Sheetala Infrastructure: having a blast

By Edit Team | May 17, 2017 10:18 am SHARE

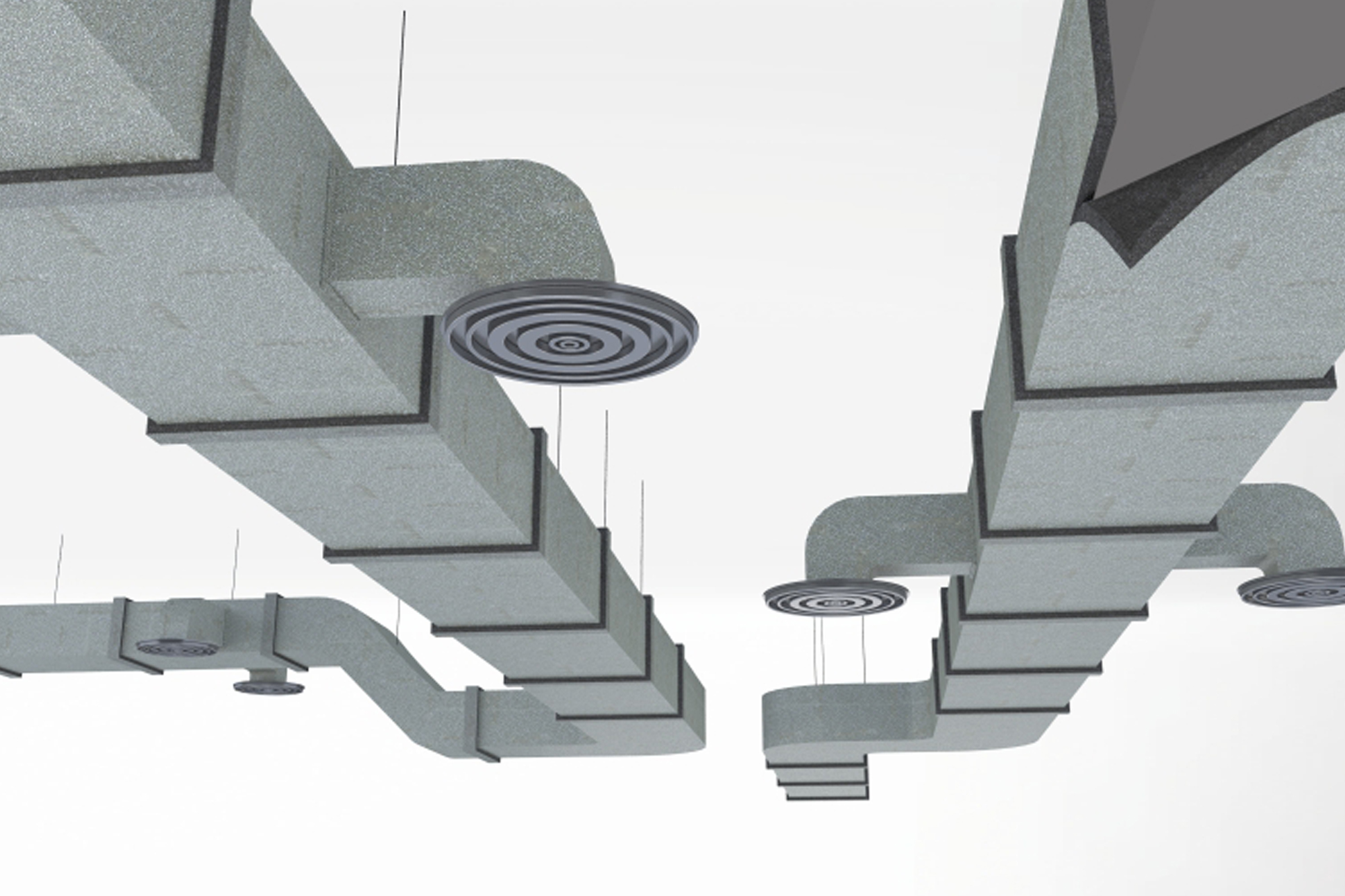

A jet blast deflector (JBD) or a blast fence is a safety device that redirects the high-energy exhaust from a jet engine to prevent damage and injury. The structure must be strong enough to withstand heat and high-speed air streams as well as dust and debris carried by the turbulent air.

Without a deflector, a jet blast can be dangerous to people, equipment and other aircraft. Till date, a few foreign suppliers held monopoly over this specialised product. The design was a closely guarded secret and was not shared by them nor were they willing to get it vetted by any Indian institutions. According to Sameer Khale, Owner, Sheetala Infrastructure Consultancy, “The problem was compounded when recently one of the jet blast deflectors was blown off during operations! Though it was not established that there was a design flaw, L&T started looking for options for their requirement of the deflector for BIAL (Bengaluru International Airport Ltd.) in India.”

He also adds, “As no one was manufacturing the deflectors in India, there was no data available on how to design these structures. We took the challenge and worked closely with experts from L&T and BIAL to establish the crucial parameters for design basis.” The company also received very valuable inputs from IIT Mumbai.

Factors such as type of the aircraft operating at the location, their frequency and proximity to the structure, temperature and chemical composition of the exhaust gases, and ambient wind conditions were considered.The analysis and design of structures subjected to blast loads require a detailed understanding of blast phenomena and the dynamic response of various structural elements.

Sheetala simulated the impact of the jet exhaust on the deflector using CFD (computational fluid dynamics), which was the basis of its design.

The final design was subjected to a detailed scrutiny by L&T, BIAL, its international consultants and IIT-Mumbai. After a lot of discussions and a few modifications, the design was finally approved, by all the 4 agencies involved.“

The entire structure is pre-fabricated in-house and assembled on-site as per international norms and safety procedures. The final product is a strong, sleek, a much more cost-effective structure, and well appreciated by the clients,” informs Mr Khale.

Contact:

Sheetala Infrastructure Consultancy Pvt. Ltd.

Email: info@sheetalainfra.com

www.sheetalainfra.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)