Efficient water usage in industrial, domestic and agricultural sector through recycling, reusing, among other ways, is the need of the hour.

Rapidly increasing population, industrialisation and pollution against a backdrop of increasing climatic and non-climatic uncertainties are exerting enormous strain on existing freshwater resources. Maintaining a balance between the available resources and the ever-increasing water demand across all sectors presents a significant challenge nowadays. Hence, it is imperative to use and manage the available water resources in the most prudent and economical manner.

Water reuse and recycling

Reducing consumption, recycling, reusing water and utilising alternate sources of water in the domestic, industrial and agricultural sector is the need of the hour. Sewage and wastewater recycle, rainwater harvesting, etc are some ways of using water effectively. Wastewater recycle is rapidly gaining ground as a viable and dependable alternate source of water for specific purposes, says Spokesperson from Ion Exchange (India) Ltd.

Recycled water is a drought-proof, dependable, locally controlled and an additional source of water supply for industries making it one of the most effective solutions to help solve water scarcity. Escalating water shortages and rising water costs, coupled with tighter regulations on consumption of fresh water and discharge of wastewater, have significantly boosted the adoption of wastewater recycle by industry and municipalities as well as by residential/commercial/institutional complexes, hotels and resorts.

Efficient solar pumps can reduce the overall costs of the lifecycle, maintenance and negates the fuel or electricity costs. This optimises water usage while minimising the costs involved, says Sanjeev Sirsi, Associate Vice President of Water Utility, Grundfos India.

Grundfos’ demand-driven distribution is one such solution that helps detect and prevent water leakages in pipes thereby increasing water and energy savings. “The recycled water can be used for irrigation and in industrial processes thereby implementing economical usage of water,” he adds.

Water reuse is of paramount importance in the backdrop of droughts and erratic weather patterns. Water reuse can be a possibility when its contaminants are greatly reduced. Bio augmentation provides for an effective alternative for degradation of organic load in industrial wastewater, says Tejas Gathani, Vice President, Wastewater treatment Division, Organica Biotech Pvt Ltd.

Process water (generated from heating and cooling processes) contains minimal pollutant levels. It can be utilised for certain washing processes, process for pH adjustments. When the biological unit of a wastewater treatment plant works to its optimum efficiency, water expelled out is safe for environment. Industries can work in synergy and opt for sharing of water and treatment resources. Such synergies may result in reduction of input costs and wastewater treatment costs, Gathani adds.

India is one of the few countries to still use its freshwater reserves for flushing and cleaning, whereas other countries have long started using recycled water for these purposes. “Being stringent in using fresh water only for drinking will help reduce the water scarcity issues which India faces in many regions and having a mandate on only using recycled water for all other purposes will help in restoring water levels in all rivers and lakes”, says Nidhi Wagh, Manager, Sales and Business Development, QUA Water Technologies.

“We see both scarcity situations in urban and rural areas. We also lose lives due to flooding in the urban and rural areas when we receive torrential rains. The solution lies in better management of our resources. The need for building reservoirs and storing water during these abundant supplies and managing the stored water is not at the desired level,” according to V G Sakthikumar, Managing Director, Schwing Stetter India Private Limited.

Singapore has gone to the extent of recycling the wastewater to make bottled water for human consumption. Water starved Israel has implemented many techniques to convert their deserts to green covers by better water management. Even China, with its huge population has invested to make use of excess water that flows to the sea. Narmada project, Polavaram project and various water management projects in Telangana are good examples of India making effort to conserve water for better utilisation, informs Sakthikumar.

“As the agriculture is the biggest user of water resources in India, we should encourage modern methods of irrigation like drip irrigation, selection of crops that adds more value to GDP and uses less water, etc. Urban water scarcity is another big problem which can be effectively handled by wastewater recycling,” says Satya Narayana Y V V, Vice President, SFC Environmental Technologies Pvt Ltd.

Strategies for sustainable wastewater management

Ion Exchange’s extensive range of processes with an integrated approach, deliver complete solutions including wastewater treatment for every market – household, institutional, commercial, industrial and public water supplies, urban and rural, in India and overseas. Some of the specialised solutions for Industrial wastewater treatment include:

Industrial effluent treatment plants: The state-of-the-art completely automated wastewater treatment plants treat all internal process or utility wastewater and storm or fire water, with the objective of zero liquid discharge.

Zero Liquid Discharge (ZLD): Not only do the company offers advanced water and wastewater solutions that comply with discharge norms but also provide cost-effective effluent recycle and zero liquid discharge solutions. Industries that have installed the effluent treatment and recycle and zero liquid discharge plants have gained immensely by meeting strict compliance norms and have also gained excellent payback on their investment through assured quality of water for their process and utility needs. Offering widest range of processes and technologies – physio-chemical treatment, biological processes, membrane systems, thermal evaporators and solid waste (to energy) management systems.

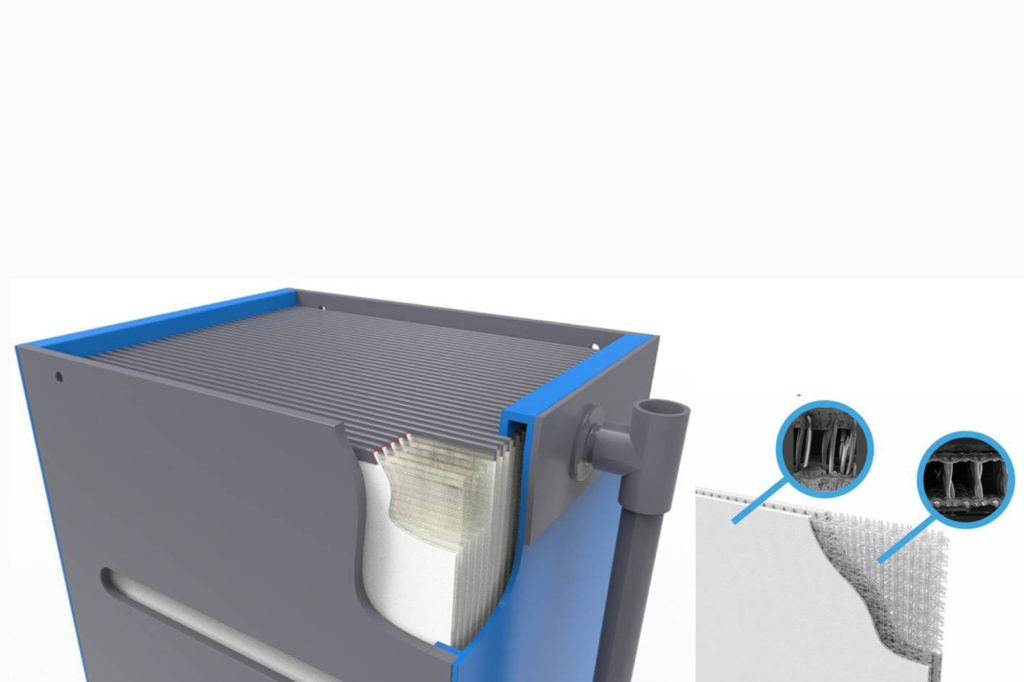

They also offer standardised solutions for wastewater treatment using a wide range of Bio processes like Membrane Bio Reactors (INDION MBR), Sequential Batch Reactor (INDION SBR), Fluidized Media Reactor (INDION FMR) etc.

INDION packaged sewage treatment plants – The INDION packages sewage treatment plants allow wastewater treatment and recovery and are a perfect fit for smaller industries, housing and commercial complexes, institutions etc as they are compact, user-friendly and minimise use of power and chemicals to treat and reuse sewage or wastewater. Their packaged sewage treatment plants are based on MBR, SBR AND FMR and an advanced version of attached growth process (NGPSTP- New Generation Packaged Sewage Treatment Plants).

Sustainable wastewater methods focus on the 4R’s (Reduction, Reuse, Recycling and Recovery) of water management. Using eco-friendly chemicals, decentralised treatment plants and energy efficient pumps and solutions are some of the methods that needs to be adopted, explains Sanjeev Sirsi, Associate Vice President of Water Utility, Grundfos India.

Grundfos offers solutions that caters to all the requirements of wastewater processes from collection to intermediate pumping stations, treatment, substance removal, disinfection, stabilisation and monitoring. Reliability is a critical dependency in wastewater treatment plants and Grundfos’ intelligent pumps and technology is an embodiment of the highest level of reliability. They are energy efficient and reduce overall life cycle costs.

Cleanmaxx is tailormade to suit the demands of all types of industries and municipal. The heterogeneity of microbes in Cleanmaxx ensures maximal degradation of diverse organic wastes, says Gathani.

Cleanmaxx hails microbes from GRAS (Generally Regarded as Safe) category and are completely safe for animals, plants and humans to handle. “Cleanmaxx confers the following benefits to the industrial treatment plants; maximum COD/BOD reduction, reduces recovery time after upset, breaks down recalcitrant chemical compounds, stable under high TDS levels and performs under variable pHand temperature conditions, adds Gathani.

QUA, being a membrane expert, has developed these products after years of R&D, and is now exporting them across the globe from its manufacturing facility in India. Q-SEP ultrafiltration (UF) and EnviQ Membrane Bio Reactor (MBR) is extensively used in recycling the tertiary treated water after STP and ETP, after which the water can be recycled or fed to RO for further process applications, says Wagh.

Schwing Stetter offers the complete solution of extracting wastewater and using the sludge for converting it into bio manure. The other option is to use the sludge as a feed for power generation. For India, bio manure is very useful as the manure is basic in nature and helps to utilise in the agricultural lands in India which are mostly acidic in nature.

“In city of Hollywood Southern regional wastewater treatment plant project, the process mixes dewatered biosolids with calcium oxide (quicklime) and sulfamic acid in solid granular form. The treated sludge is continuously fed into the plug flow reactor using a twin-cylinder piston pump. Temperatures in excess of 158 degrees Fahrenheit are maintained due to the reaction of the chemicals and sludge. In city of London, Ontario, the Schwing process takes dewatered sludge and routes it to a hopper, where quicklime and sulfamic acid is added to increase both the temperature and the ph. After a twin screw feeder in the basement mixes the material, an adjacent piston pump sends it to a reactor. There, the temperature and pH are raised to enough levels to kill off pathogens, says Sakthikumar.

SFC Environmental Technologies have success stories in Nagpur where Mahagenco is using 130 MLD of treated sewage for their power plant and in Surat where textile units are using 35 MLD of treated sewage in their processing units. Similar plants should be established in other cities where treated sewage can be used in power plants or other industrial units. Legislation should make it compulsory to reuse treated sewage water in nearby power plants, informs Narayana.

“Our company supplies SBR technology widely known as C-Tech. It is a biological treatment of wastewater for removal of organic matter (BOD/COD), Suspended Solids and Nutrients (Nitrogen and Phosphorous). C-Tech helps in achieving recyclable quality of wastewater with lower power consumption, lower area requirement and lower life cycle cost. The completely automated process control gives consistent good performance which is vital for a recycle plant. The technology is adopted widely in India in many sewage treatment plants, adds Narayana.

Effective reuse of treated wastewater

Reuse of wastewater can be an ideal choice for all – homes, industries and communities. The quality of treated water can be adapted to meet the needs of the sector. Treated wastewater can be economically beneficial as well as in many cities, treated wastewater is cheaper than standard piped water supplied by the utility. With ever increasing industrial tariffs, utilities face increasing price pressures to recover costs, and treated wastewater can be increasingly cost competitively.

Recycling wastewater is a reliable source of supply under conditions of water scarcity. In some areas where bans on groundwater use by industries have been introduced, reuse of treated wastewater is the ideal solution, informs Ion Exchange, Spokesperson.

The effectiveness of treated wastewater lies solely in how water recycled and reused for beneficial purposes such as non-potable (not for drinking) purposes and applications like cooling water for power plants and oil refineries, industrial process water for such facilities as paper mills and carpet dyers, toilet flushing, dust control, construction activities, concrete mixing, artificial lakes, agricultural and landscape irrigation, industrial processes, toilet flushing and replenishing a ground water basin (referred to as ground water recharge), says Sirsi.

Wastewater treatment can be tailored to meet the water quality requirements of a planned reuse. Recycled water for landscape irrigation requires less treatment than recycled water for drinking water, Sirsi further adds.

“With our technology maximum reduction in the pollutant parameters is achieved. This industrial expel is completely safe to be discharged in the environment,” says Gathani.

Reuse of treated water will be effective only if consumption of water from our natural resources goes down. With more and more focus on recycling and stringent norms of zero liquid discharge. Industries are now compelled to have a recycling plant because of two reasons, strict discharge norms have made it mandatory as well as limited access to fresh water for their process applications, informs Wagh.

Treated wastewater can be used for various applications like for watering the plants in the parks, for traffic areas and medians. It can be used for washing parking areas and roads, says Sakthikumar.

Recycling of wastewater can negate these costs as the wastewater is available right next to usage point. Another big advantage of wastewater recycle would be improvement in sanitation and protection of water bodies from pollution, says Narayana.

Using environmentally-friendly chemicals, decentralised treatment plants and energy efficient pumps and solutions are some of the methods that needs to be adopted.

Sanjeev Sirsi, Associate Vice President of Water Utility, Grundfos India

Bioaugmentation provides for an effective alternative for degradation of organic load in industrial wastewater.

Tejas Gathani, Vice President, Wastewater treatment Division, Organica Biotech Pvt Ltd

The need for building reservoirs and storing water during these abundant supplies and managing the stored water is not at the desired level.

Nidhi Wagh, Manager, Sales and Business Development, QUA Water Technologies

Treated wastewater can be used for various applications like for watering the plants in the parks, for traffic areas and medians.

V G Sakthikumar, Managing Director, Schwing Stetter India Private Limited

Urban water scarcity is another big problem which can be effectively handled by wastewater recycling.

Satya Narayana Y V V, Vice President, SFC Environmental Technologies Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.