Tech efficiency

By Staff Report | August 13, 2024 5:27 pm SHARE

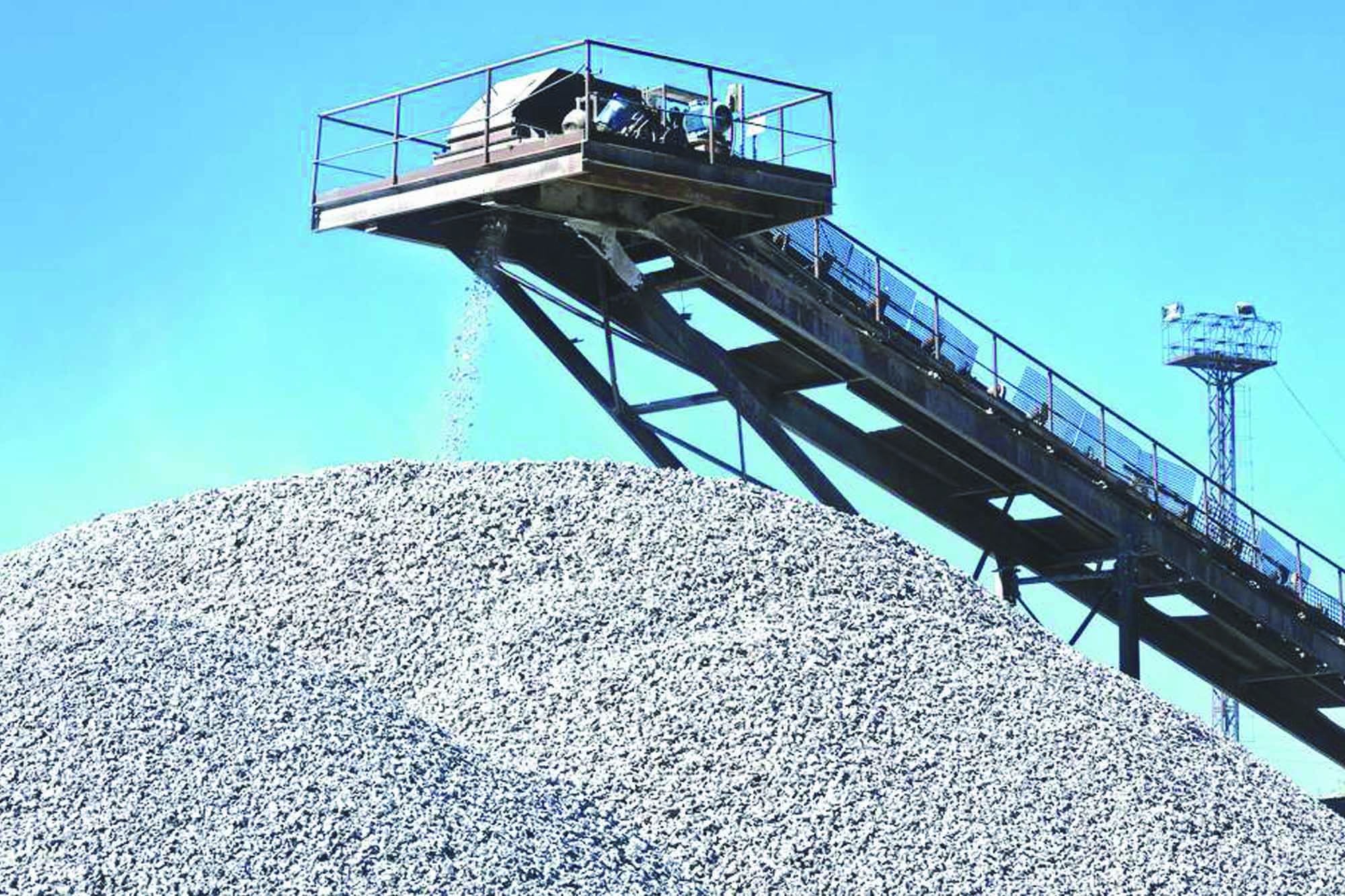

From anti-clogging screens to energy-efficient crushers, players in the crushing and screening sector are leveraging cutting-edge technologies to enhance operational efficiency, reduce costs, and improve environmental sustainability. This article delves into the insights shared by industry leaders on how innovation is reshaping the industry.

The crushing and screening industry is witnessing significant growth driven by rapid urbanisation, infrastructure development, and increasing mining activities. The global Crushing and Screening market was valued at USD 6449.6 million in 2023 and is projected to reach USD 8477.7 million by 2030, with a CAGR of 4.3 percent from 2024 to 2030. The mining industry dominates this market, accounting for 80% of the share, while sand and gravel aggregates comprise the remaining 20 percent.

This global growth trend is mirrored in the Indian market, which is experiencing a resurgence fuelled by a focus on customisation, quality, and comprehensive services. The acceleration of infrastructure projects and road construction is driving a projected 15 percent annual increase in demand for new crushing and screening equipment.

Technological breakthroughs driving efficiency

The industry is embracing technological advancements to address its customers’ evolving needs. Companies like Ashar Locker, Hailstone Innovations, Keestrack Crushers, MB Crusher, RD Infra Equipments, and Terex India are at the forefront of this transformation, introducing innovative products and solutions that set new standards in the industry.

Vasim Pradhan, Head Sales – India & International Business at Ashar Locker Pvt. Ltd., highlights how their ULTRA-FLEX Anti-Clogging Screens have revolutionised the industry. “Our anti-clogging screens combine polyurethane with steel, allowing each wire to vibrate individually, ensuring material passes through smoothly even in the wettest conditions,” he explains. This innovation has been particularly beneficial during the monsoon season when screening operations traditionally face significant challenges.

Sooraj Cherukat, DGM – Business Development and Sales at Hailstone Innovations Pvt Ltd, adds that their focus on advanced automation and cutting-edge production processes has resulted in rigid, efficient, and long-lasting machines. He emphasises that their equipment is designed to achieve the highest reduction ratio with the least power consumption, thereby lowering production and wear costs. Hailstone’s mobile crushing systems, particularly their trademarked SMART system, offer operational flexibility and reduced power consumption, making them a cost-effective solution for end users.

Terex India Private Limited has embraced automation to enhance the efficiency and accuracy of its crushing and screening operations. Ranga Swamy, Director of Customer and Product Support, explains how the company’s ACE Series automation system optimises processes by providing precise feedback and control. “Automation systems are critical for improving the efficiency of our operations, ensuring that processes are always optimised for peak performance,” says Swamy. Terex’s in-house “TRAC” device for online data collection and analysis further enhances material separation accuracy and efficiency. As the Indian market continues to evolve, the demand for such advanced automation solutions is expected to grow.

Sustainability at the forefront

Sustainability has become a central theme in the crushing and screening industry, with companies like Keestrack Crushers Pvt. Ltd. leading the charge. Deepak Pandit, Country Head at Keestrack, points out that their machines are designed with sustainability in mind. “We incorporate advanced dust suppression systems, energy-efficient drive technologies, and Tier 4 Final / Stage V compliant engines to minimise environmental impact,” he states. Keestrack’s diesel-electric and zero-drive options are particularly noteworthy, offering fuel savings of up to 40 and reducing the carbon footprint significantly. These innovations align with global trends toward greener operations and help clients meet stringent environmental regulations.

Rahul Deshmukh, Managing Director of RD Infra Equipments, also emphasises the importance of sustainability. RD’s focus on energy-efficient equipment and smart technologies like IoT and AI aims to reduce carbon footprints and enhance material recycling. “Our modular solutions are designed for versatility and customisation, allowing easy adaptation to various project requirements while maximising productivity,” Deshmukh notes. These efforts are complemented by a strong focus on safety and renewable energy integration, positioning RD as a forward-thinking player in the industry.

Productivity and operational efficiency

Enhancing productivity and operational efficiency is a key objective for companies across the sector. MB Crusher India Pvt. Ltd. has made significant strides in this area with its crusher and screening buckets, which enable onsite crushing and material separation. Piero Guizzetti, CEO of MB Crusher India, explains, “Our crusher buckets eliminate the need for material transportation and disposal, saving time and reducing operating expenses. This innovation streamlines workflows and boosts productivity, making our solutions indispensable in construction and mining.”

Keestrack’s commitment to operational efficiency is further reflected in its focus on product morphology and high reduction ratios. Pandit elaborates, “Our crushers are engineered to achieve superior product morphology and high reduction ratios, critical for maximising productivity in demanding environments.” Keestrack’s advanced crushing mechanisms and precise material size reduction capabilities ensure consistent output quality, particularly important in industries like concrete aggregate production.

Customisation and client-centric solutions

Customisation is becoming increasingly important in the crushing and screening industry as companies strive to meet the unique needs of their clients. Ashar Locker has made significant inroads by offering tailored screening media solutions. They conduct onsite audits to ensure customers use the right screening media at different stages, maximising plant efficiency. The company’s anti-clogging screens are highly sought worldwide, particularly for their ability to operate efficiently during the monsoon season. This period has traditionally posed significant challenges for the industry.

Hailstone Innovations also strongly emphasises customisation. Cherukat highlights its track-mounted and wheel chassis-based plants as examples of flexible solutions. “Our mobile plants offer greater operational flexibility, allowing them to be relocated quickly from one area to another,” he says. This flexibility is crucial in challenging terrains and when project timelines demand quick shifts in operations.

A path to innovation

As the C&S industry in India continues to evolve, the focus will likely remain on innovation, sustainability, and customisation. Companies are investing heavily in R&D to develop products that meet current demands and anticipate future challenges. The integration of advanced technologies like AI, IoT, and automation will further enhance operational efficiency and reduce environmental impact.

As infrastructural development and urbanisation accelerate in India, there will be a greater need for effective and environmentally friendly crushing and screening systems. Companies offering flexible, high-performance products while maintaining a strong commitment to sustainability will be well-positioned to lead the market.

India’s crushing and screening industry is pivotal, with technological advancements and sustainability initiatives driving the next wave of growth. As key players continue to innovate and adapt to the changing landscape, the industry is set to achieve new heights of efficiency, productivity, and environmental stewardship.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.