Sika has introduced the SikaShield W membrane, which can be installed over moist surfaces, requires minimal waiting time, prevents dust accumulation, and ensures uniform thickness, offering improved bond strength.

A successfully executed waterproofing project results from the right combination of 4Ms. Material (product), Method (application methodology), Men (skilled applicators), Machine (right equipment). While finalising the waterproofing system, the focus is often on product parameters (that too-high fascination with tensile and elongation). At the same time, methodology, workmanship, and equipment should be addressed in the discussions. Various unforeseen challenges are faced when work is practically executed at the site. The best product miserably fails when we start cutting corners to overcome these challenges to save time or money. Below are some of the many challenges often faced at sites.

High moisture and relative humidity: Waterproofing systems like liquid-applied membranes (polyurea, polyurethane, or acrylic), torch-on membranes, and peel-and-stick membranes are designed to be installed over dry surfaces. The product installation must wait until the surface moisture is within the permissible limit. Now consider a section of concrete cast today, then cured for 28 days. After that, there will be a long waiting time before the surface moisture reaches about 4% (which is mostly the upper limit for permissible surface moisture)! Projects that are already pressing for time only add to the woes of the project team.

Intermittent rains: Having gone through patient waiting for moisture to reach the desired level, the planning goes for a toss if there is an unexpected rainy spell!

Dust accumulation on intermediate coats or primer

3a. Liquid-applied membrane is done on a primed surface, and thickness is built up in multiple coats. Given our actual site conditions, the probability of dust accumulation over the intermediary coat is very high. Further, dust settling on freshly applied wet coats is very common in large open areas, and such accumulated dust is not easy to remove. This then leads to poor bonding in subsequent coats.

3b. In the case of torch-on membranes and peel-and-stick membranes, primer is applied to the surface, and the membrane is installed after the primer is entirely touch-dry. In this case, the likelihood of dust accumulation over primer is very high, and there is weak adhesion to the membrane.

High-cost Equipment: Certain product technologies require specific equipment for installation, which is cost-intensive. To avoid high-cost investment in equipment, improvisations are made on-site, often leading to impoverished outcomes.

Maintaining uniform thickness: In the case of the liquid-applied membrane, uniformity of thickness is often difficult to maintain and ascertain at the site. The product parameters declared by the manufacturer are based on tests done at defined thicknesses. Variations in the thickness of the applied membrane, unintentionally or otherwise, will always reflect on the performance of the applied waterproofing coating at the site work. To overcome these challenges without compromising the quality of work, Sika has developed an innovative solution, the SikaShiled W membrane. This innovative waterproofing system combines the advantages of a bituminous membrane with the universal application of a cementitious product. Sika Shield W membrane can be installed over moist and damp surfaces, requires minimal waiting time even in case of intermittent rains, eliminates the risk of dust accumulation between various layers, thus improving bond strength, can be easily installed using readily available equipment, and being a preformed membrane, uniform thickness at the site is assured.

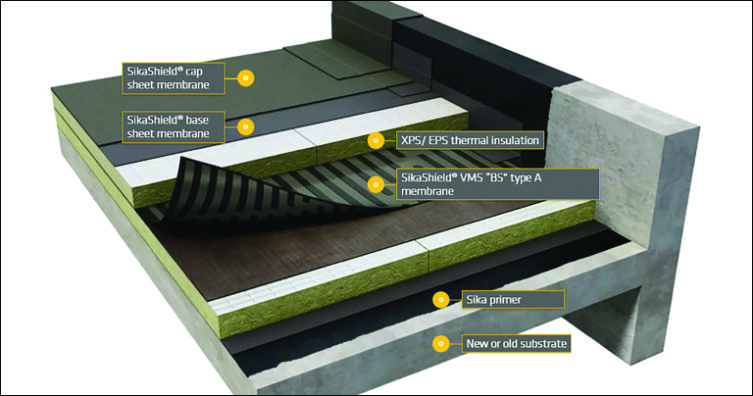

SikaShield® W membrane is a polymer-modified bituminous membrane fully bonded to the concrete substrate by a specially modified cement-based adhesive, SikaShiled® W1. The membrane comes with the option of two-side adhesion, with the option of a release liner provided on the bottom and the top faces of the membrane.

Installation: The SikaShiled W membrane is installed in three easy steps.

Where to use: SikaShiled W membrane can be used for vertical and horizontal applications.

For more info visit : https://www.sika.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.