 323:1993

5 Overlay / Surface PSF > 130 GSM; Black Brown

6 Abrasive Test Rev 400 EN 438-2:2005

7 Thickness Tolerance mm +(0.2+0.03t)

-(0.4+0.03t) EN 315:2000

(f)nominal thickness

8 Thickness Swelling % =8% EN 317:1993

9 Formaldehyde Emission mg/m2h E1 EN 717-2:1995

10 Bonding Strength N/mm2 According to standard (>1.0) EN314-1:2004

11 Bending Strength

Parallel to the width of panel

Parallel to the length of panel N/mm2

>55(F55)

>30(F30) EN 310:1993

12 Modulus of Elasticity

Parallel to the width of panel

Parallel to the length of panel N/mm2

>6000(E60)

>3000(E30) EN 310:1993

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)