Spartan focuses on world-class manufacturing

By Edit Team | August 16, 2019 6:02 am SHARE

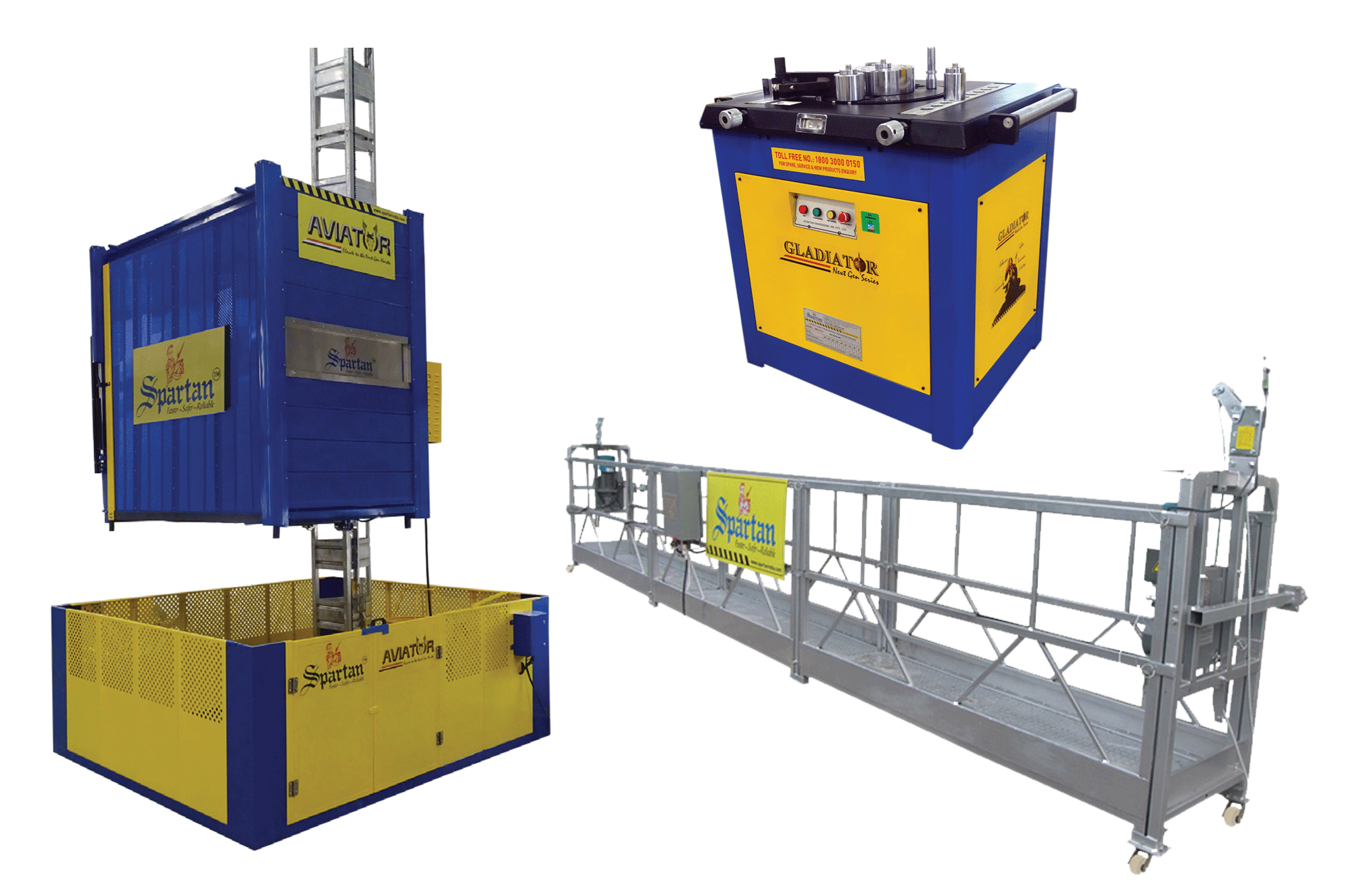

Spartan has played a pivotal role in the development of nation by providing machineries to infrastructure projects. The projects range from roads, flyovers, bridges, buildings, houses to dams and tunnels.

Exports to 10 countries worldwide, 7000 plus machines on site every year, 150 plus well-trained engineers and technicians, 20 national and international awards, 4000 plus satisfied customers and many more such milestones make one globe, one player – Spartan.

Spartan has achieved the distinction of being one of India’s most preferred and fastest growing construction equipment manufacturing company. The core purpose guides Spartan to strive hard and be on top of other manufacturers.

Spartan’s core purpose

To enhance the productivity, speed and safety in construction and infrastructure industry by providing advanced mechanised solutions, thereby saving their money, time and efforts.

Spartan aims at making a world-class manufacturing plant. This has led in forming “Operational Excellence Apex Committee”. This committee is led by the CEO, followed by department heads of production, design, quality, stores, purchase and administration. This committee takes various steps and initiatives to produce the best product in a productive and safe environment. This committee is implementing below mentioned initiatives to make this plant a world-class manufacturing plant:

Operational excellence in production

In Spartan’s factory 5S system is strictly followed and periodic internal audits are maintained. For operations, environment and personal safety, Spartan has achieved ISO 14001:2015 for Environment Management System and OSHAS 18001:2007 for Occupational Safety and Health Analysis System. Spartan has won many awards like ‘Excellence in Operations Award’ and ‘Sarvottam manufacturer of Rebar Cut and Bend machines and Suspended Platform’ by BAI for operational excellence. Material Storage arrangement is done in accordance with FIFO system and ABC analysis.

Min-max level is also maintained for optimum inventory. The storage of each part is identified with specific location and codification for assembly which is followed by workers mandatorily.

Spartan has well trained team of technicians having 10-20 years of rich hands-on experience with leading construction companies. The experts are from both mechanical and electrical background at each location to serve the customers 24×7. Spartan has in-house training facility to impart training on safe usage and maintenance of machines to engineers and operators. Spartan has ERP backed Call Management System App. with dedicated service co-ordinators at National and Regional level to ensure timely response to customer calls. Spartan also has a dedicated Toll-Free Number: 1800 3000 0150 for current and prospective customers support and product requirement.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)